Heating furnace convenient to clean and maintain and high in energy efficiency

A heating furnace and high energy-efficiency technology, applied in the field of heating furnaces, can solve the problems of large manual labor, low utilization rate of heat energy, inability to disassemble, etc., and achieve the effects of timely cleaning and replacement, high utilization rate of heat energy, and easy disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

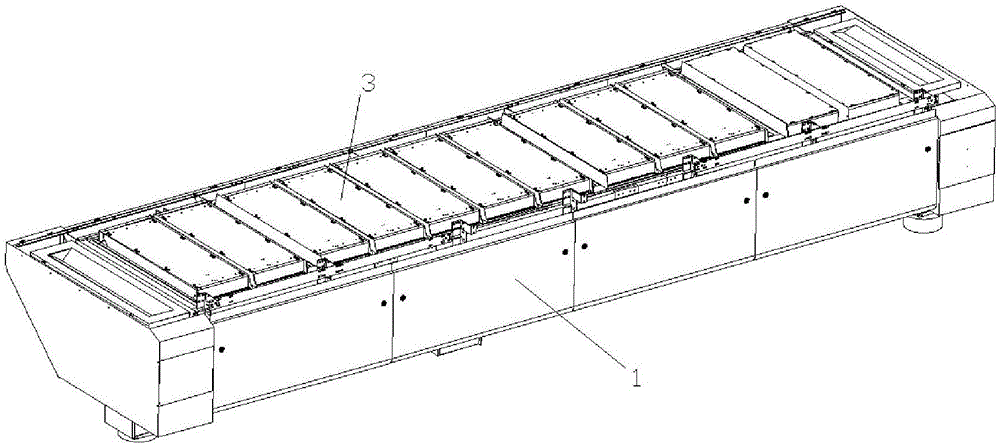

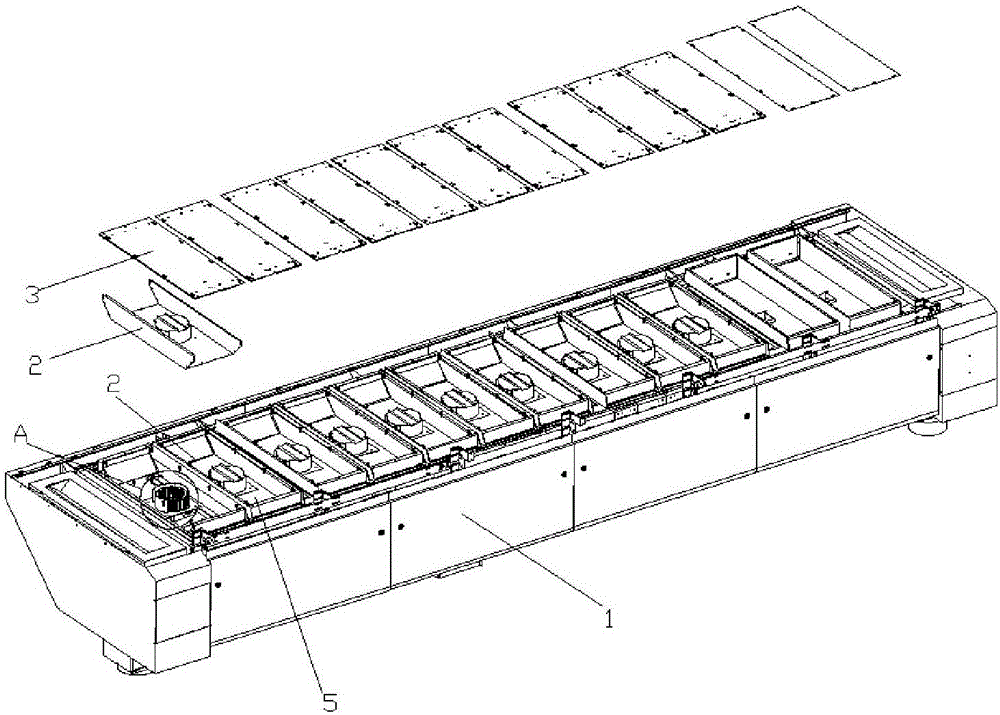

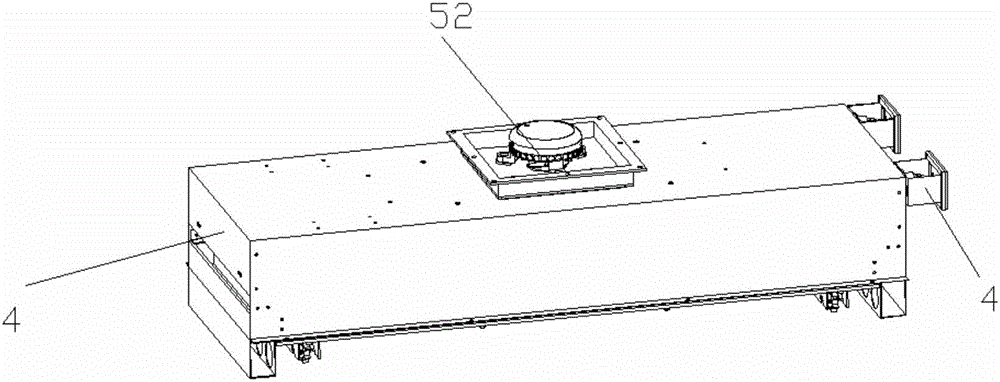

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a heating furnace that is easy to clean and maintain and has high energy efficiency includes a hearth 1 with the same structure at the feed end and the discharge end. The upper plane of the hearth 1 is provided with a plurality of heating chambers 2 at intervals, and each heating chamber 2 The upper end of each is covered with a partition plate 3 that can be slid to open or slid to lock, and the bottom of the heating furnace chamber 2 is provided with a heating tube assembly 4 that can be pulled out horizontally from the bottom of the heating furnace chamber 2 or pushed into and clamped horizontally. A radiator plate 5 is used to separate the bottom of the furnace chamber 2 from the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com