Ceramic brick sintering device for building

A technology of sintering device and ceramics, applied in furnace control device, charge composition/state, charging processing type, etc., can solve problems such as billet cracks, inconvenient control of temperature in the kiln, etc., to avoid cracks and reduce heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

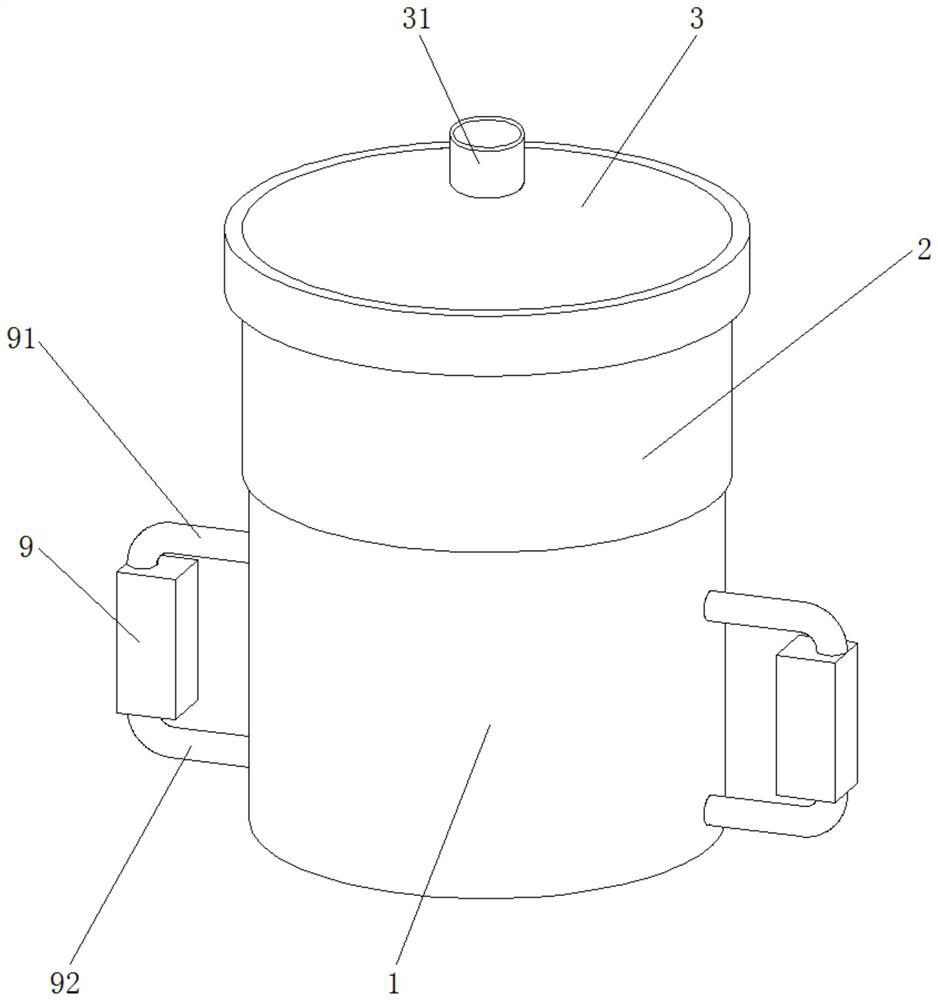

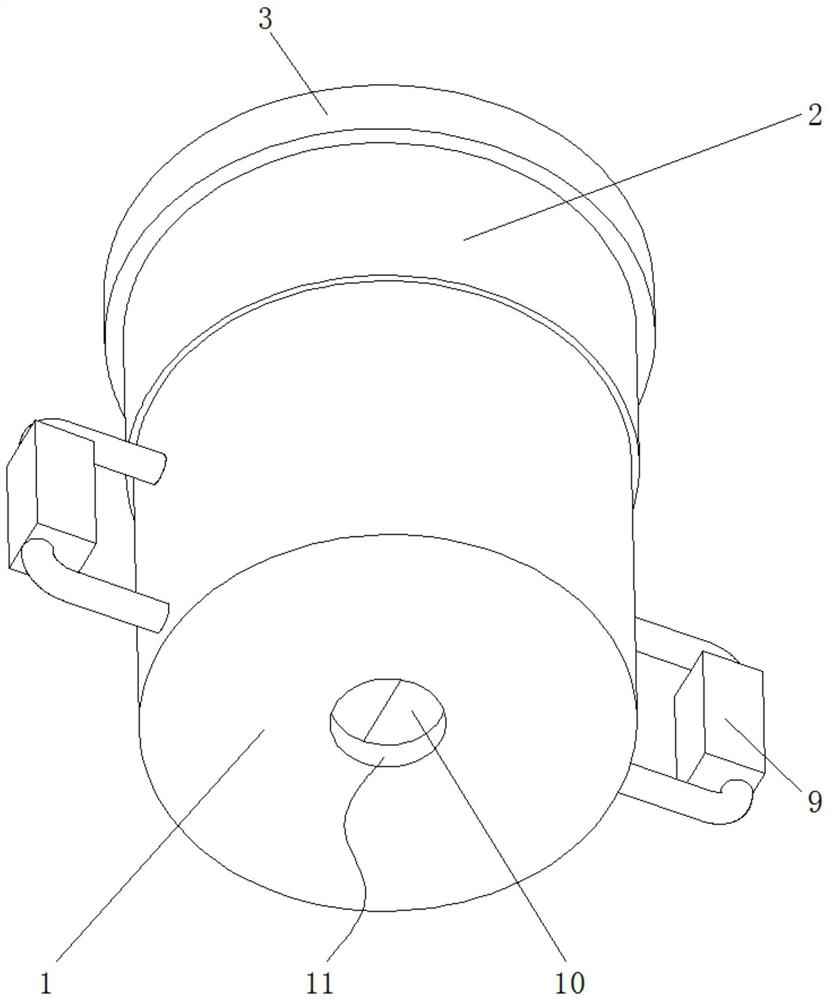

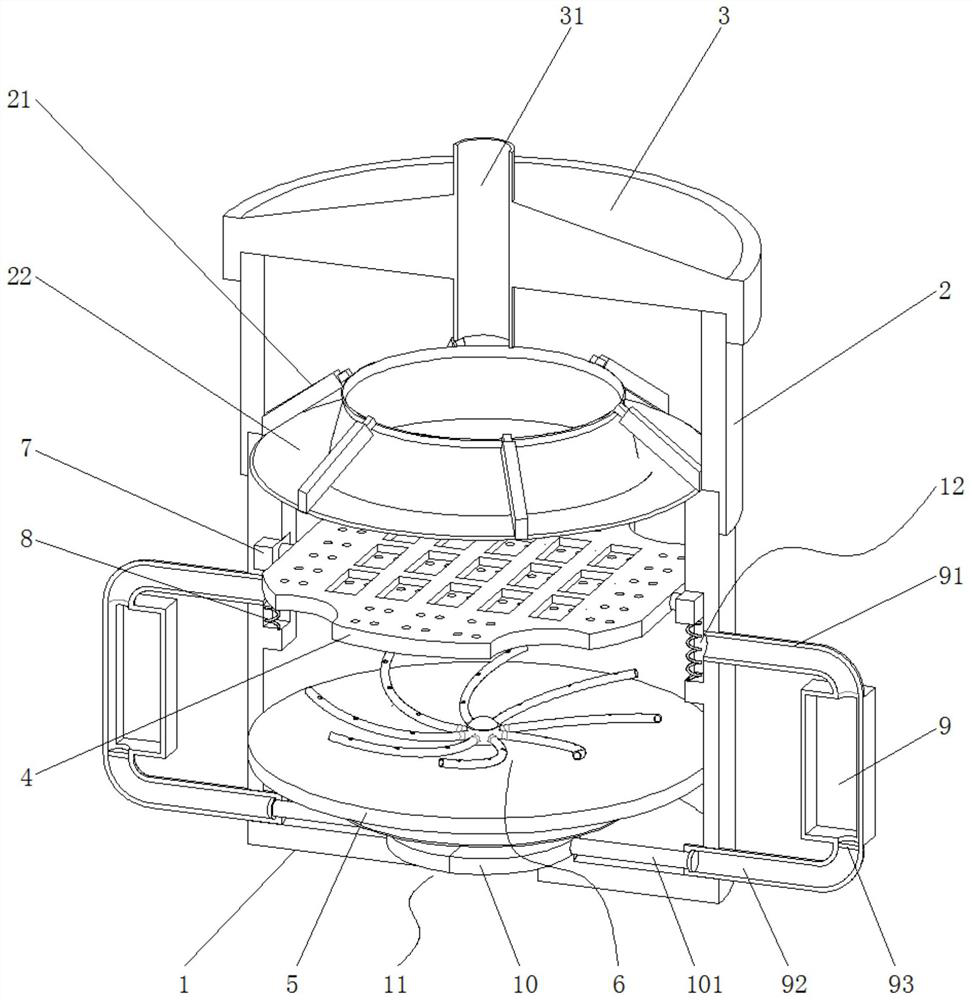

[0026] Embodiments of the present invention provide a ceramic brick sintering device for construction, such as Figure 1-7 As shown, it includes a kiln body 1, a tank body 2 and a top cover 3. An air inlet 11 is opened in the center of the bottom of the kiln body 1 . A combustion furnace is fixedly installed below the kiln, and the high-temperature airflow generated by combustion in the combustion furnace enters the kiln through the air inlet 11 . Because this is the prior art, so the concrete structure of the combustion furnace, connection mode etc. are identical with conventional technical means, do not describe in detail and no longer draw in the accompanying drawings.

[0027] The tank body 2 is fixedly installed on the top of the kiln body 1 , and the top cover 3 is fixedly installed on the top of the tank body 2 . The kiln body 1 is provided with a placing plate 4, and the placing plate 4 is used for placing ceramic bricks. The top of the top cover 3 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com