Hot air non-woven fabrics capable of fast and efficiently guiding flow and inhibiting bacteria and production method thereof

A hot air non-woven fabric, fast technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problem that the performance of hot air non-woven fabric needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

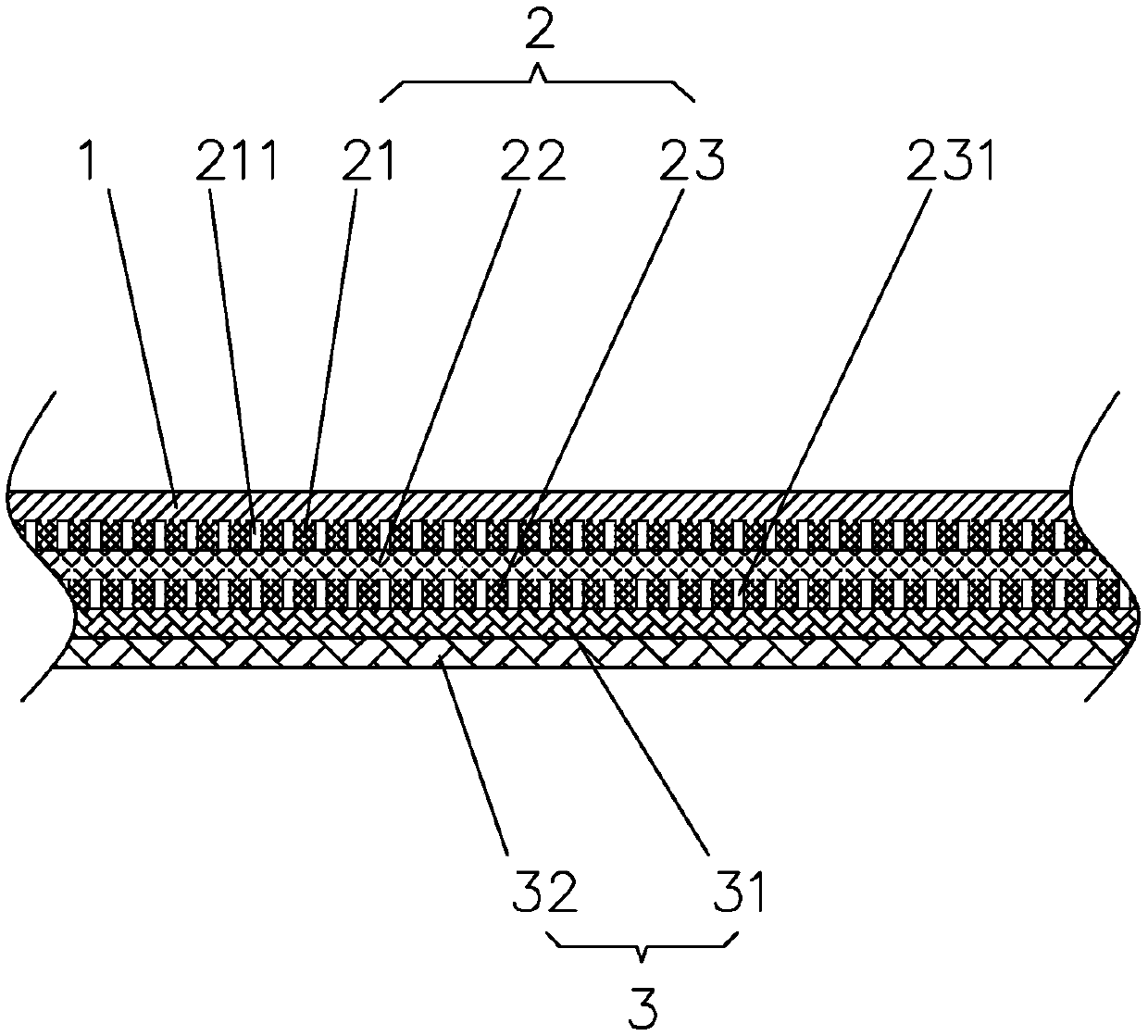

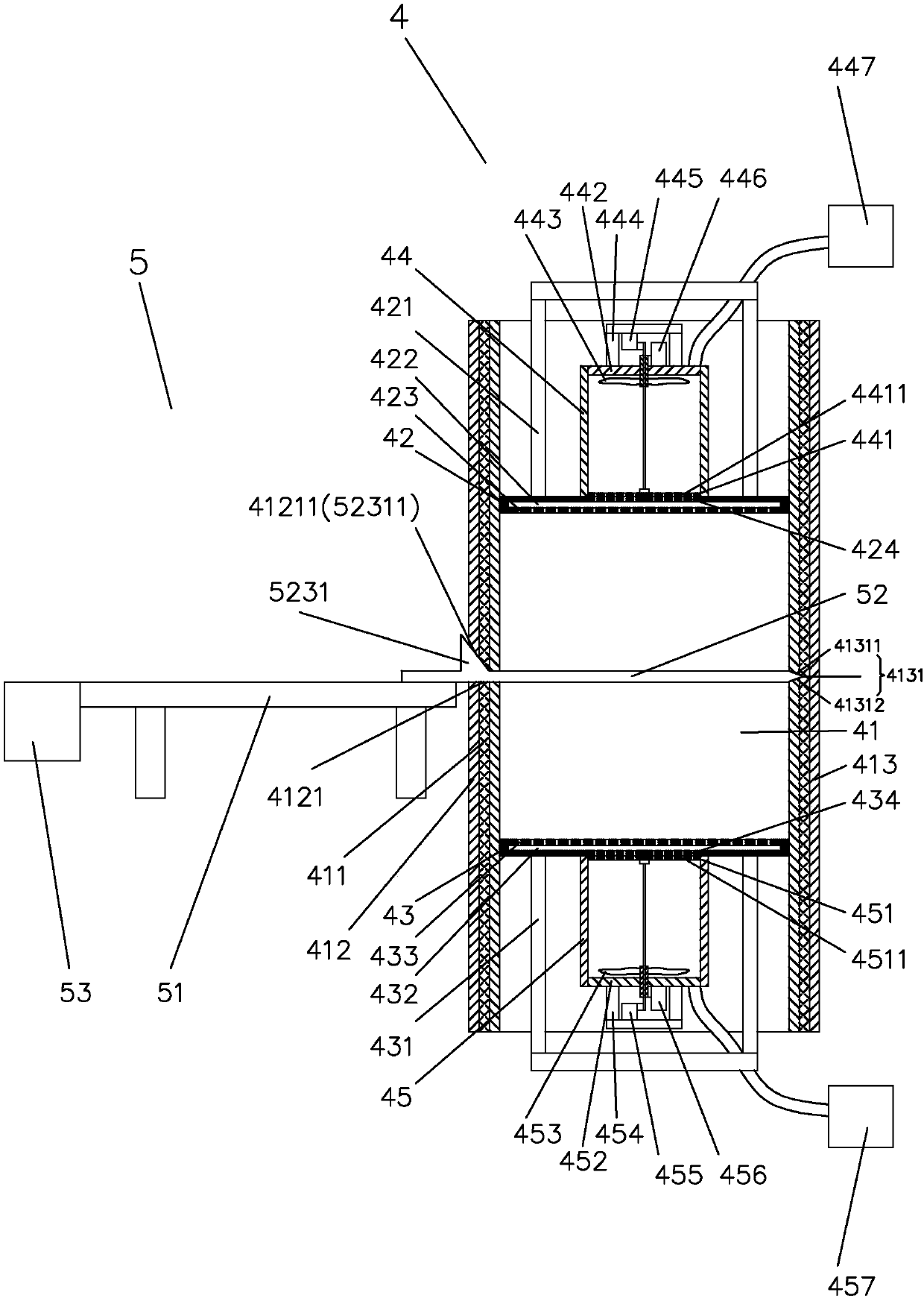

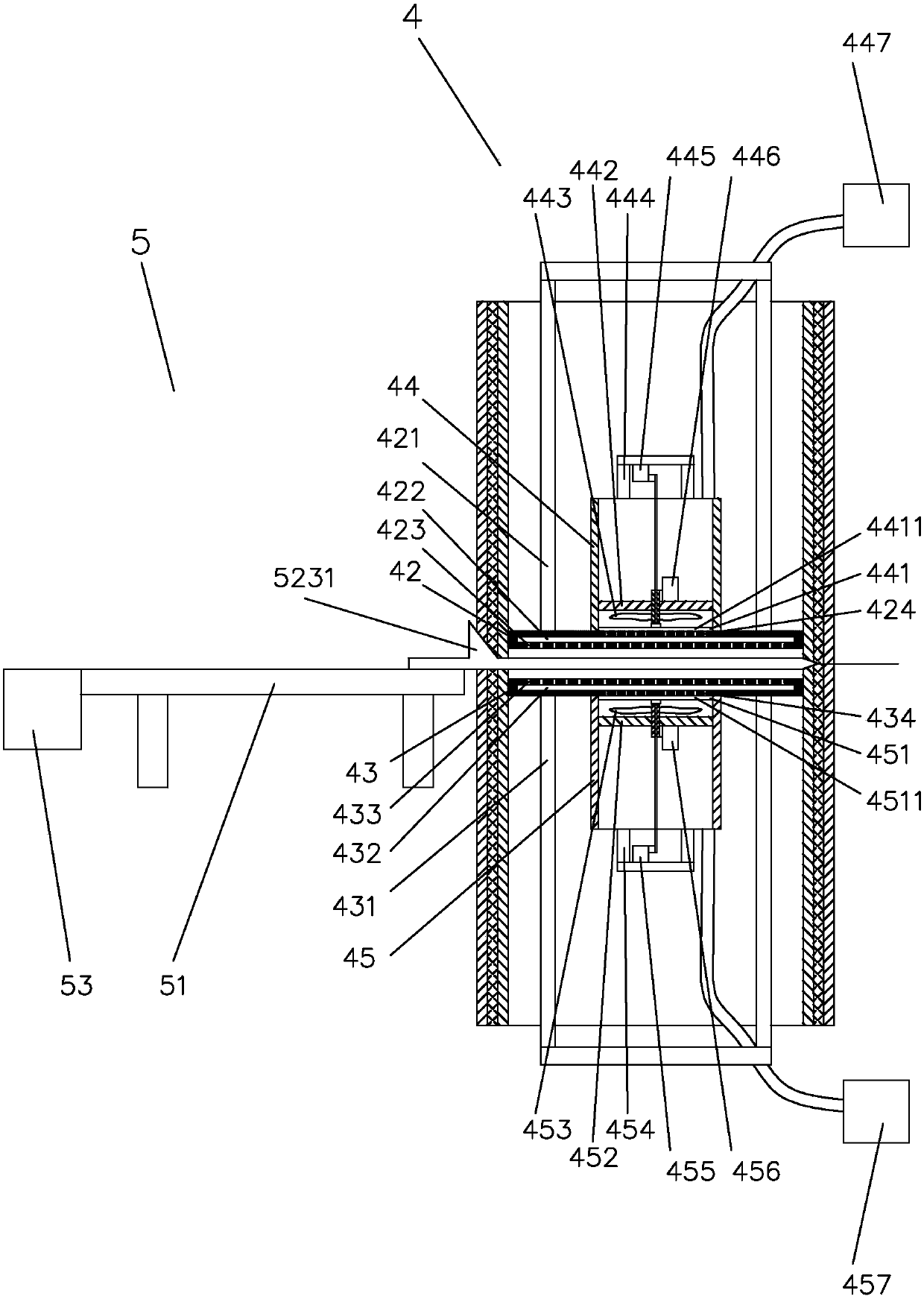

[0048] A kind of high-efficiency rapid diversion of the present invention can antibacterial hot-air non-woven fabric, such as Figure 1-5As shown, it includes an upper fiber layer 1, a fiber composite layer 2 and a lower fiber layer 3 that are sequentially composited together from top to bottom, and the fiber composite layer 2 includes an upper latex layer 21 and a mixed fiber layer that are sequentially composited together from top to bottom. 22 and the lower latex layer 23; the upper fiber layer 1 is made of thermoplastic synthetic fibers, and the lower fiber layer 3 includes a dense fiber layer 31 in the upper layer and a sparse fiber layer 32 in the lower layer, the sparse fiber layer 32 is made of thermoplastic synthetic fibers, and the dense fiber layer The layer 31 is made of thermoplastic synthetic fibers denser than the spar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com