A concrete uniaxial tensile test fixture and test method

A technology of uniaxial tension and test fixture, which is applied in the preparation of test samples, the use of stable tension/compression to test the strength of materials, sampling and other directions, which can solve the failure of concrete uniaxial tension test and the creep of the contact part of the fixture Destruction, loss of test accuracy and other problems, to achieve the effect of improving reliability and stability, reducing cracks and creep, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

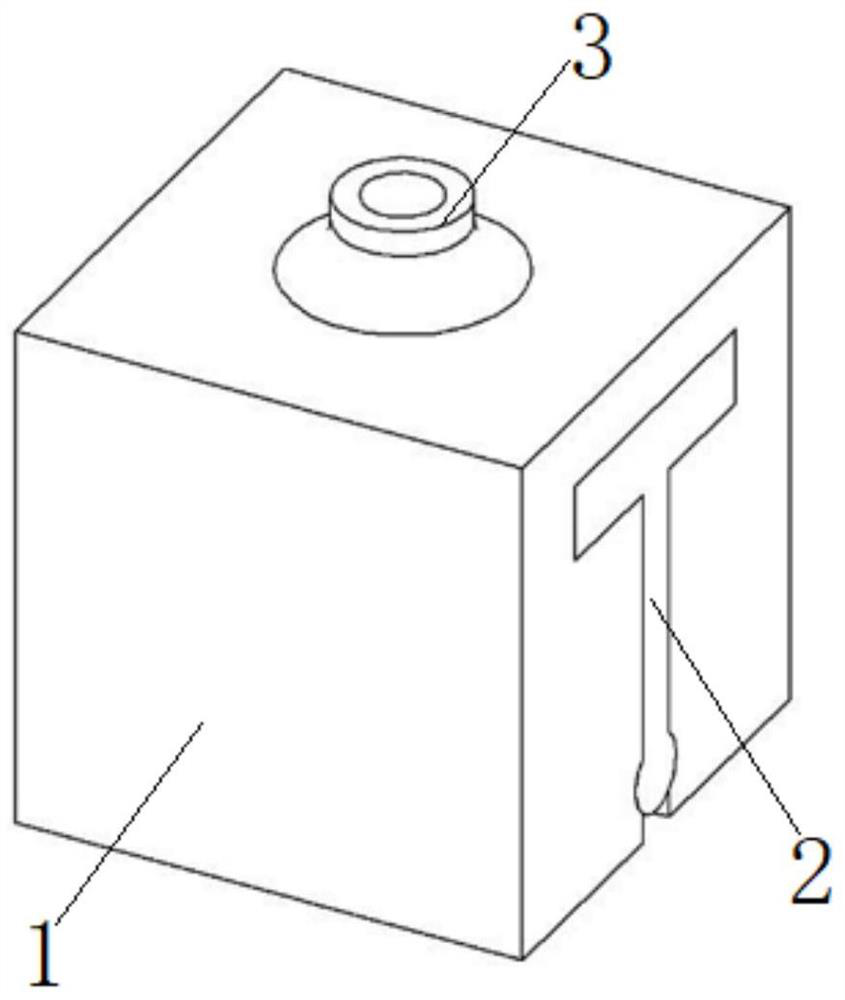

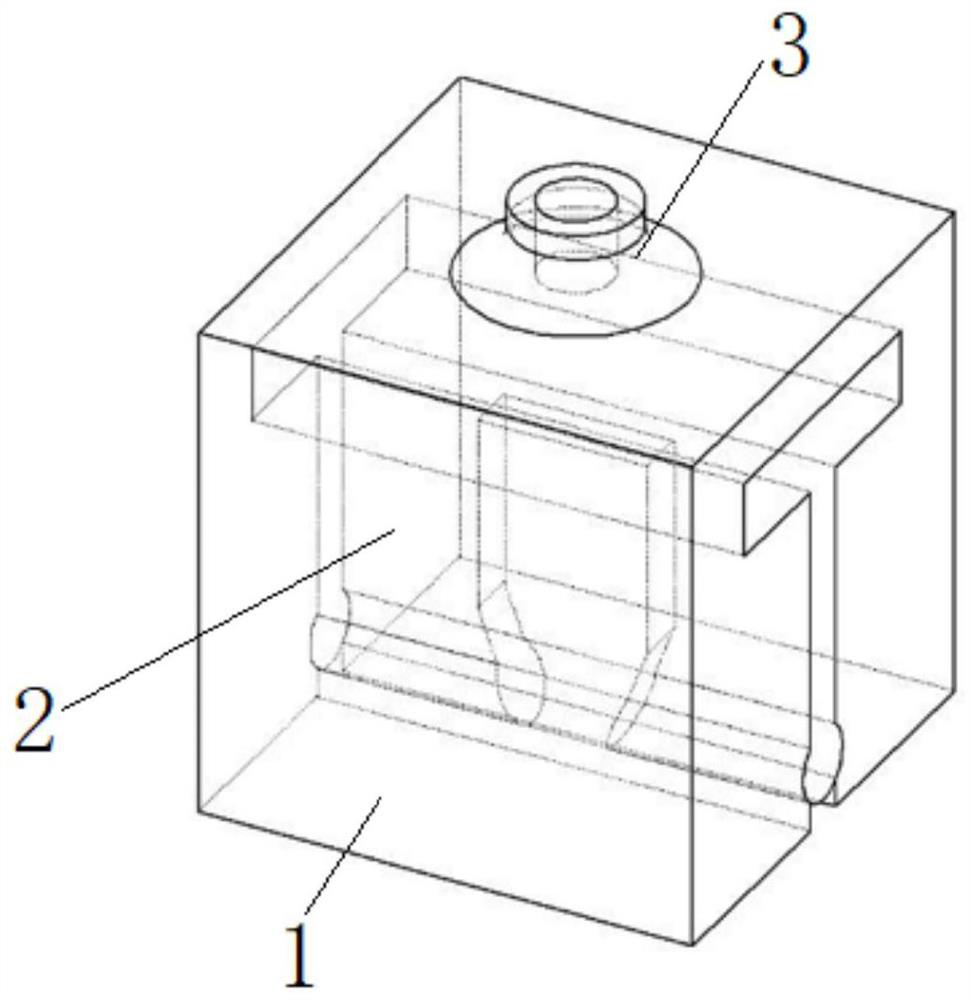

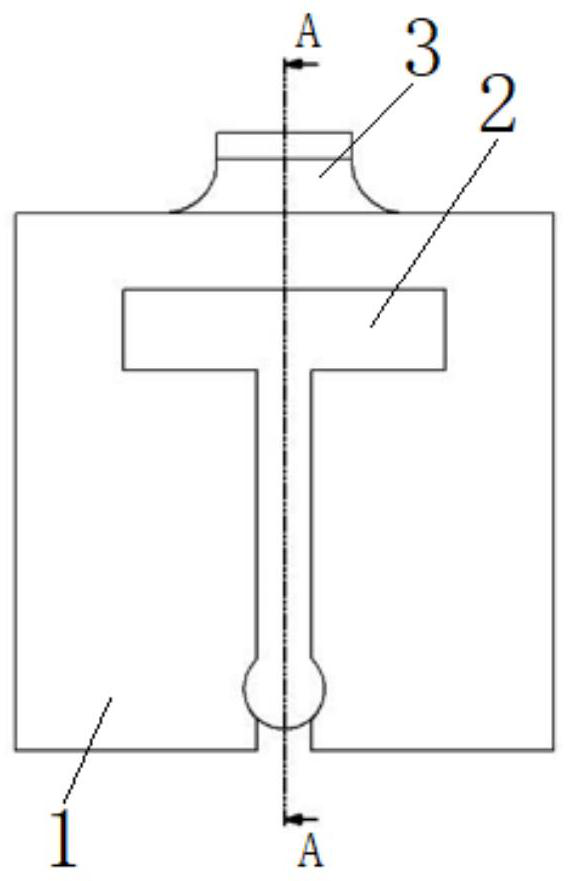

[0052] as attached Figure 1-7 , as shown in 10-14, the present invention provides a concrete uniaxial tensile test fixture, comprising two clamp bodies 1 with the same structure, the two clamp bodies 1 are respectively arranged at the two ends of the concrete specimen 5, through the clamp body 1 The concrete specimen 5 is fixedly installed on the tensile testing machine; preferably, the tensile testing machine adopts an ordinary hydraulic tensioning machine; a specimen holder 2 is arranged between the clamp body 1 and the concrete specimen 5, and the specimen clamp The holder 2 is horizontally embedded in the clamp body 1; the specimen holder 2 is provided with a specimen installation groove 221, and the clamping end of the concrete specimen 5 is fitted in the specimen installation groove 221, and the concrete specimen 5 The four sides of the clamping end are in close contact with the mounting groove 221 of the test piece, and the two sides of the clamping end of the concrete...

Embodiment 2

[0066] as attached Figure 1-6 , as shown in 8-14, the structure and design ideas of embodiment 2 and embodiment 1 are basically the same, the difference is that the test piece holder 2 in embodiment 2 adopts split design, and the test piece in embodiment 1 The piece holder 2 is divided into two along the vertical plane.

[0067] Specifically, the specimen holder 2 includes a first holder 201 and a second holder 202, and the first holder 201 and the second holder 202 are symmetrically arranged in the T-shaped slot 12; the first holder The holder 201 includes a first transverse clamping plate and a first longitudinal clamping plate, and the first transverse clamping plate is vertically fixed to the first longitudinal clamping plate; the second clamping member 202 includes a second transverse clamping plate and a second The longitudinal clamping plate, the second transverse clamping plate and the second longitudinal clamping plate are vertically fixed; the first transverse clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com