Method for improving strength of cement mixing piles for sand-rich geological high-rise building

A technology for cement mixing piles and high-rise buildings is applied in the field of improving the strength of cement mixing piles to achieve the effects of high pile body strength, safe and reliable engineering quality, and high characteristic value of composite foundation bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The specific operation of the method for improving the strength of the sand-rich geological high-rise building cement mixing pile of the present invention is as follows:

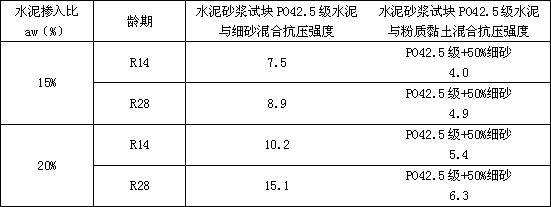

[0029] On-site sampling, the sampling location is located at -3.0m, -5.0m, -6.0m below the natural ground of Building 7 in Block B. After the fine sand and silty clay soil samples are dug out by the hook machine, they are immediately put into plastic bags for delivery. Samples, sampling, numbering, sample delivery, and test block production are fully supervised and supervised in quality. The test block test method refers to the relevant implementation standards and instructions such as "Technical Regulations for Soft Soil Foundation Deep Stirring Method Reinforcement Method" YBJ225-91, "Soil Engineering Test Regulations" SL237-1999 and GB / T50081-2002.CCS03:2007. In the laboratory, several cement-soil test blocks with different cement mixing ratios and different ages were carried out, and Po42.5 grade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com