Cement-stabilized coral reef sand construction process

A technology of cement stabilization and construction technology, applied in roads, road repairs, roads, etc., can solve the problem of high cost and achieve the effect of saving engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

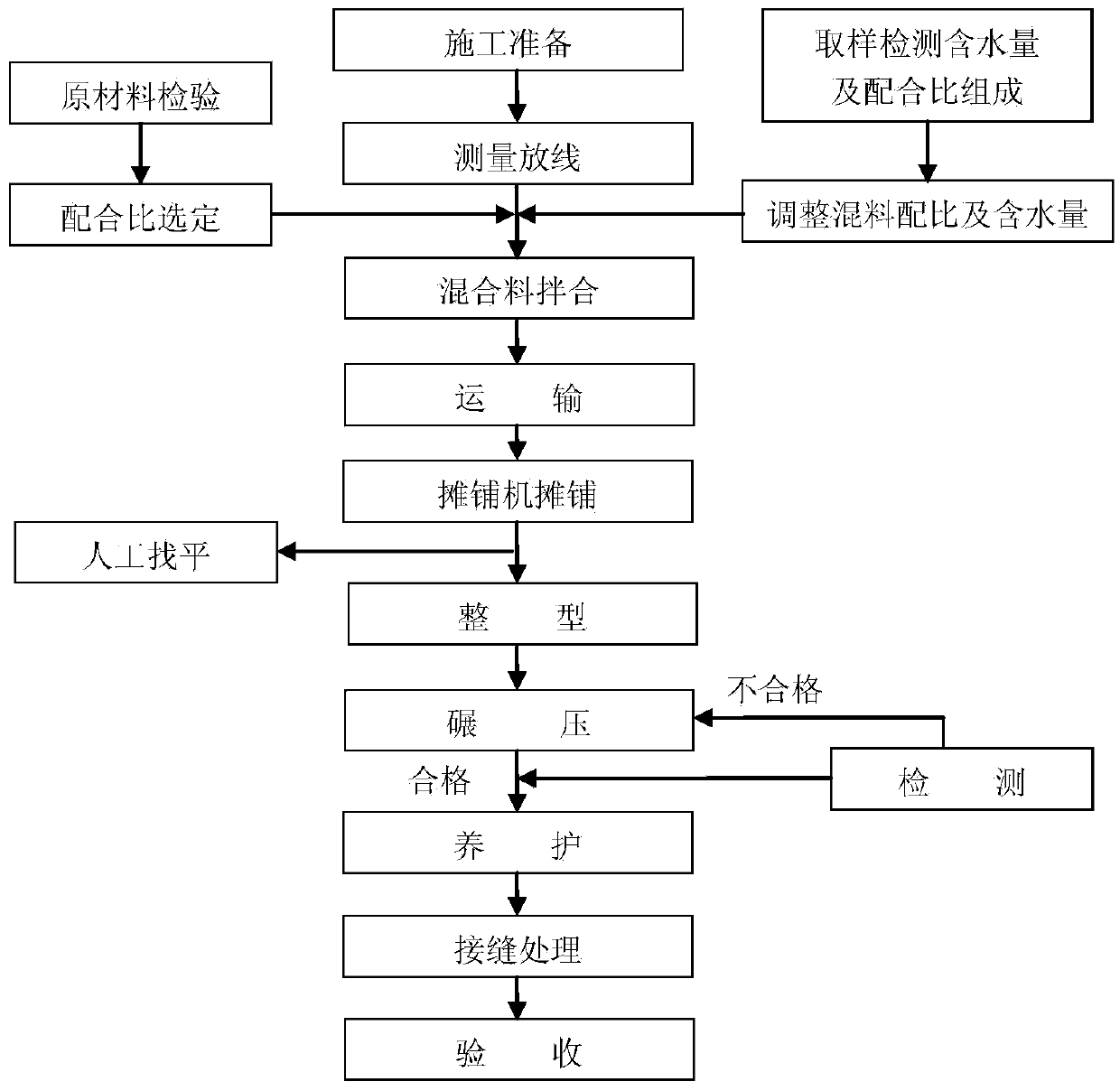

[0013] The technical scheme of the invention is a cement-stabilized coral reef sand construction process, which can be applied to Hainan engineering construction and can solve the problem of offshore transportation of sand and stone materials in a special geographical location of an island. Its specific implementation is as follows:

[0014] (1) Construction preparation

[0015] For construction stakeout, the total station is used for plane positioning and setting of elevation control piles along the road axis and sideline, and the construction control is carried out according to the control point drawing line.

[0016] (2) mixing

[0017] The cement-stabilized coral reef sand binder is mixed intensively by the factory mixing method, and is mixed by a WBD300 stabilized soil mixer. Aggregation, metering, conveying, mixing, storage and other processes are all automatically controlled. Regular inspection and calibration to ensure the normal operation of the mixer and the accur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com