Detection device and detection method for sleeve grouting quality

A sleeve grouting and detection device technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, preparation of test samples, etc., can solve the problem that the fullness of sleeve grouting cannot be accurately detected, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

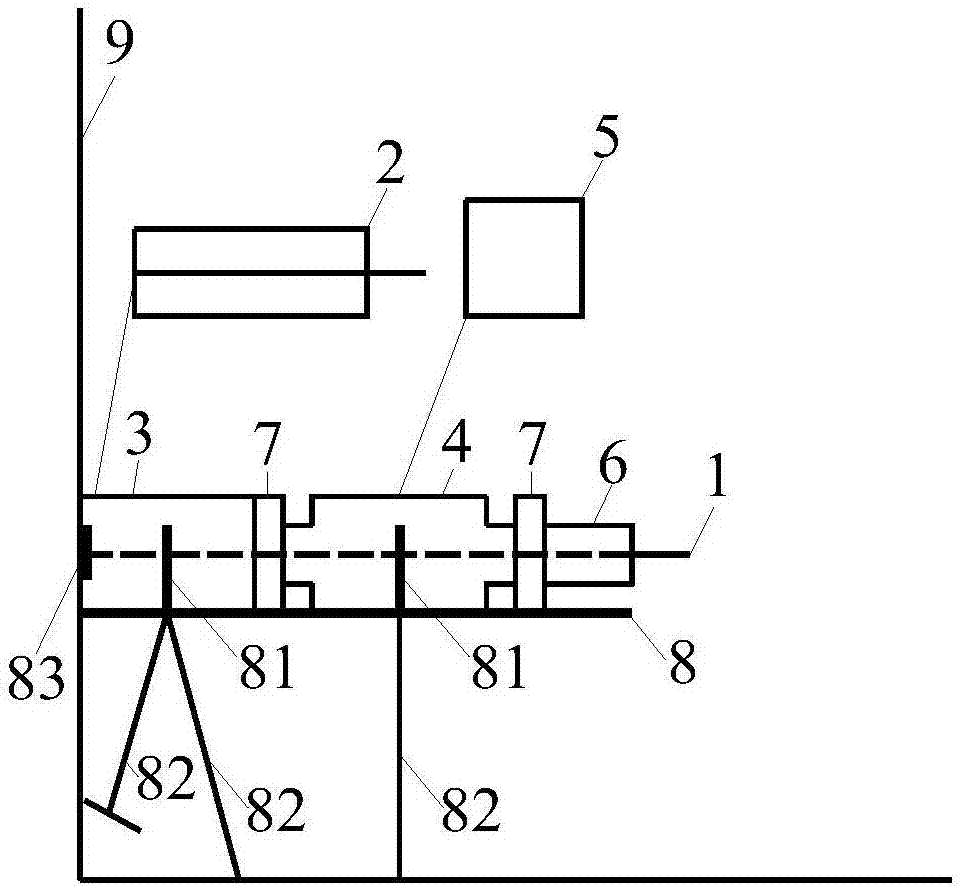

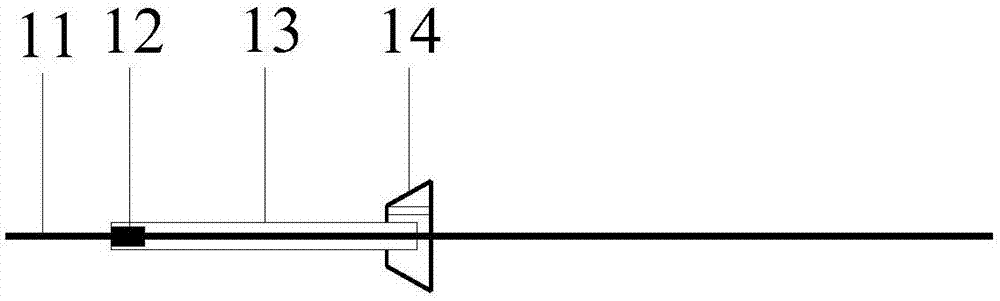

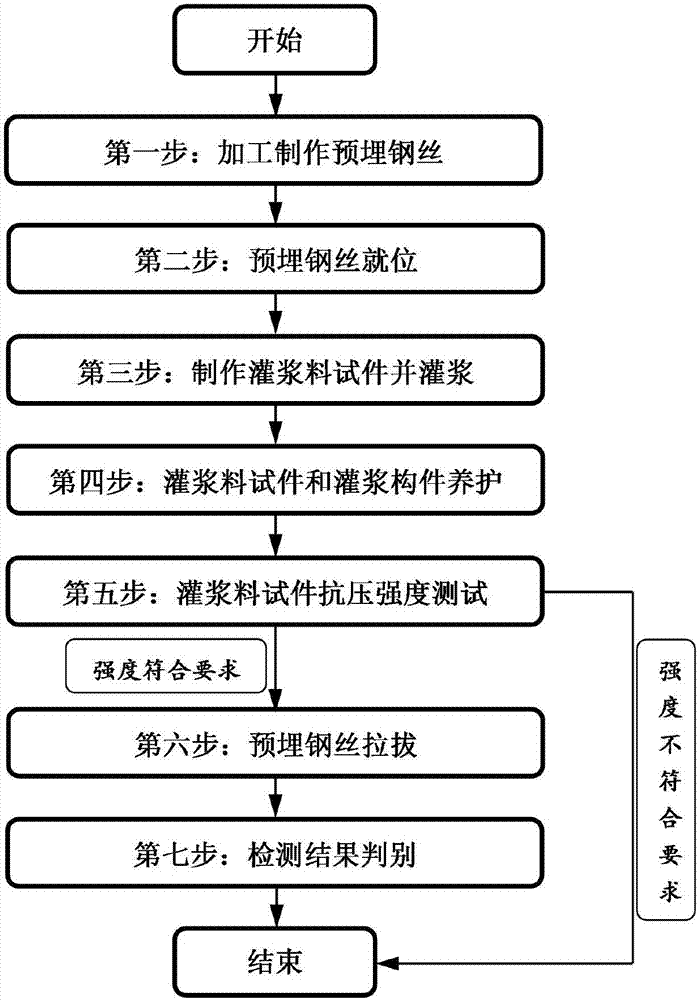

Method used

Image

Examples

Embodiment

[0040] For a prefabricated shear wall, the concrete strength grade is C40, the steel reinforcement strength grade is HRB400, the reinforcement diameter is 25mm, and the wall thickness is 200mm. The sleeves are arranged in a single row in the center, the distance between the centers of the sleeves along the length of the wall is 100mm, and there are 6 sleeves arranged on the wall. The sleeve adopts GTZQ4-25 model (suitable for 25mm steel bar diameter), and the grouting material matched with the sleeve is used. The mass ratio of water and grouting material is 0.14 when mixing. Each sleeve is grouted using a separate grouting test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com