Establishment method for detecting concrete compressive strength curve by rebound method

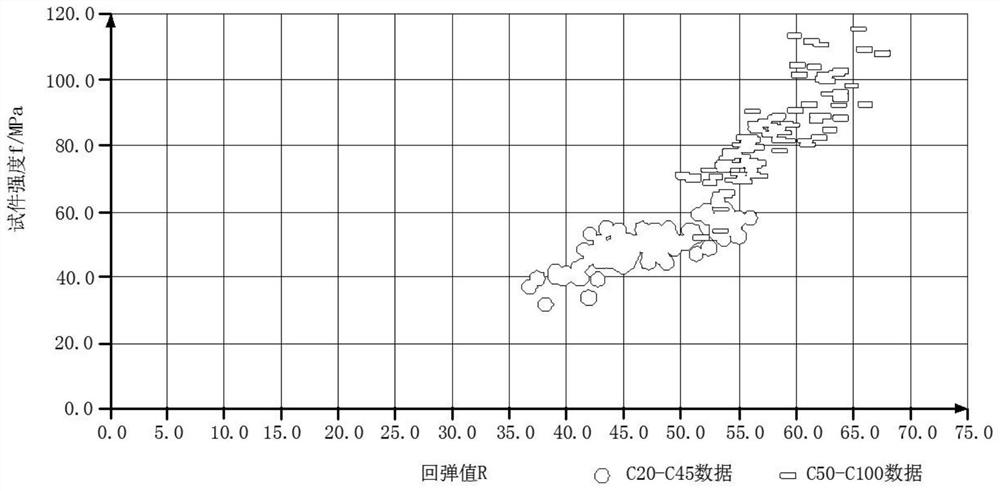

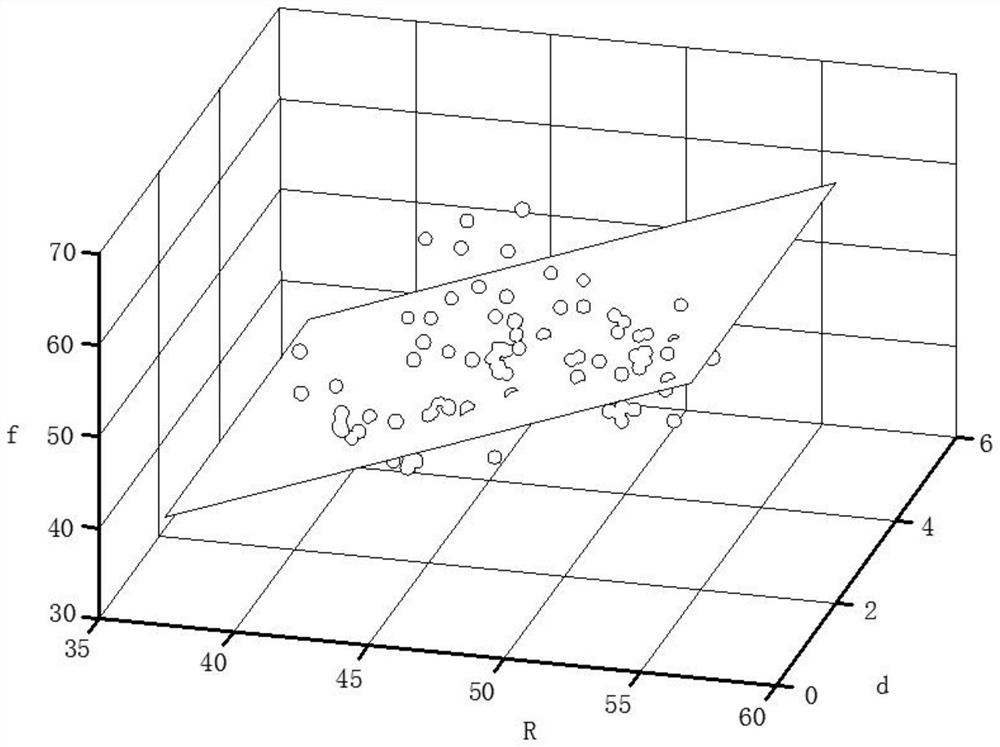

A technology for compressive strength and establishment methods, which is applied in the direction of strength characteristics, using stable tension/pressure to test material strength, testing material hardness, etc., can solve the problems that high-strength rebound instruments cannot be applied to low-strength concrete, and achieve expanded use Effects of range, crossover reduction, presumed convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Before the experiment, the technical test piece parameters should meet:

[0032] (1). The test piece complies with the provisions of the current industry standard "Concrete Test Formwork" JG 237;

[0033] (2). The test age of the specimen is 14d, 28d, 60d;

[0034] (3). After demoulding, the test pieces are stacked in the shape of "product" and placed in a place free from sun and rain for natural maintenance;

[0035] (4). For concrete of the same strength grade, test at least 3 specimens in each age measurement period;

[0036] (5). The nominal kinetic energy of the rebound hammer is 4.5J;

[0037] (6). The concrete strength grade is C20-C100.

[0038] A method for establishing a rebound method to detect concrete compressive strength curves, comprising the following steps:

[0039] S1: Specimen selection: select a standard size cube specimen, the standard size of the specimen is 150mm×150mm×150mm, and the concrete design strength grades are C20, C30, C35, C40, C45,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com