Laser cladding powder for 30CrMnSiNi2A steel and preparation method

A laser cladding, powder technology, applied in metal processing equipment, coating, transportation and packaging, etc., can solve the difficulty of ensuring the matching of laser cladding layer strength and toughness, high porosity of cladding layer, and cladding layer dilution rate. Advanced problems, to achieve the effect of excellent bonding strength, improve strength and toughness, improve toughness and crack arrest ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

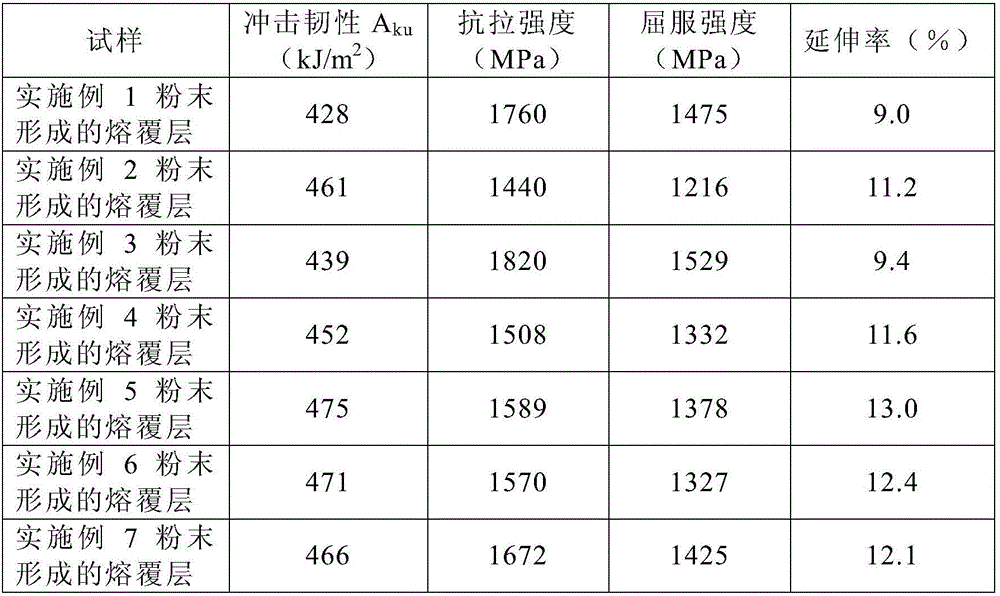

Examples

Embodiment 1

[0034] 30CrMnSiNi2A steel laser cladding powder, wherein, the amount of each component in the 30CrMnSiNi2A steel laser cladding powder is by weight percentage: Cr 0.8%, Mn 0.75%, Si 0.65%, Ni 2.0%, C 0.16%, Cu 0.15%, P 0.015%, S 0.01%, La 0.001%, and the balance is iron.

[0035] The specific preparation method is:

[0036] Step 1: Ingredients: Prepare the raw material 30CrMnSiNi2A rod and Fe / Ni / La alloy powder according to the weight percentage of each component in the above-mentioned laser cladding powder.

[0037] Step 2: Melting: Put the raw materials prepared in Step 1 in a high-vacuum protection electric furnace for melting under the protection of argon, the melting temperature is 1400°C, and the holding time is 12 hours to obtain an alloy melt;

[0038] Step 3: atomization: further atomize the alloy solution obtained in step 2, the atomization medium is an argon atmosphere at -15°C, and the atomization pressure is 3MPa; hydrogen gas is introduced at the same time durin...

Embodiment 2

[0041] A laser cladding powder for 30CrMnSiNi2A steel, wherein, the amount of each component in the laser cladding powder for 30CrMnSiNi2A steel is: Cr 0.85%, Mn 0.85%, Si 0.80%, Ni 2.3%, C 0.18 %, Cu 0.15%, P 0.015%, S 0.01%, La 0.005%, and the balance is iron.

[0042] The specific preparation method is:

[0043] Step 1: Ingredients: Prepare the raw material 30CrMnSiNi2A rod and Fe / Ni / La alloy powder according to the weight percentage of each component in the above-mentioned laser cladding powder.

[0044] Step 2: Melting: put the raw materials prepared in Step 1 into a high vacuum protection electric furnace for melting under the protection of argon, the melting temperature is 1400°C, and the holding time is 15 hours to obtain an alloy melt;

[0045] Step 3: Atomization: further atomize the alloy solution obtained in step 2. The atomization medium is an argon atmosphere at -14°C, and the atomization pressure is 3.5MPa; The volume ratio of hydrogen and hydrogen is 25:1; af...

Embodiment 3

[0048] A laser cladding powder for 30CrMnSiNi2A steel, wherein, the amount of each component in the laser cladding powder for 30CrMnSiNi2A steel is: Cr 0.90%, Mn 0.90%, Si 0.85%, Ni 2.50%, C0. 18%, Cu 0.15%, P 0.015%, S 0.01%, La 0.005%, Ce 0.003%, and the balance is iron.

[0049] The specific preparation method is:

[0050] Step 1: Ingredients: Prepare the raw material 30CrMnSiNi2A rod and Fe / Ni / La / Ce alloy powder according to the weight percentage of each component in the above-mentioned laser cladding powder.

[0051] Step 2: Melting: put the raw materials prepared in Step 1 into a high vacuum protection electric furnace for melting under the protection of argon, the melting temperature is 1400°C, and the holding time is 15 hours to obtain an alloy melt;

[0052] Step 3: Atomization: further atomize the alloy solution obtained in step 2, the atomization medium is an argon atmosphere at -13°C, and the atomization pressure is 3.5MPa; hydrogen gas is introduced at the same t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com