High-strength Al-Fe-Sc alloy capable of being used for laser additive manufacturing

An al-fe-sc, laser additive technology, applied in the directions of additive manufacturing, additive processing, process efficiency improvement, etc., can solve problems such as increasing the difficulty of preparation, low output, and easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

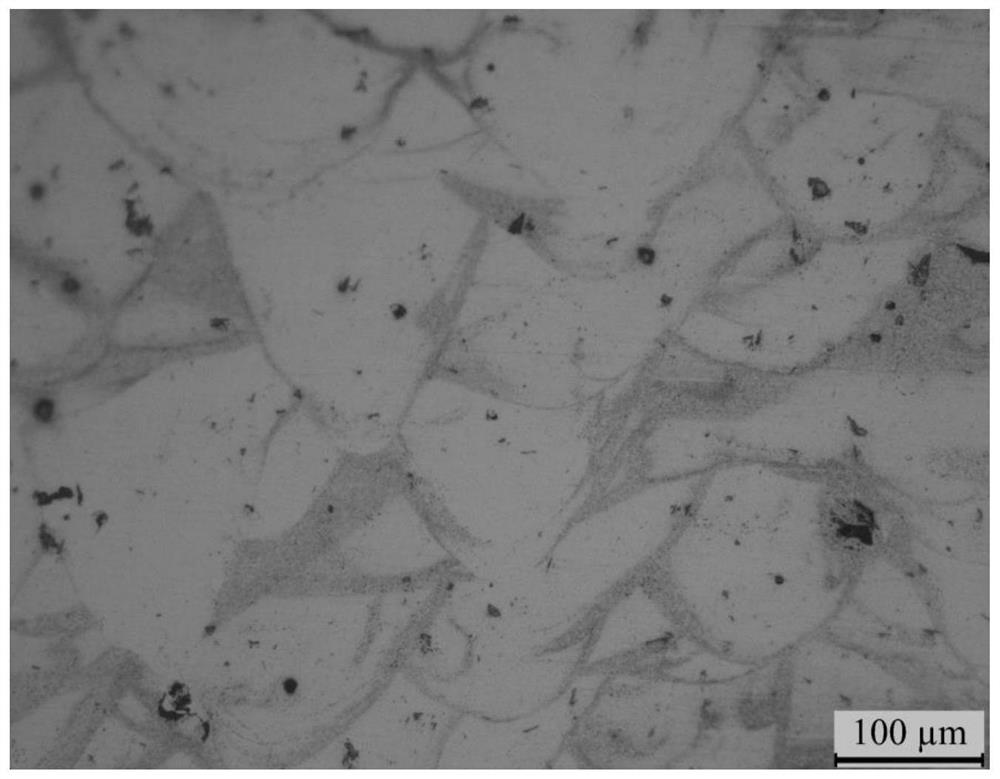

[0032] SLM printing Al-Fe supersaturated solid solution, containing the following components in mass percentage: Fe: 5.5wt%; Sc: 0.6%; Zr: 0.3wt%; Ti: 0.15%; Si: 0.28wt%; Mn: 0.3 %; Mg: 0.5wt%; Cu: 0.3wt%; the rest is Al.

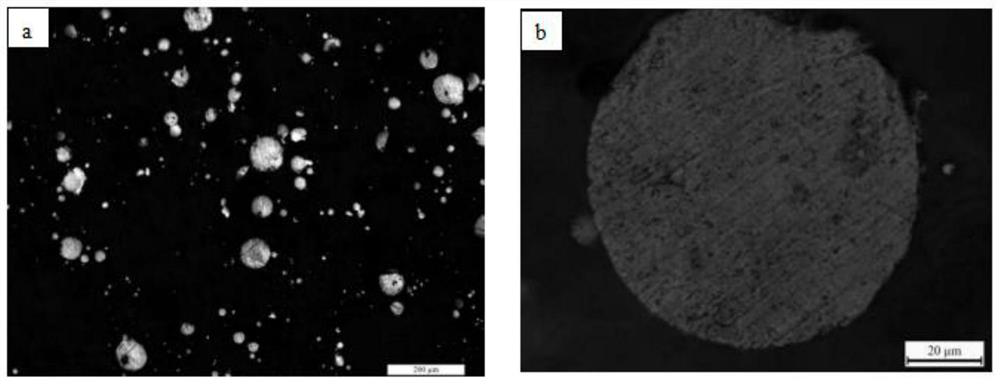

[0033]The 3D printing Al-Fe supersaturated solid solution powder with the above ingredients is prepared by vacuum melting, and then using argon atomization to make powder: the melting temperature is 850 ° C, and the pressure in the melting furnace is 0.6 MPa; then using argon as the medium to Metal droplets are atomized, and the atomization pressure is 8.5MPa. The particle shape of the prepared powder is spherical, and the powder of 15-53 μm is sieved, which can be used for SLM printing.

[0034] In a vacuum drying oven, the sieved powder was dried at 90°C for 8 hours, and the heating temperature of the substrate was increased to 300°C during printing.

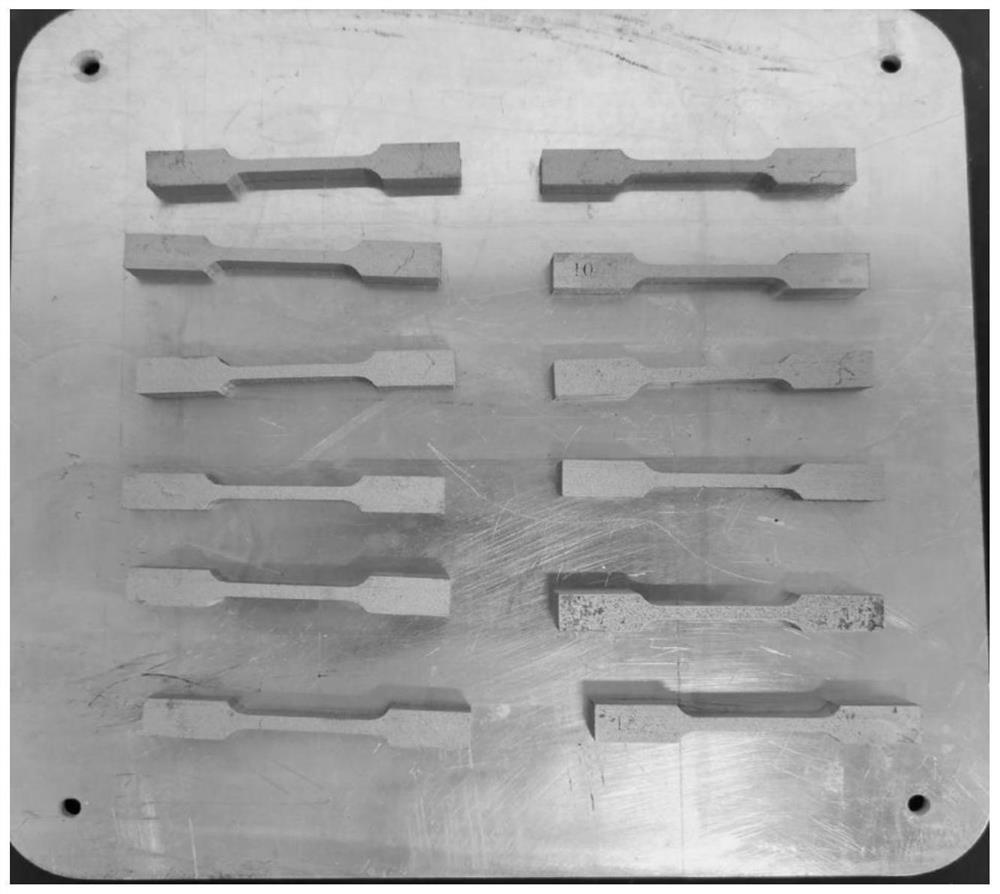

[0035] The above 3D printing aluminum alloy powder fiber laser SLM printing process is, laser power: 4...

Embodiment 2

[0042] SLM printing Al-Fe supersaturated solid solution, containing the following components in mass percentage: Fe: 5.5wt%; Sc: 0.5%; Zr: 0.2wt%; Ti: 0.15%; Si: 0.28wt%; Mn: 0.3 %; Mg: 0.5wt%; Cu: 0.3wt%; the rest is Al.

[0043] The 3D printing Al-Fe supersaturated solid solution powder with the above ingredients is prepared by vacuum melting, and then using argon atomization to make powder: the melting temperature is 850 ° C, and the pressure in the melting furnace is 0.6 MPa; then using argon as the medium to Metal droplets are atomized, and the atomization pressure is 8.5MPa. The particle shape of the prepared powder is spherical, and the powder of 15-53 μm is sieved, which can be used for SLM printing.

[0044] In a vacuum drying oven, the sieved powder was dried at 90°C for 8 hours, and the heating temperature of the substrate was increased to 300°C during printing.

[0045] The above 3D printing aluminum alloy powder fiber laser SLM printing process is, laser power: ...

Embodiment 3

[0048] SLM printing Al-Fe supersaturated solid solution, containing the following components in mass percentage: Fe: 2.0wt%; Sc: 0.6%; Zr: 0.3wt%; Ti: 0.15%; Si: 0.28wt%; Mn: 0.2 %; Mg: 0.3wt%; Cu: 0.3wt%; the rest is Al.

[0049] The 3D printing Al-Fe supersaturated solid solution powder with the above ingredients is prepared by vacuum melting, and then using argon atomization to make powder: the melting temperature is 850 ° C, and the pressure in the melting furnace is 0.6 MPa; then using argon as the medium to Metal droplets are atomized, and the atomization pressure is 8.5MPa. The particle shape of the prepared powder is spherical, and the powder of 15-53 μm is sieved, which can be used for SLM printing.

[0050] In a vacuum drying oven, the sieved powder was dried at 90°C for 8 hours, and the heating temperature of the substrate was increased to 250°C during printing.

[0051] The above 3D printing aluminum alloy powder fiber laser SLM printing process is, laser power: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com