Grinding device for processing automobile parts

A technology of auto parts and components, which is applied in the field of auto parts processing, can solve the problems of inconvenient use for users, inconvenient clamping of workpieces, and reduced practicality of grinding devices, so as to achieve convenient grinding operations, high grinding efficiency, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

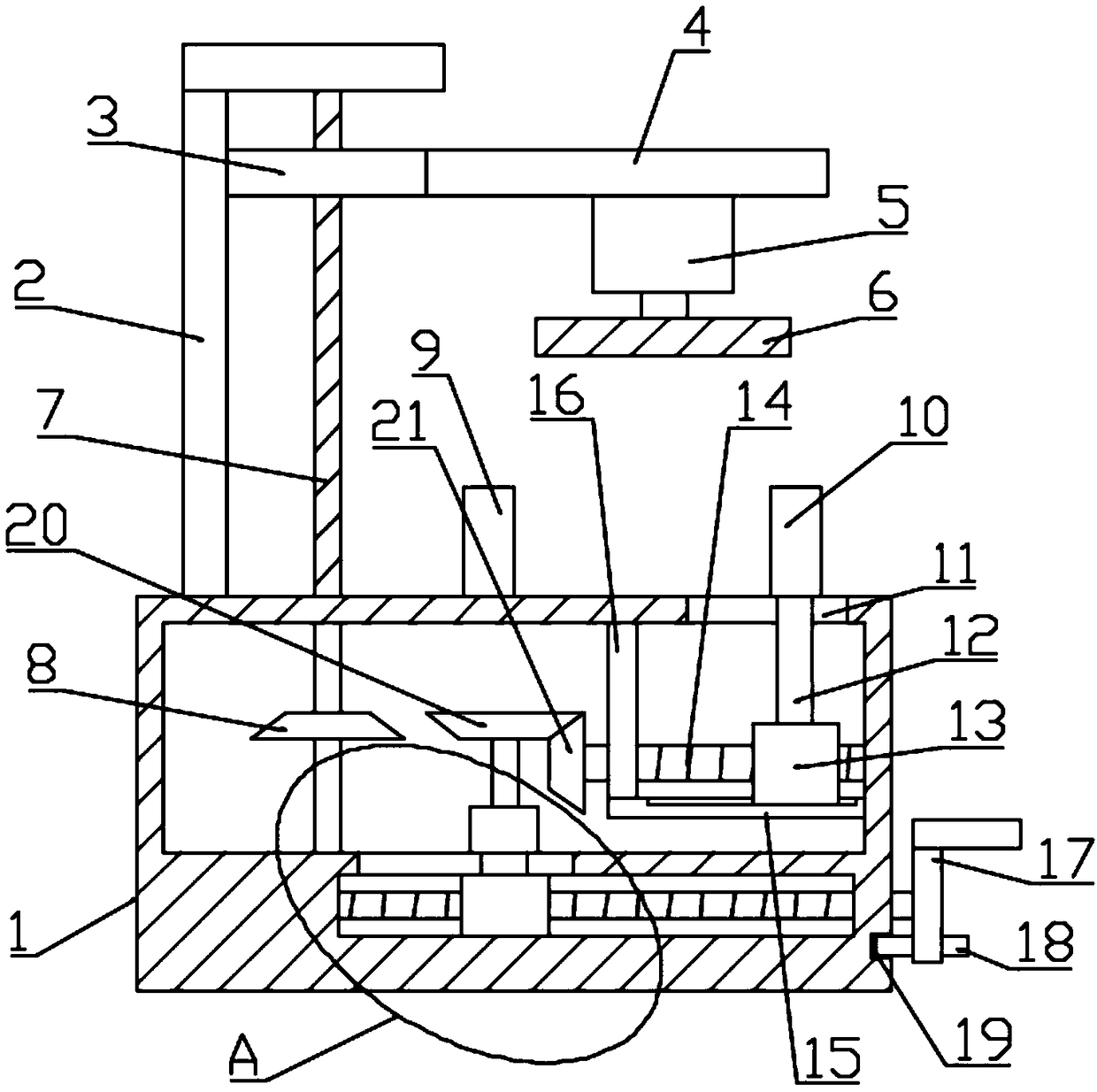

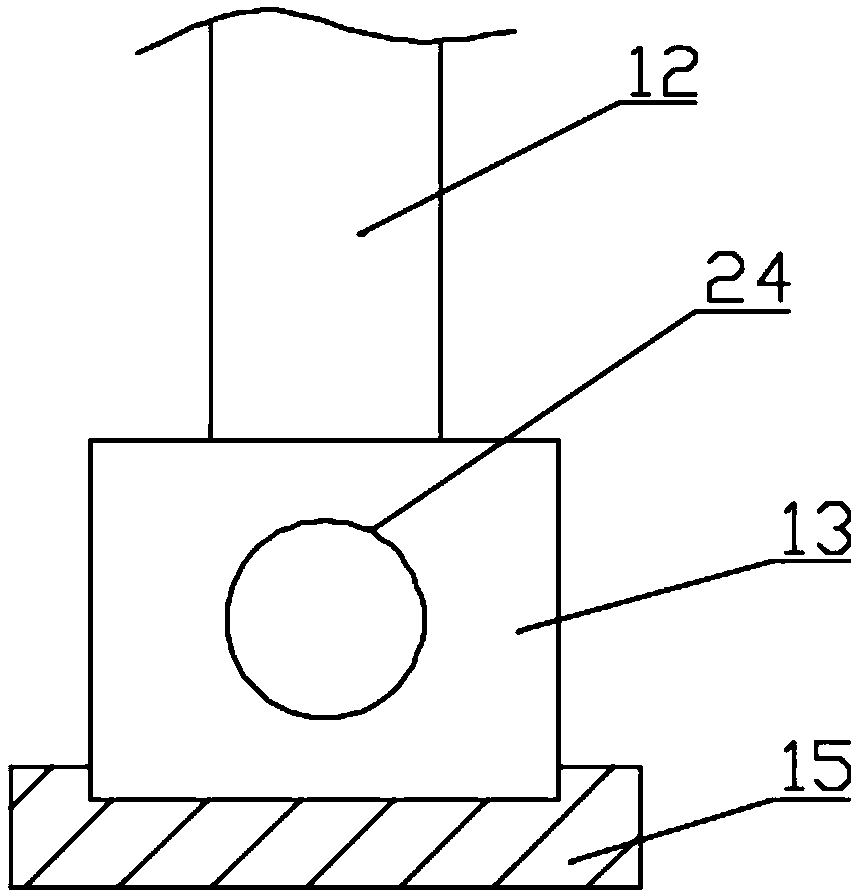

[0022] see figure 1 and figure 2 , in the embodiment of the present invention, a kind of grinding device for automobile parts processing comprises base 1, lifting block 3, grinding motor 5, fixed clamping block 9, movable clamping block 10, moving slider 13, second screw rod 14, drive Motor 25 and grinding assembly, the upper surface of the left end of the base 1 is fixedly equipped with a vertical support column 2, the support column 2 is provided with a first screw 7 for rotation, and the bottom end of the first screw 7 is placed on the base 1, and the lifting block 3 is threadedly installed on the first screw rod 7, further, a transverse bevel gear 8 is fixedly installed on the first screw rod 7 in the inner cavity of the base 1; the lifting block 3 is fixedly installed with a support beam 4, and the grinding assembly is fixedly installed on the lower surface of the end of the support beam 4. The grinding assembly includes a grinding motor 5 and a grinding disc 6 connecte...

Embodiment 2

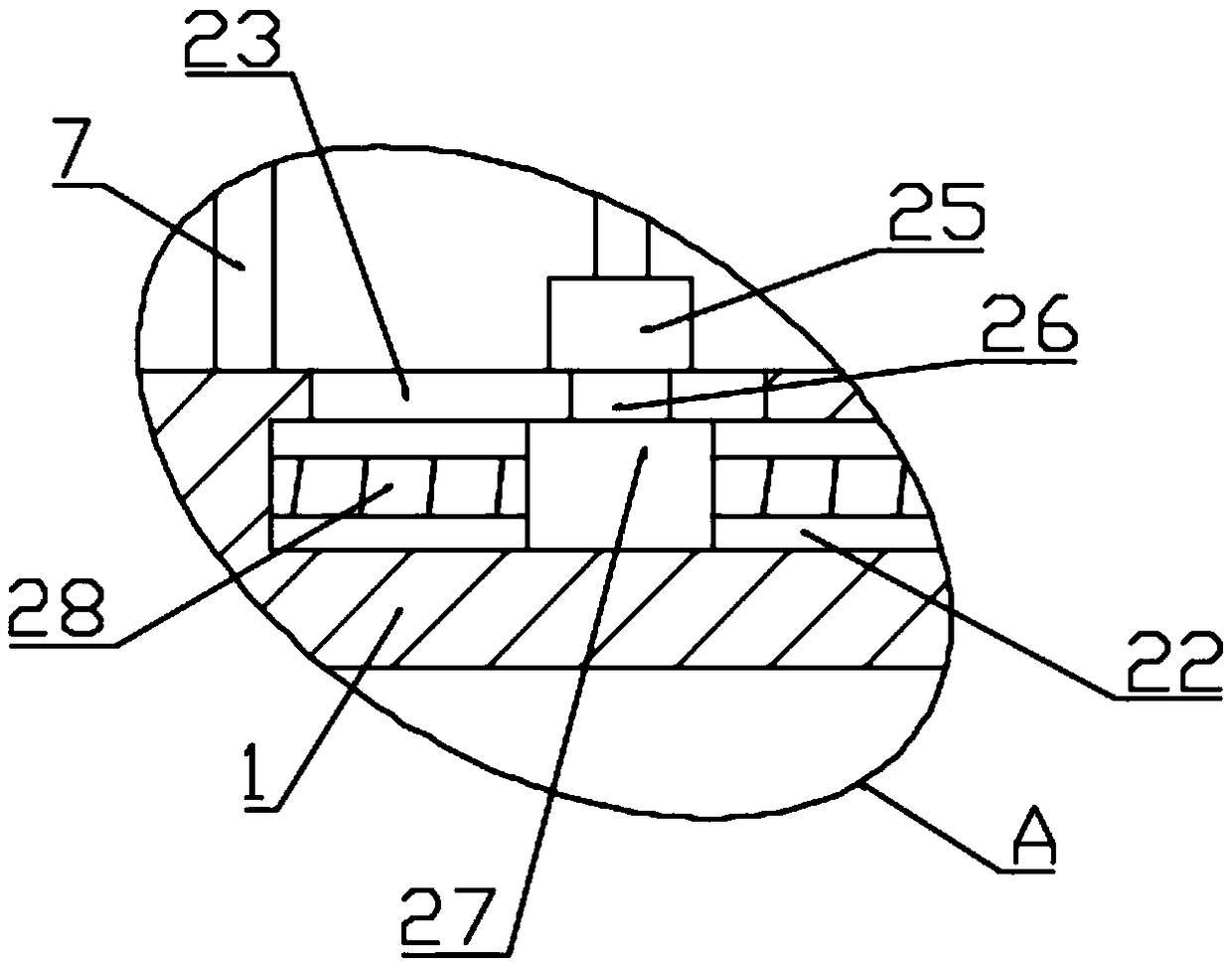

[0028] Unlike Example 1, see figure 1 and image 3, in the embodiment of the present invention, the adjustment mechanism includes a rectangular slider 27 and a third screw 28, wherein the third screw 28 is rotated and installed in the rectangular sliding cavity 22 opened on the bottom plate of the base 1, and the rectangular slider 27 is horizontal Sliding is arranged in the rectangular sliding chamber 22, and the rectangular sliding block 27 is screwed and installed on the third screw mandrel 28. The top plate of the rectangular sliding chamber 22 is provided with a second strip-shaped through hole 23, and the second strip-shaped through-hole 23 Horizontal sliding is provided with a pillar 26 fixedly installed on the rectangular slider 27, wherein the driving mechanism is fixedly installed on the top of the pillar 26, further, the right end of the third screw 28 rotates through the right side plate of the rectangular sliding chamber 22 Set, and place the handle 17 on the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com