Plate bending resistance detection equipment

A detection equipment and anti-bending technology, which is applied in the direction of applying stable bending force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of destroying equipment and affecting the detection accuracy of workpiece bending resistance, so as to increase the efficiency of detection and enrich The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

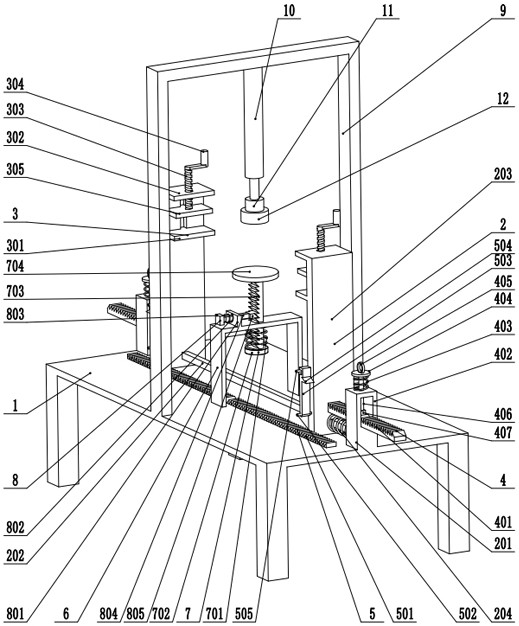

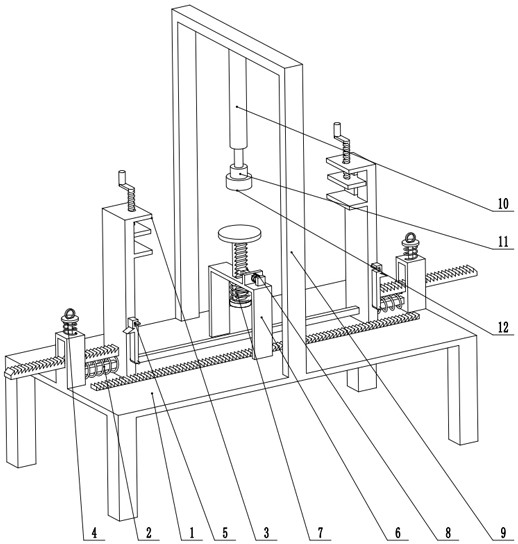

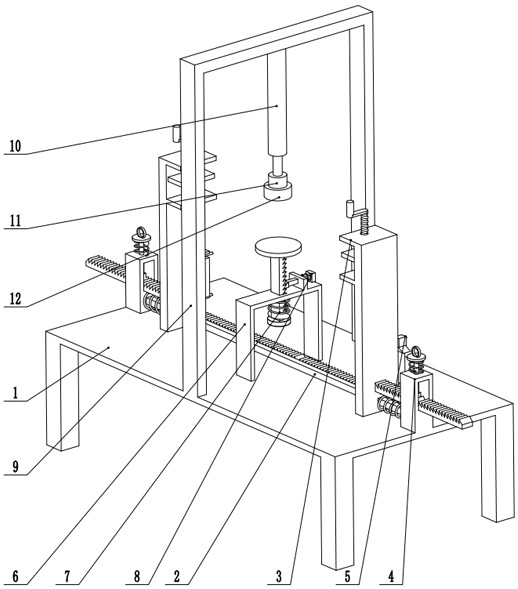

[0026] see Figure 1-7 , a plate body bending resistance testing equipment, including a workbench 1, the workbench 1 is fixedly connected to the moving plate mechanism 2, the moving plate mechanism 2 is provided with a clamping mechanism 3 and a limit moving mechanism 4, the moving plate mechanism 2 The acceleration brake mechanism 5 is fixedly connected, the workbench 1 is fixedly connected with the first installation frame 6, and the first installation frame 6 is provided with a bearing platform mechanism 7 and a one-way limit mechanism 8, and the workbench 1 is fixedly connected with the second installation frame 9, The second installation frame 9 is fixedly connected to the hydraulic cylinder 10 , the hydraulic cylinder 10 is fixedly connected to the pressure sensor 11 , and the pressure sensor 11 is fixedly connected to the pressure head 12 .

[0027] The moving plate mechanism 2 includes a slide bar fixing seat 201 fixed on the workbench 1, the slide bar fixing seat 201 ...

Embodiment 2

[0037] see Figure 1-7 , the other content of this embodiment is the same as that of Embodiment 1, except that: the one-way limit mechanism 8 includes a slide bar placement plate 801 fixed on the first mounting bracket 6, and the slide bar placement plate 801 is far away from the second One side of the block plate 703 is fixedly connected to the fourth spring 802, and the end of the fourth spring 802 away from the second block plate 703 is fixedly connected to the second slider fixing plate 803, and the second slider fixing plate 803 is fixedly connected to the second slider 804 , the second slide bar 804 passes through the slide bar placement plate 801 and is slidably connected with the slide bar placement plate 801 , and the second slide bar 804 is fixedly connected with the second clamping block 805 .

[0038] During the implementation of the present invention, the distance between the moving plate mechanism 2 is first adjusted to a suitable position, and then the plate bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com