Sealed plasma melting furnace for treating medium- and low-level radioactive waste

一种等离子体、废弃物的技术,应用在放射性净化、废物处理、炉等方向,能够解决放射性物质泄漏甚至飞散等问题,达到提高设备效率、提高效率、保持安全性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The description of the specific structure or function disclosed in the embodiments of the present invention is merely an illustration for explaining the embodiments based on the concept of the present invention, and the embodiments based on the concept of the present invention can be implemented in various ways. In addition, it should not be construed as being limited to the embodiments described in this specification, but should be understood as including all modifications, equivalents, or substitutes belonging to the spirit and technical scope of the present invention.

[0029] Hereinafter, the present invention will be specifically described with reference to the accompanying drawings. The same reference numerals disclosed in the drawings denote components that perform substantially the same function.

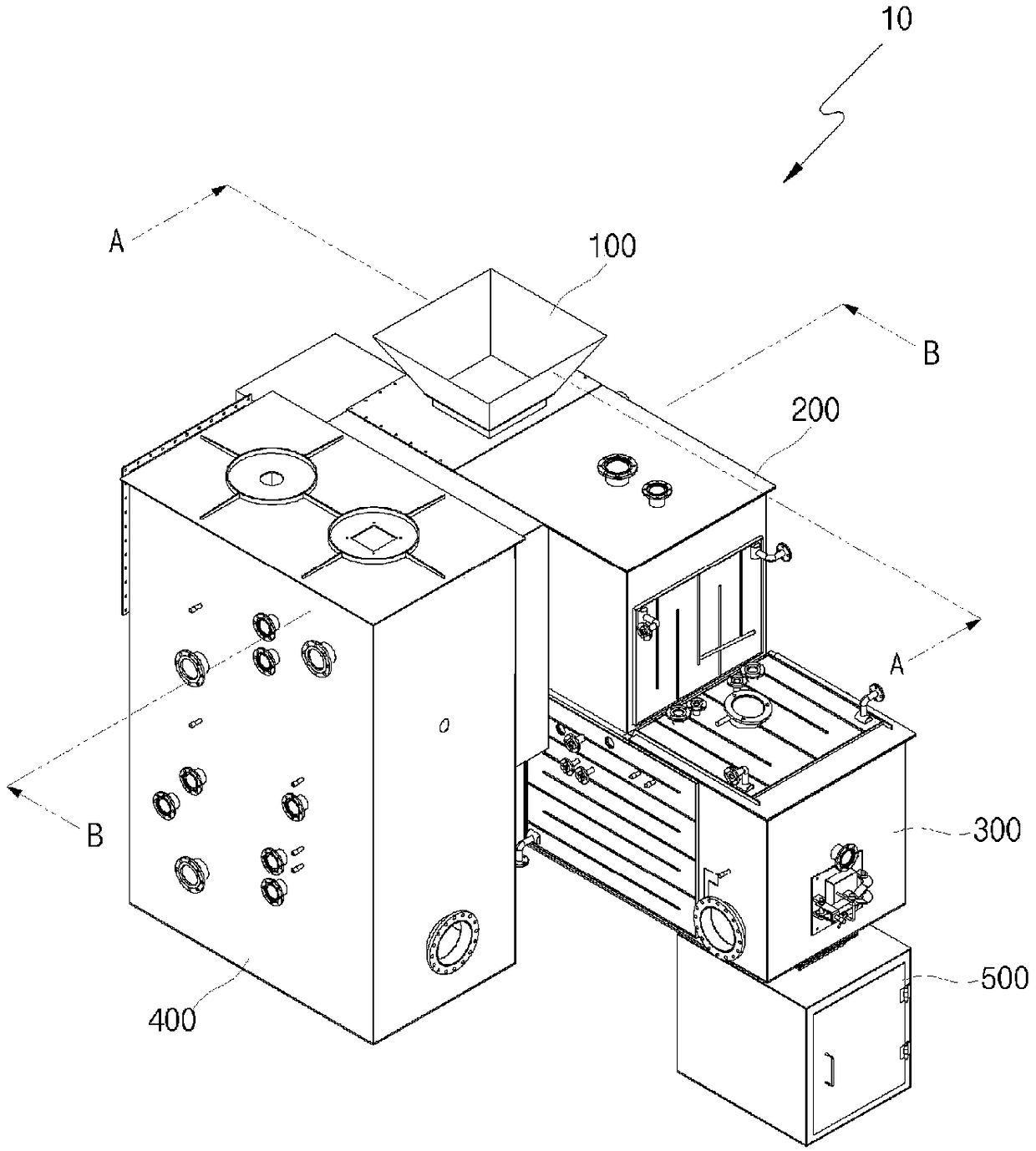

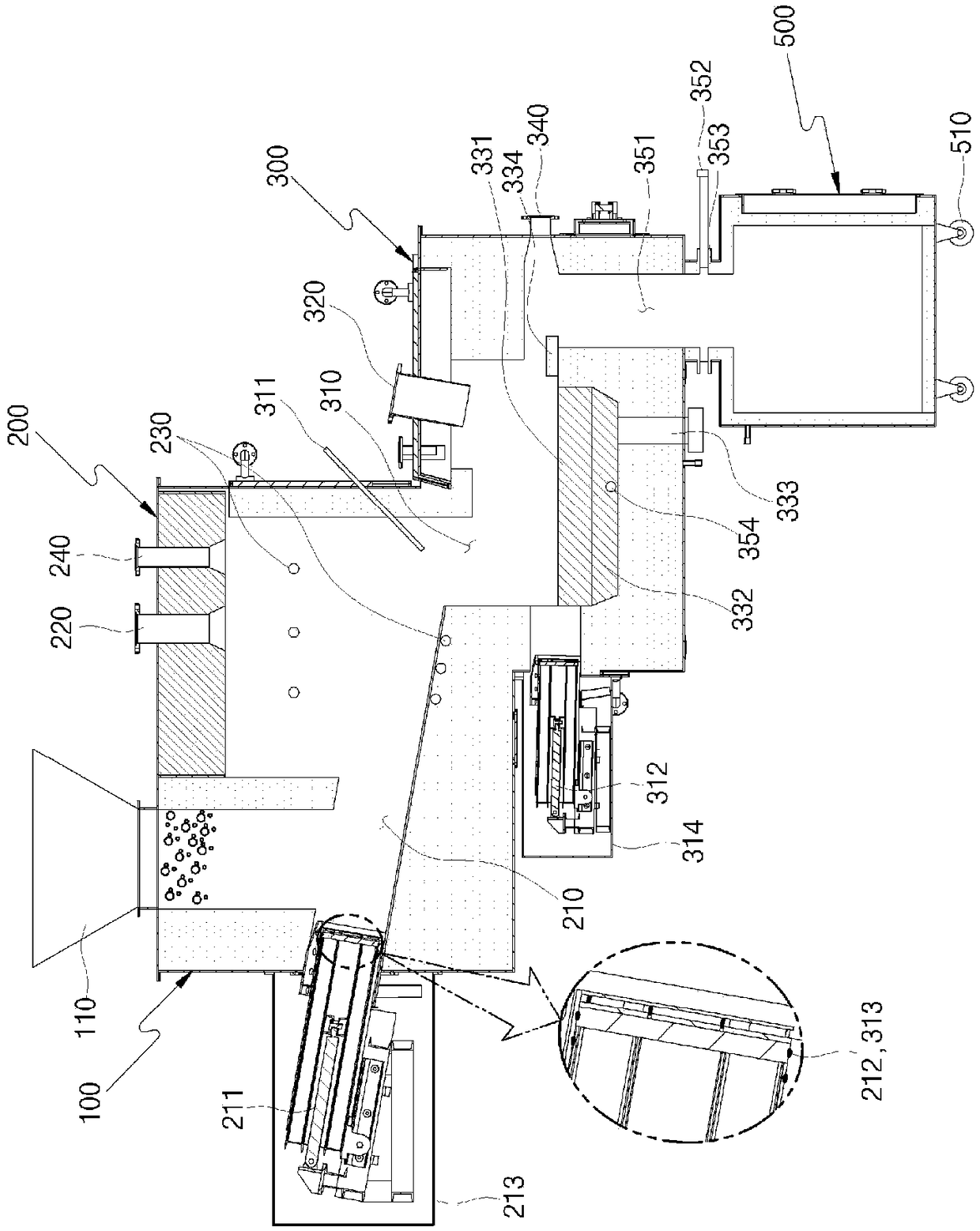

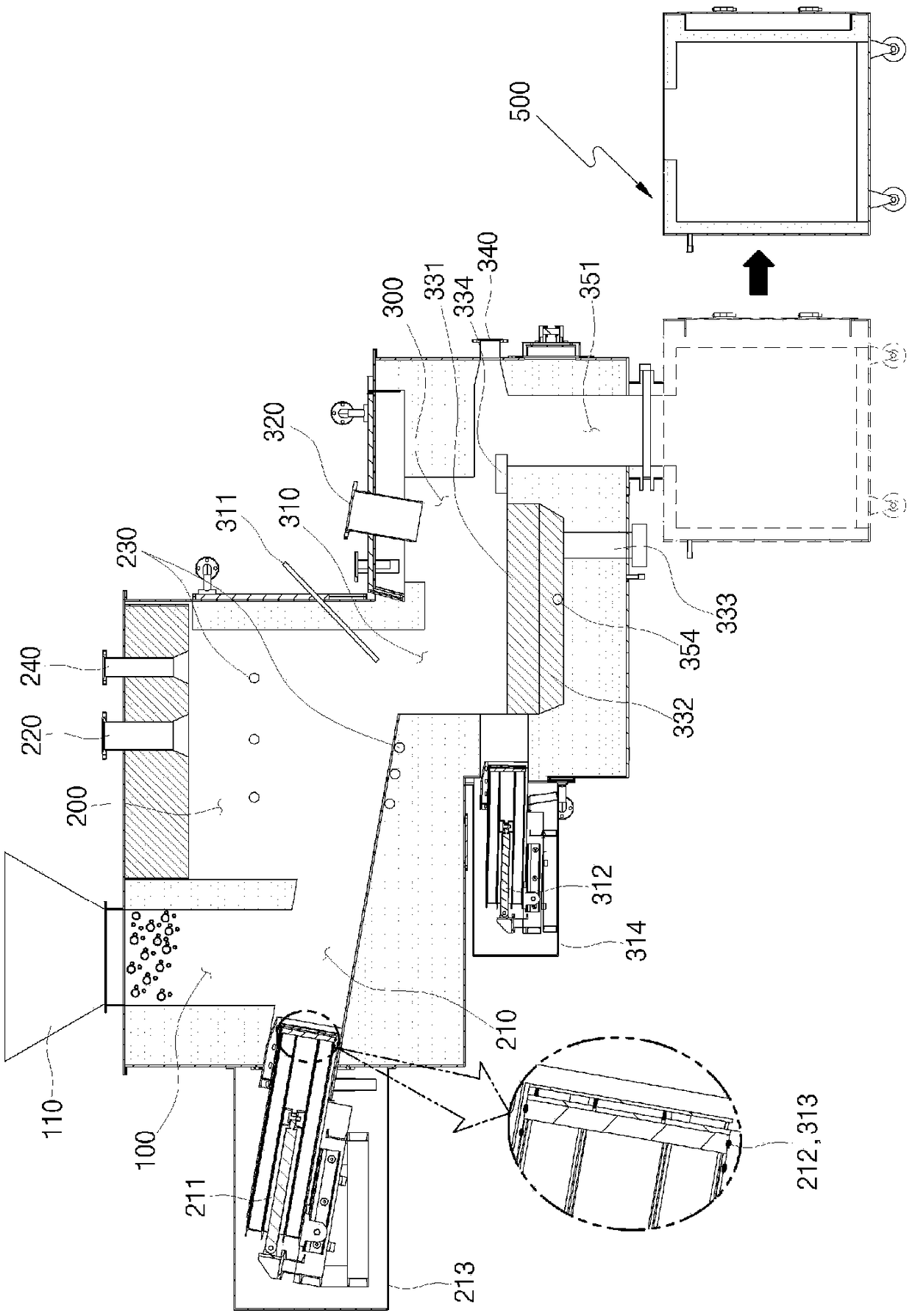

[0030] figure 1 It is a perspective view of a closed plasma melting furnace 10 for processing low and medium level radioactive waste according to an embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com