Chemical improving method using soft rock weathered material as high-speed railway subgrade filler

A high-speed railway and subgrade filling technology, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as waste, and achieve the effects of environmental protection, good economy, and reduction of dregs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

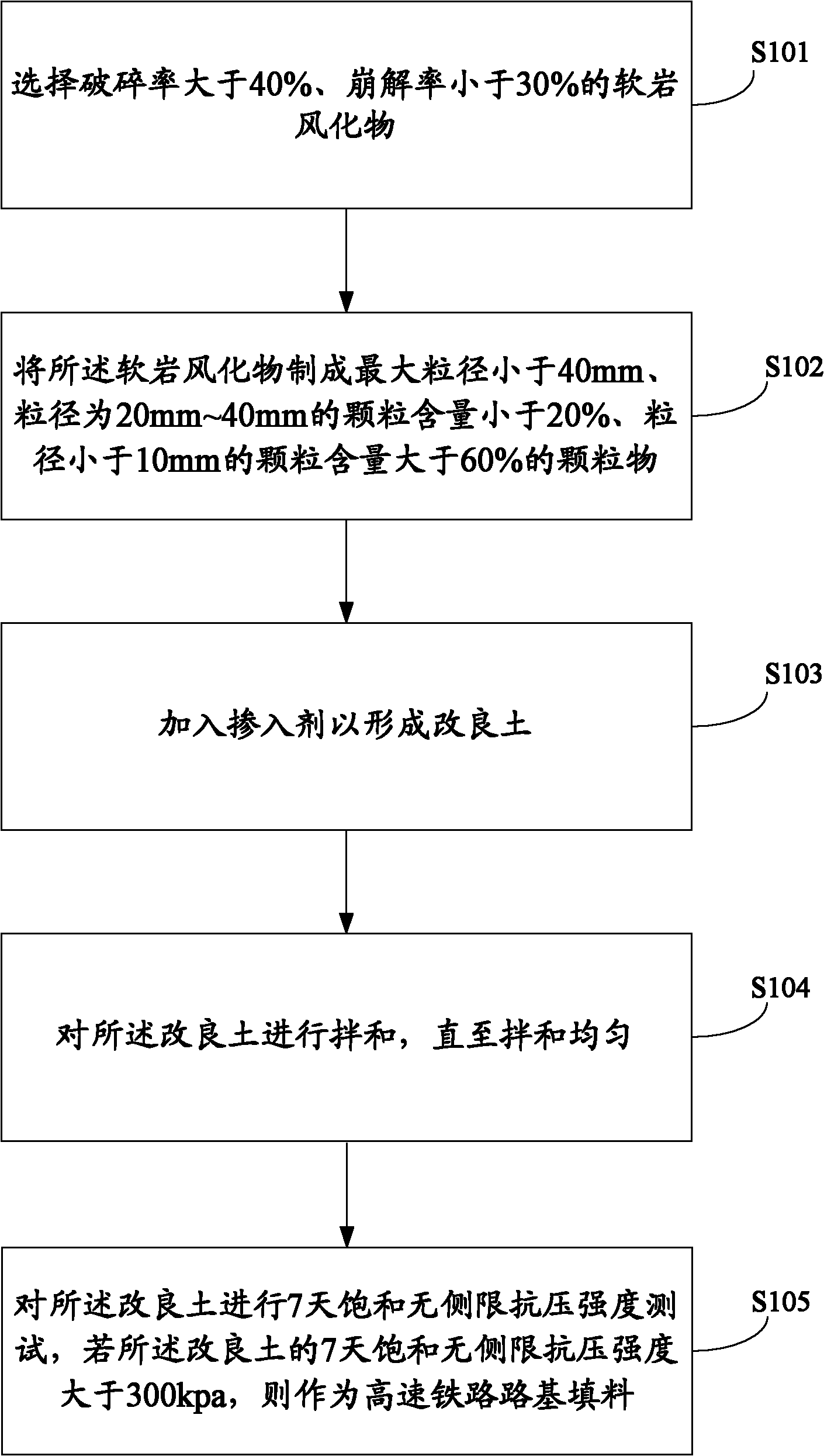

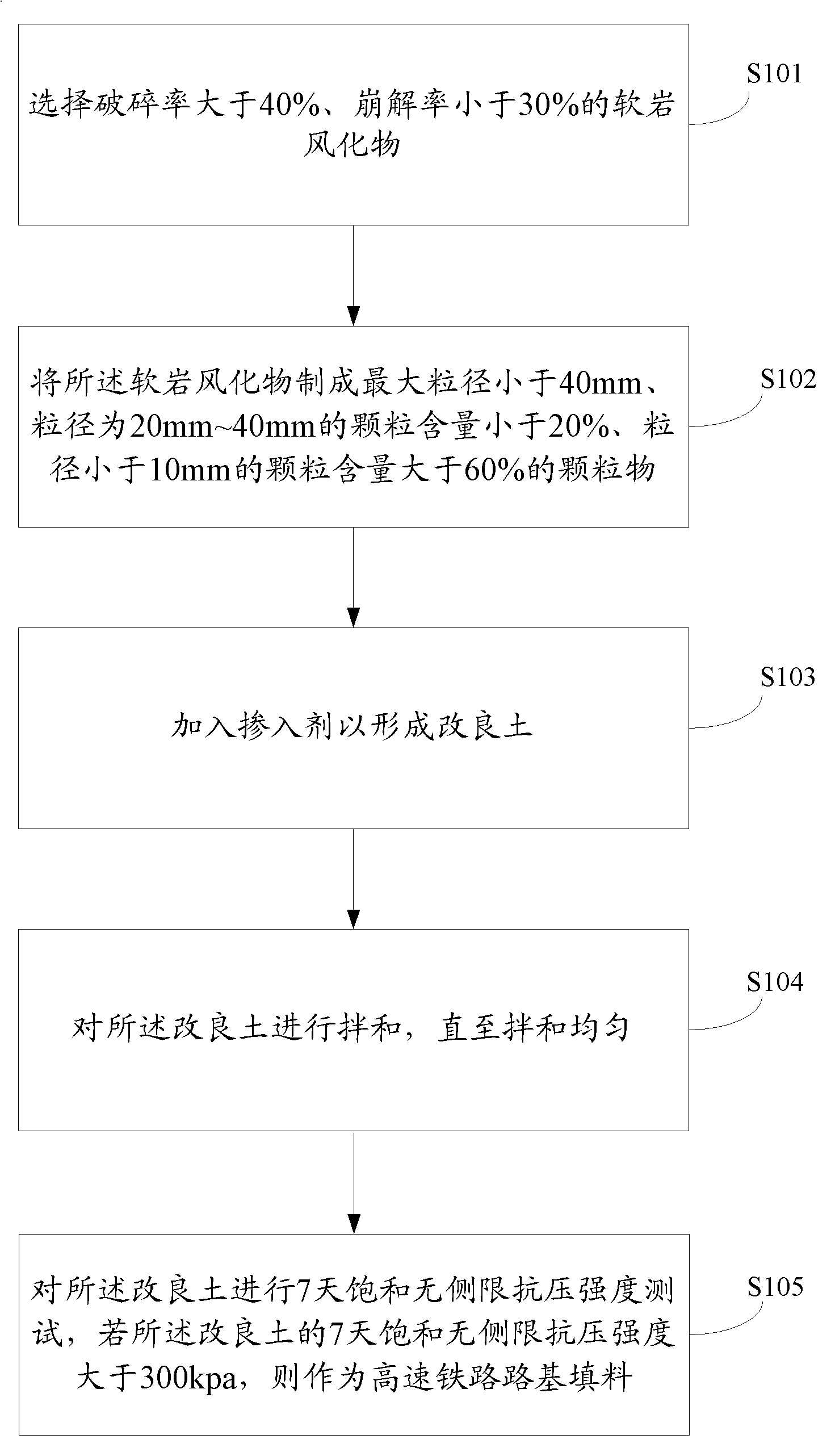

[0019] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a method for chemical improvement of weathered soft rock as filler for high-speed railway roadbeds. The weathered soft rocks are improved to meet the standards for roadbed fillers for high-speed railways, thereby reducing engineering costs and reducing Abandon ballast, protect the environment, and achieve good economic, technological, environmental and social benefits.

[0020] The technical solutions of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, the chemical improvement method of the weathered soft rock of the present embodiment as high-speed railway embankment filler comprises the following steps:

[0021] Step S101: Select soft rock weathered objects with a breakag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com