Method and device for sintering hollow ceramic microbeads

A technology of hollow ceramic microbeads and sintering devices, which is applied in the direction of ceramic products, ceramic material production, charging treatment types, etc., can solve the problems of wall adhesion and high energy consumption of hollow ceramic microbeads, and achieve good connectivity and low oil absorption rate , good electrical insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

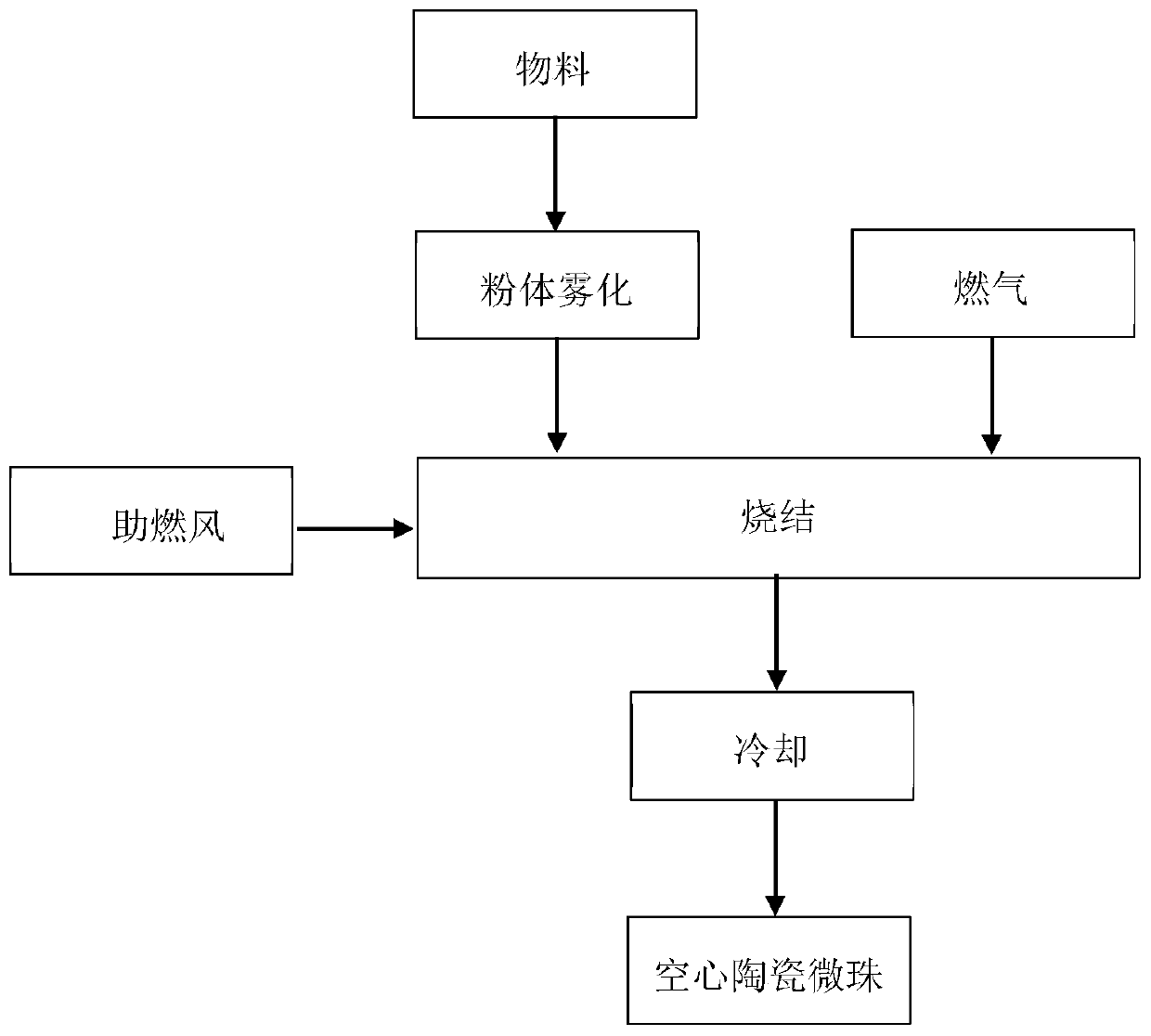

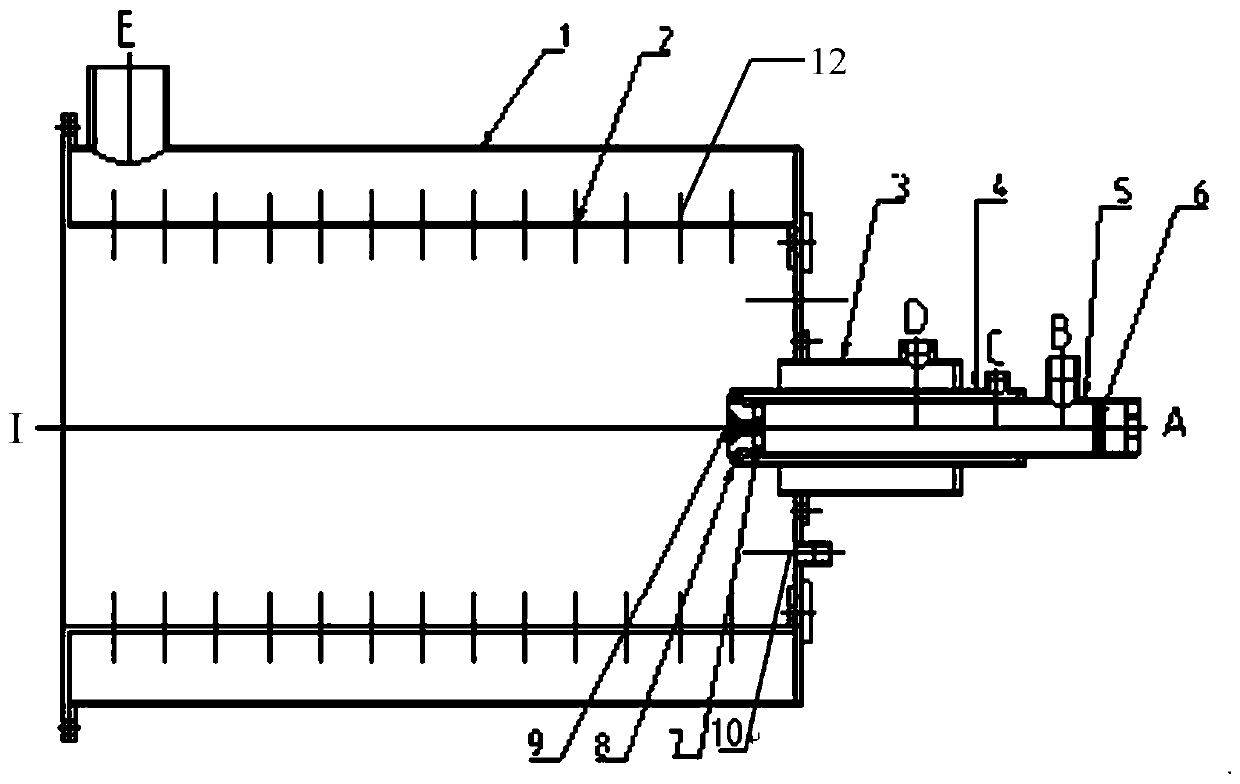

[0020] A method and device for sintering hollow ceramic microspheres in the present invention are mainly realized through the following technical scheme: the gas is allowed to enter the flame reaction zone evenly parallel to the axial direction, and at the same time, the combustion-supporting air enters the reaction zone perpendicular to the axial direction, and is rapidly mixed with the gas Mixing occurs violent combustion reaction to form a stable and continuous high-temperature flame; the material particles are uniformly dispersed to the flame reaction zone in an atomized state, ensuring a certain distance between the particles, and making the particles self-rotate at high speed, and the material passes through the high-temperature flame Rapid sintering, and then naturally cooled to room temperature, low-cost preparation of hollow ceramic microbead products with light weight, high strength, low oil absorption, good sound insulation, flame retardancy, electrical insulation, lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com