Method used for calculating rock damaged degree under explosion effects based on nuclear magnetic resonance

A technology of nuclear magnetic resonance and damage degree, which is applied in the analysis of nuclear magnetic resonance, material analysis through resonance, and analysis of solids using sound waves/ultrasonic waves/infrasonic waves. It can solve problems such as lack of equivalent energy and lack of theoretical support for blasting operations. To achieve the effect that is conducive to analysis and parameter selection, reliable data and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

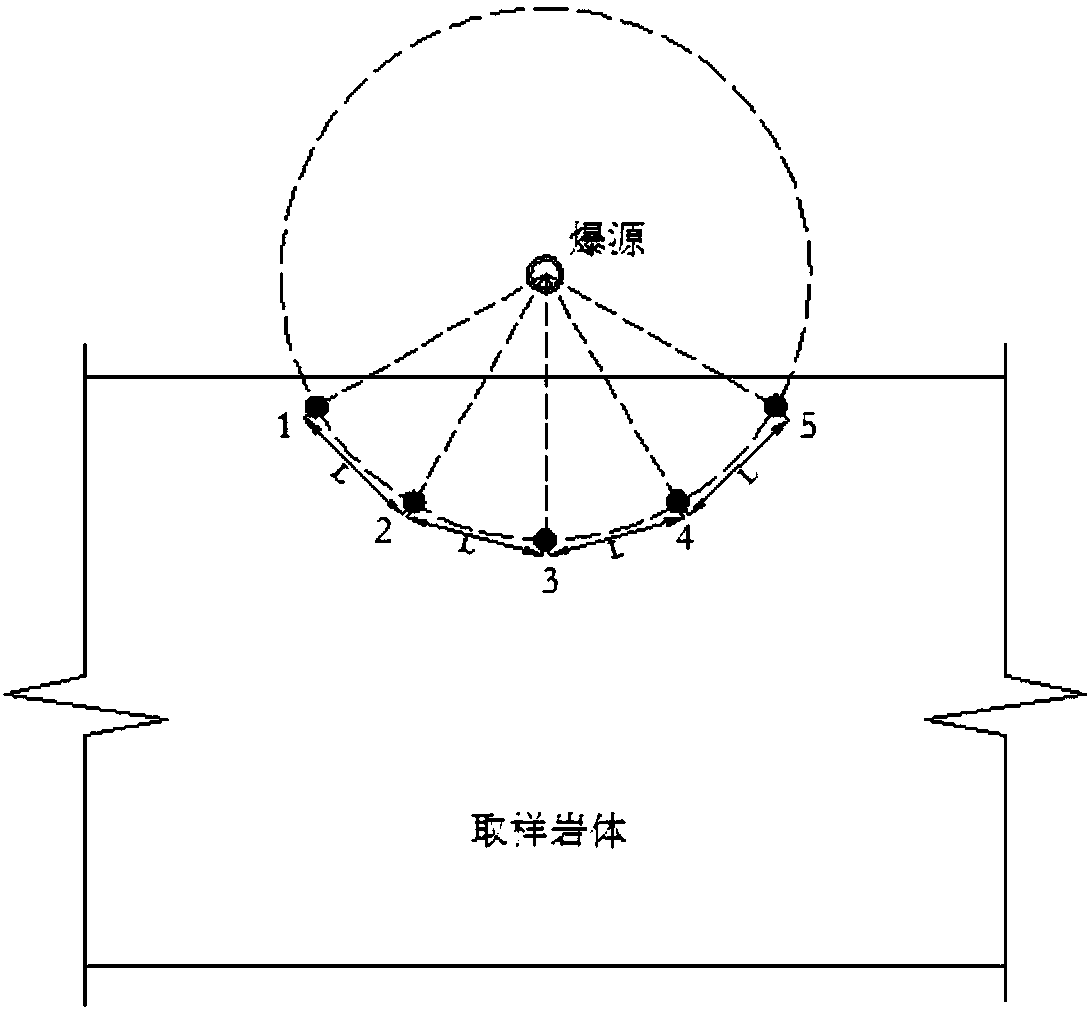

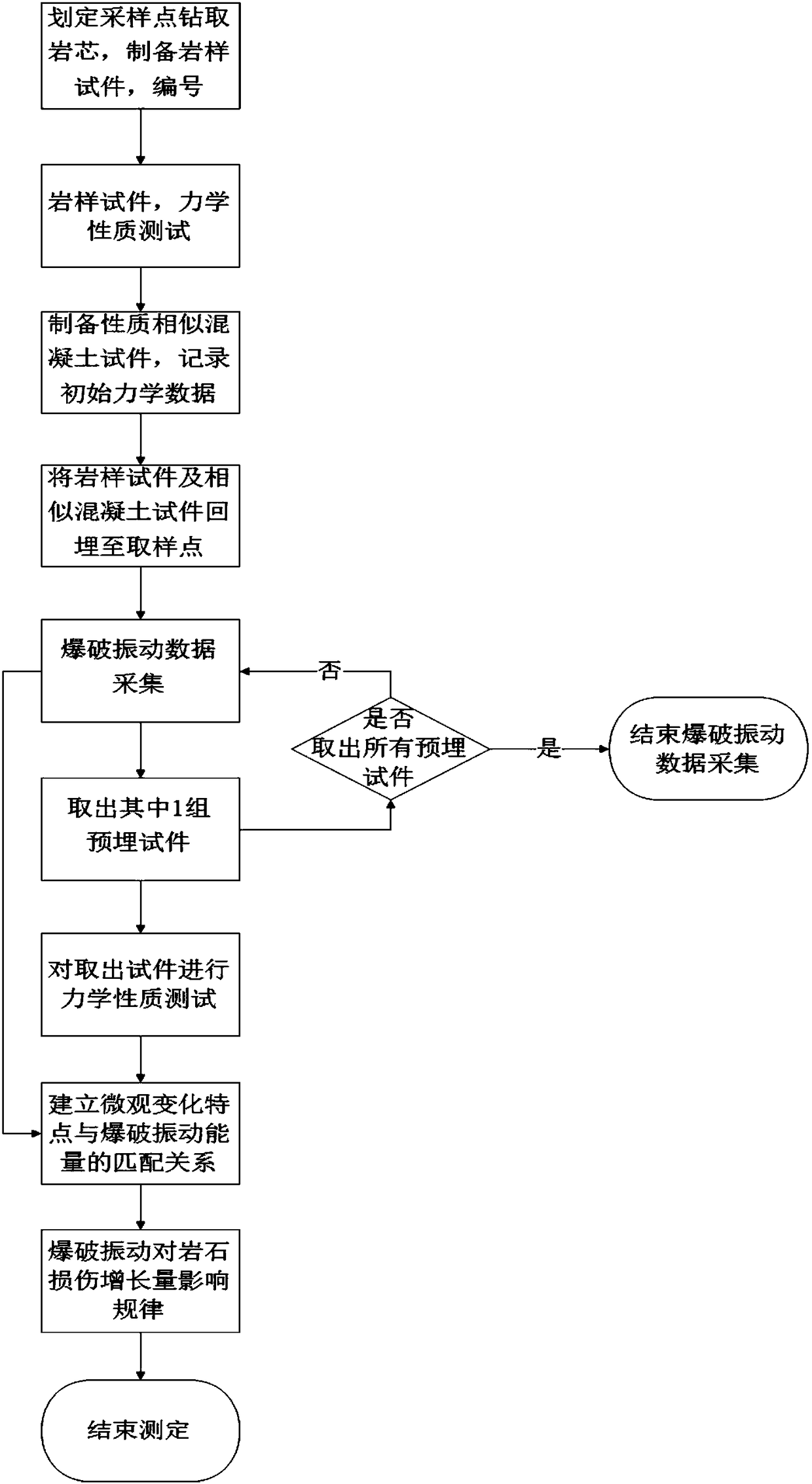

[0040] With the explosion source as the center of the granite to be tested, 6 rock sample collection points are selected at equal intervals, and the diameter is 60±2mm, the length is 200±20mm, and the macroscopic width of the crack is not more than 0.5mm, and the crack depth is less than 2% of the diameter. 3 rock samples, marked. According to the test requirements, the rock samples are processed to prepare rock specimens that meet the test requirements.

[0041] The mechanical properties of the prepared granite specimens were tested and analyzed, and the specific steps were as follows:

[0042](1) Use RSM-SY6 Pile Acoustic Detector to conduct initial acoustic wave detection on rock specimens, and record the longitudinal wave velocity v of rock specimens prepared at each sampling point in turn p ;

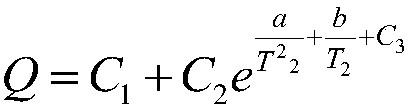

[0043] (2) After performing vacuum saturation treatment on the rock specimen, the MacroMR nuclear magnetic resonance instrument is used to conduct nuclear magnetic resonance test...

Embodiment 2

[0056] At the phyllite to be tested, take the explosion source as the center of the circle and select 5 rock sample collection points at equal intervals, and drill a diameter of 60±2mm and a length of 180±20mm, satisfying the requirement that the macroscopic width of the crack does not exceed 0.5mm, and the depth of the crack is smaller than the diameter. 3 samples of 2% rock, marked. According to the test requirements, the rock samples are processed to prepare rock specimens that meet the test requirements.

[0057] The mechanical properties of the prepared phyllite specimens were tested and analyzed, and the specific steps were as follows:

[0058] (1) Use RSM-SY6 Pile Acoustic Detector to conduct initial acoustic wave detection on rock specimens, and record the longitudinal wave velocity v of rock specimens prepared at each sampling point in turn p ;

[0059] (2) After performing vacuum saturation treatment on the rock specimen, the MacroMR nuclear magnetic resonance inst...

Embodiment 3

[0072] With the explosion source as the center of the magnetite quartzite to be tested, 5 rock sample collection points are selected at equal intervals, and the diameter is 60±2mm, the length is 200±20mm, and the macroscopic width of the crack is not more than 0.5mm, and the crack depth is smaller than the diameter. 3 rock samples of 2% are marked. According to the test requirements, the rock samples are processed to prepare rock specimens that meet the test requirements.

[0073] The mechanical properties of the prepared magnetite quartzite specimens were tested and analyzed, and the specific steps were as follows:

[0074] (1) Use RSM-SY6 Pile Acoustic Detector to conduct initial acoustic wave detection on rock specimens, and record the longitudinal wave velocity v of rock specimens prepared at each sampling point in turn p ;

[0075] (2) After performing vacuum saturation treatment on the rock specimen, the MacroMR nuclear magnetic resonance instrument is used to conduct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com