Multifunctional lanthanum calcium manganese oxygen ceramic sintering furnace

The technology of lanthanum calcium manganese oxide ceramics and sintering furnace is applied in the field of electronic ceramics, which can solve the problems of inability to improve process efficiency, unstable sintering atmosphere, low utilization rate of gas source, etc., so as to improve the production range and performance of products and improve the gas source Utilization rate, excellent ceramic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

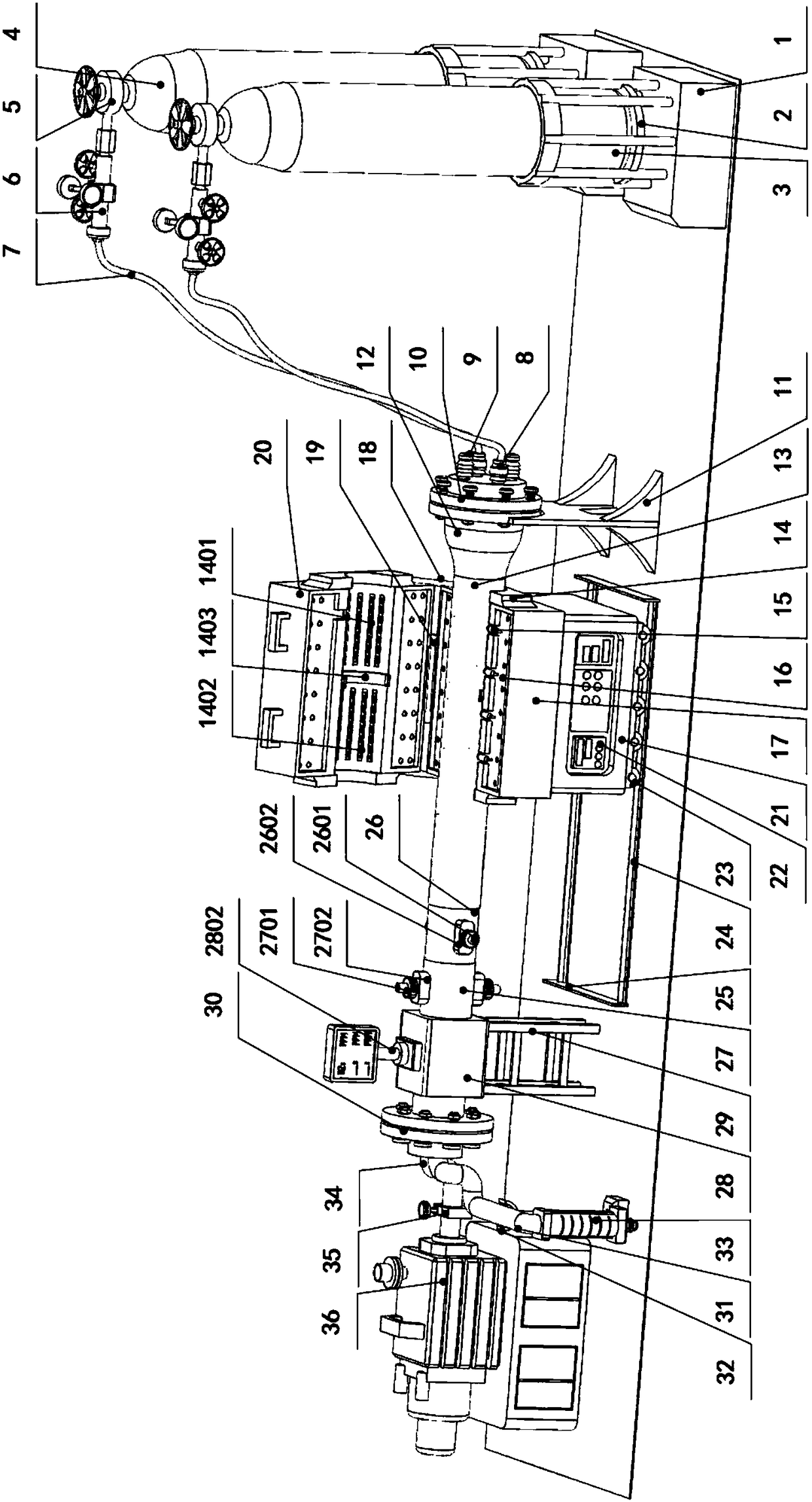

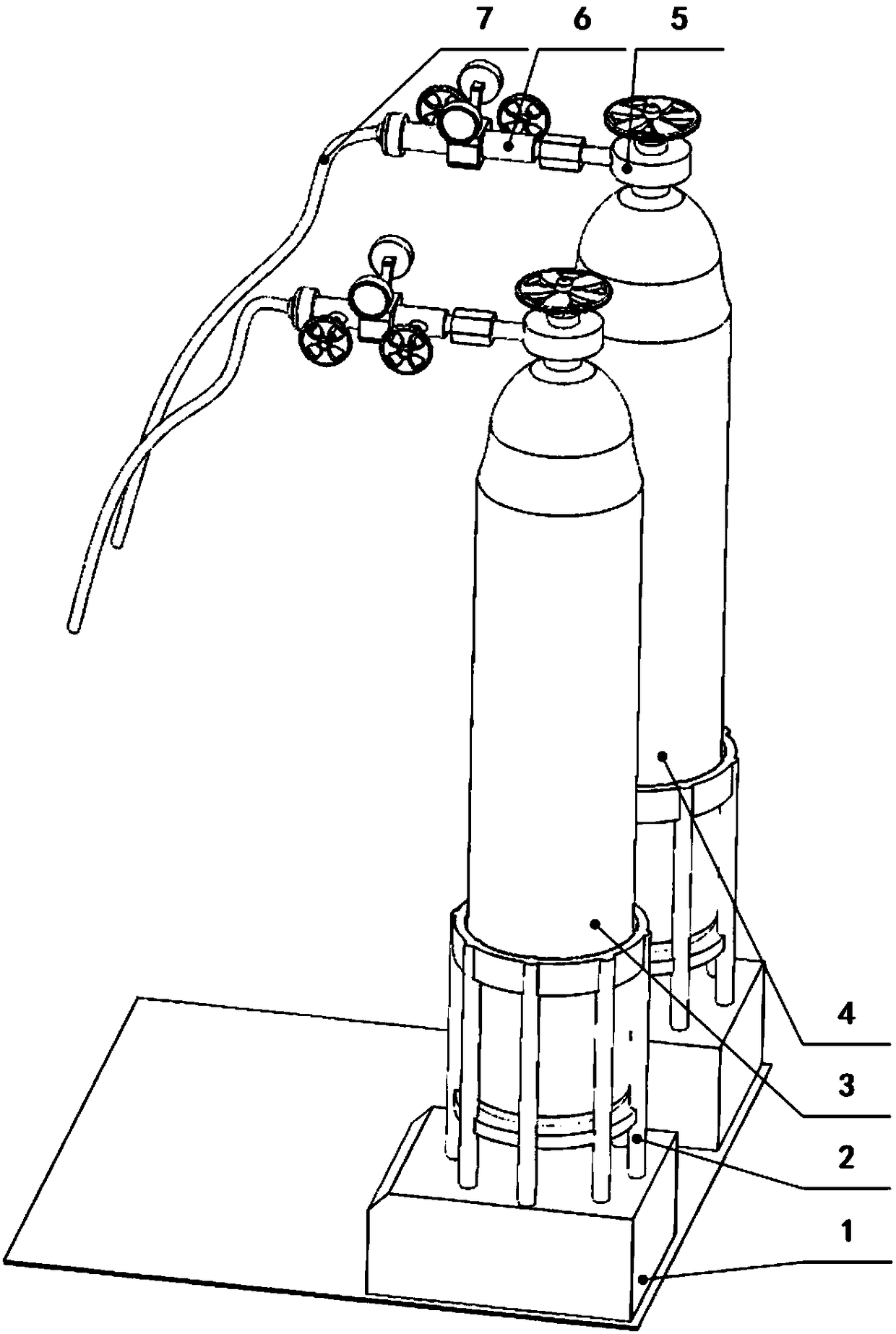

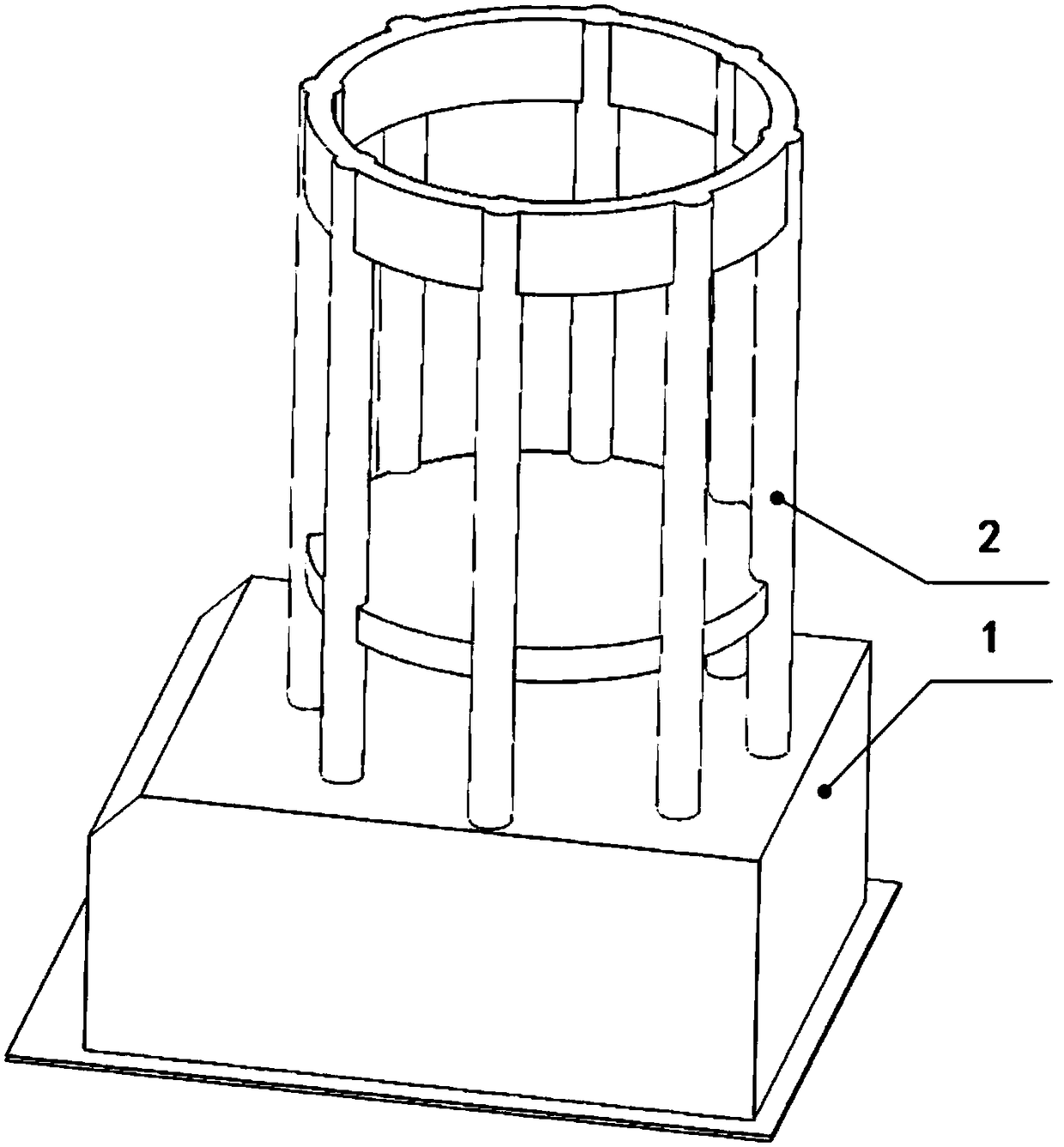

[0045] Example 1: Such as Figure 1-17 As shown, a multifunctional lanthanum calcium manganese oxide ceramic sintering furnace includes a bearing table I1, a bearing table II, a protective frame I2, a protective frame II, an oxygen cylinder 3, a nitrogen cylinder 4, a sintering pipe, a supporting rib 11, and a supporting frame 29. Sliding sintering system, monitoring chamber 28, vacuum pump 36, load-bearing platform I1 and load-bearing platform II are set on the ground, the protective frame I2 is fixedly set on the top of the load-bearing platform I1, and the oxygen cylinder 3 is vertically set in the protective frame I2 to protect The frame II is fixedly arranged on the top of the bearing platform II, the nitrogen cylinder 4 is vertically arranged in the protective frame II, the supporting rib 11 is arranged on the ground on the side of the bearing platform I1, the sintering pipe is arranged on the top of the supporting rib 11 and the sintering pipe is The ground is parallel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com