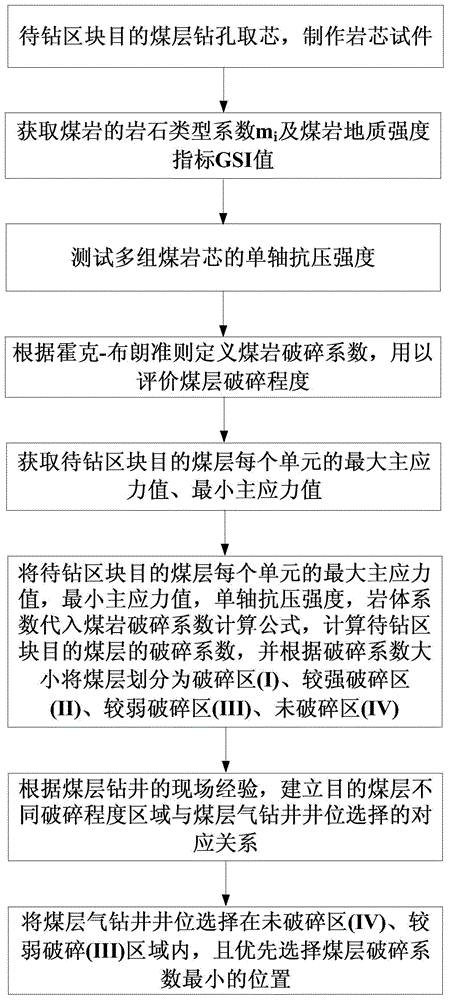

Well drilling position selection method in consideration of coal seam crushing degree

A technology for coal seam and drilling, which is applied in wellbore/well components, earth-moving drilling and production of fluids, etc., to prevent wellbore collapse and reduce drilling risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

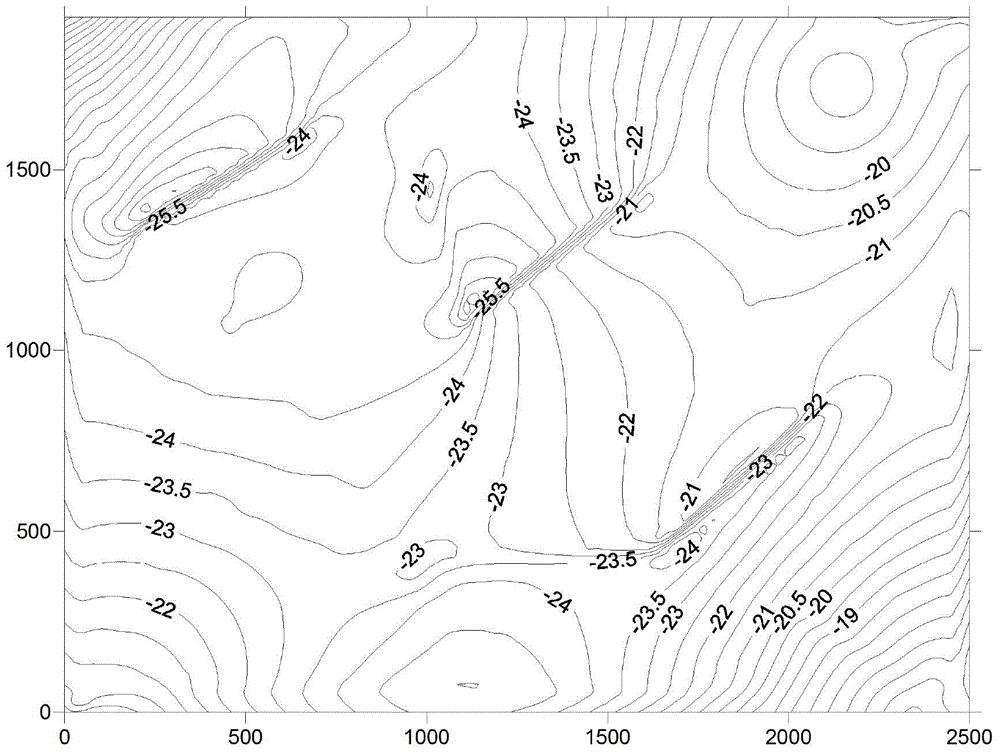

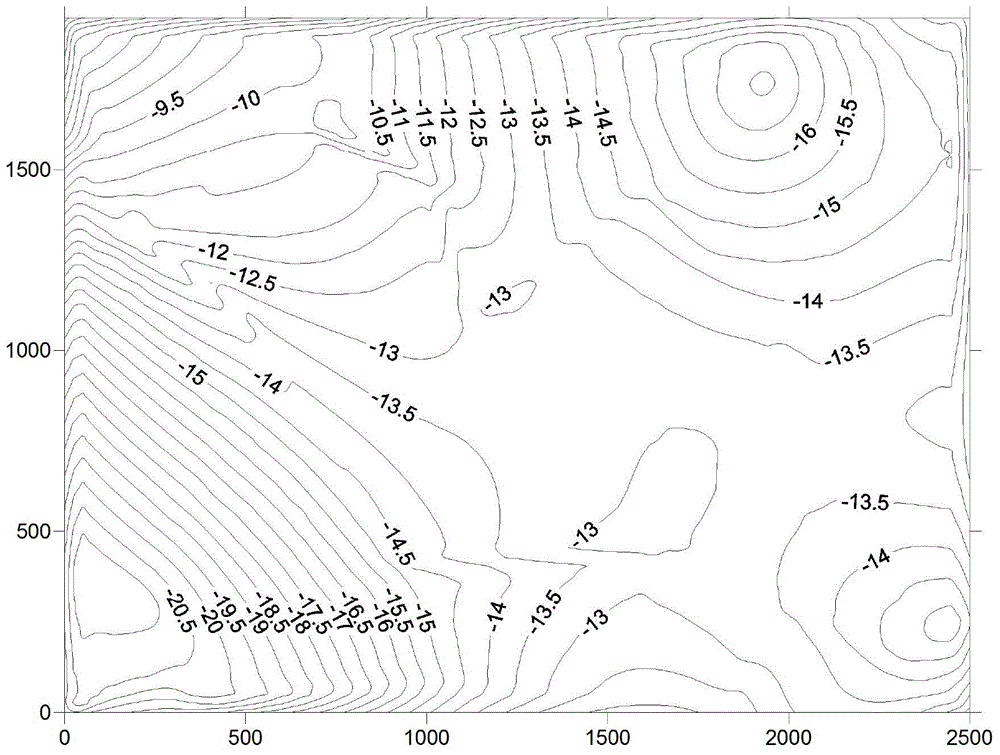

[0063] Taking the selection of coalbed methane drilling well location in a certain block as an example, the method of drilling well location selection considering the degree of coal seam fragmentation is further explained.

[0064] (1), get large piece of rock core from certain coal seam drilling, determine the rock of coal rock by look-up table 1 rock type coefficient (this figure comes from Canada Evert Hoek's monograph " practical rock mass engineering technology " book, the 139th page) Type factor mi=15. With reference to the rock mass geological strength index in Table 2 (this figure comes from the monograph "Practical Rock Mass Engineering Technology" of Canada Evert Hoek, page 145), determine the geological strength index GSI=55 of coal rock;

[0065] (2), carry out experimental sample processing to the massive rock core of coal seam that obtains, make 20 groups of standard cylindrical coal rock core specimens, the height of standard cylindrical coal rock core specimens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com