TOPTIG electric arc material increasing device and method for modifying aluminum alloy

An aluminum alloy and modification technology, applied in the field of aluminum alloy additive materials, can solve the problems of poor aluminum alloy performance and low forming efficiency, and achieve the effects of improving metallurgical properties, improving forming quality, and improving energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

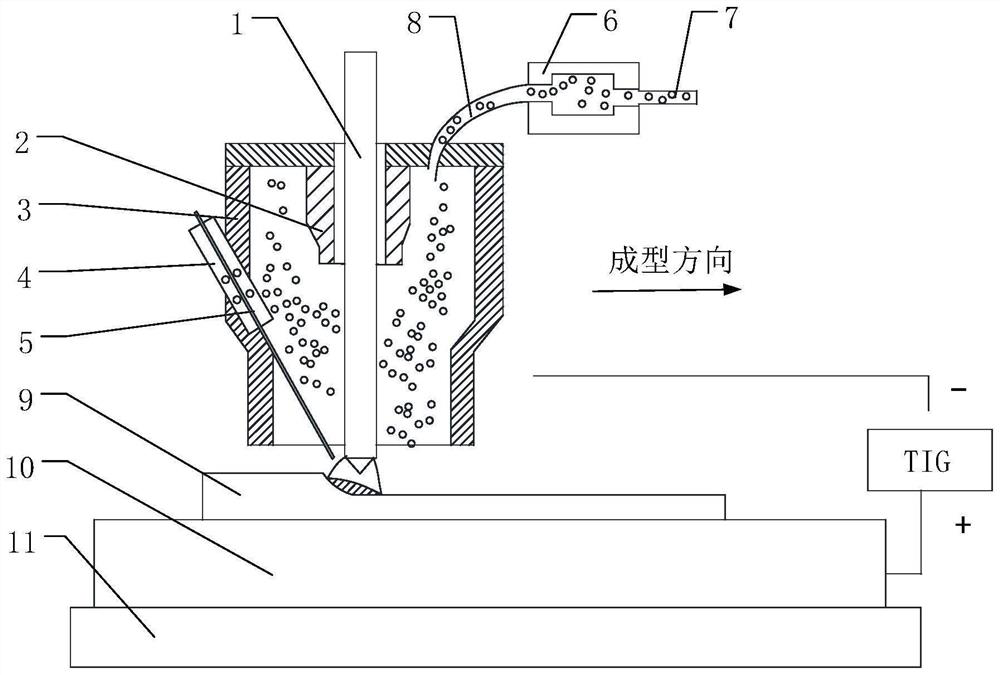

[0029] figure 1 It is a schematic structural diagram of an embodiment of a TOPTIG arc additive device and an additive method for modifying aluminum alloys according to the present invention. As shown in the figure, a TOPTIG arc additive device for modified aluminum alloy includes a nozzle 3, and a jacket 2 is arranged on the nozzle 3. The nozzle 3 is a funnel-shaped structure made of steel, the upper part is a cylinder and the lower part is a cone, which is convenient for gathering and spraying the metal powder. The bottom of the nozzle 3 is provided with a powder outlet, the nozzle 3 is located directly above the workpiece 9, and the metal powder is sprayed on the surface of the workpiece 9 through the powder outlet, and the workpiece 9 is added and modified. The nozzle 3 is arranged coaxially with the jacket 2 , and the top of the nozzle 3 is sealed and fixedly connected with the jacket 2 . The tungsten electrode 1 is located in the center of the jacket 2, and the tungsten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com