Production process and production equipment of high-stability fused cast zirconia-corundum brick

A zirconium corundum brick and production process technology, which is applied in the field of production equipment, can solve the problems of different content and high power consumption, and achieve the effects of reduced energy consumption, uniform materials, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

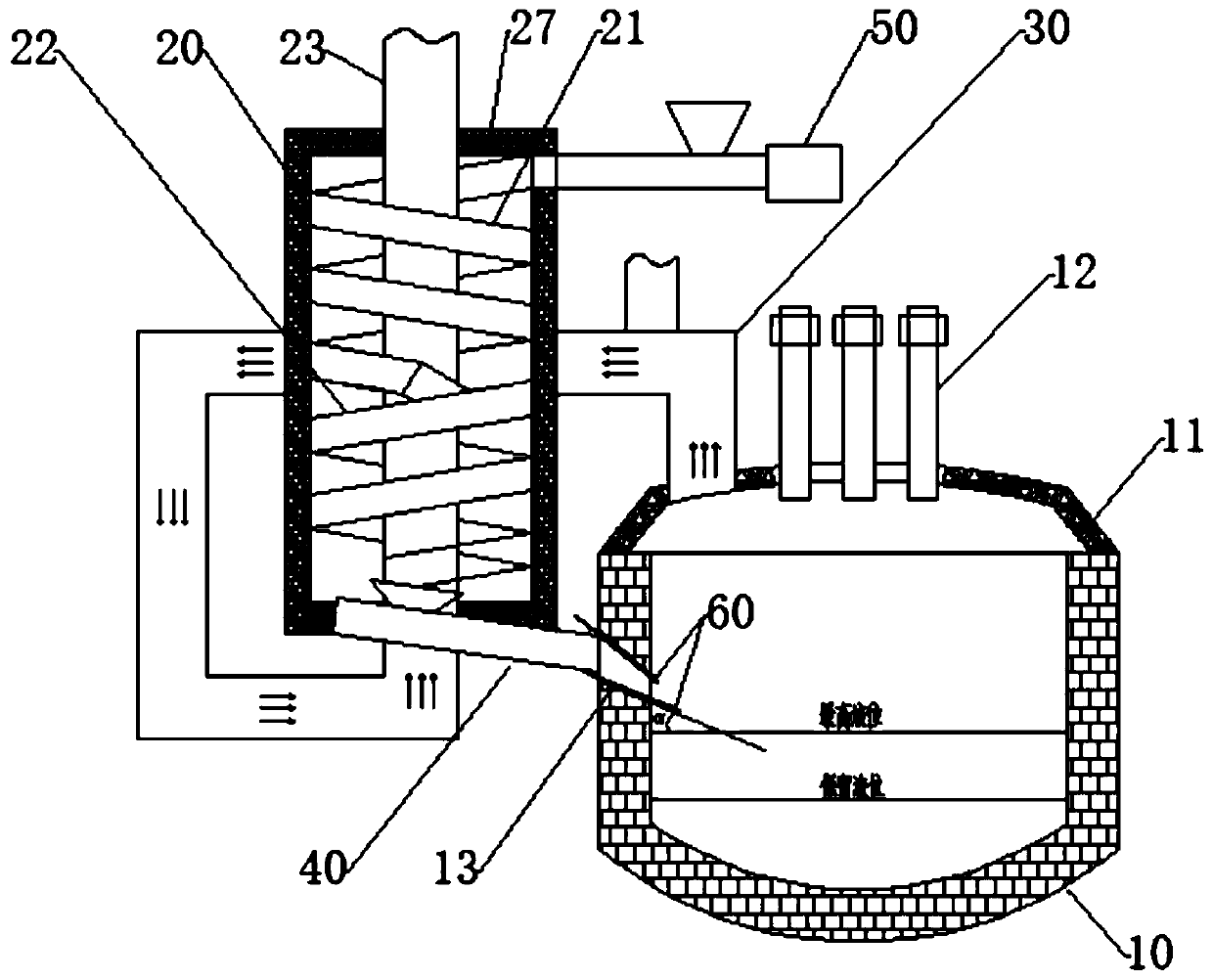

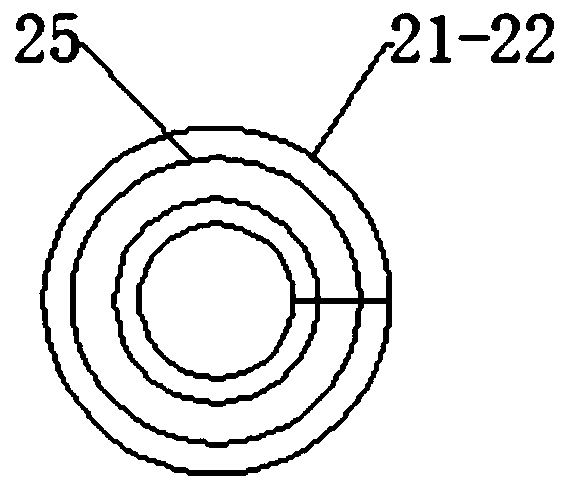

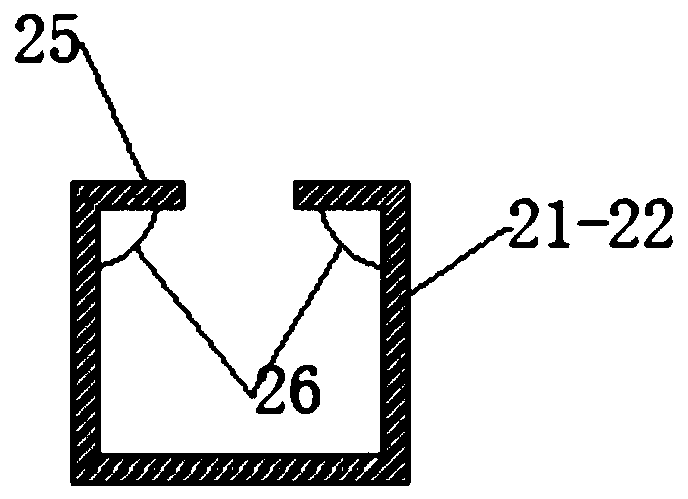

[0035] The invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0036] A high-stability fused-cast zirconium corundum brick production process, including mixture preparation, melting process, casting process, thermal insulation annealing process, demoulding processing process, wherein the ingredients are calculated by weight ZrO 2 +HfO 2 35-40 parts, SiO 2 12-14 parts, Na 2 O 1.2-1.6 parts, rare earth 0-3 parts, Al 2 o 3 Make up the ingredients to 100 parts by weight as the balance; the ingredients include clinker and raw meal, the ratio of the two is the same, the clinker is a block, the particle size is 3-8cm, and the raw meal is powder with a particle size of 0.05-1.5mm ; Clinker accounted for 10-30%;

[0037] The melting process: 1 / 2-3 / 5 of the molten material is kept in the furnace body 10, and the clinker is directly poured into the center of the furnace body through the hopper; the raw material is sent at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com