Hydraulic expanding type movable joint

A live joint and expansion technology, which is applied in the direction of connecting components, garbage transmission, loading/unloading, etc., can solve problems such as polluting the environment, causing diseases, and unsafety, and achieves rapid connection and separation, convenient and flexible operation, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: refer to each accompanying drawing.

[0026] A hydraulic expansion joint, the structural composition of which includes:

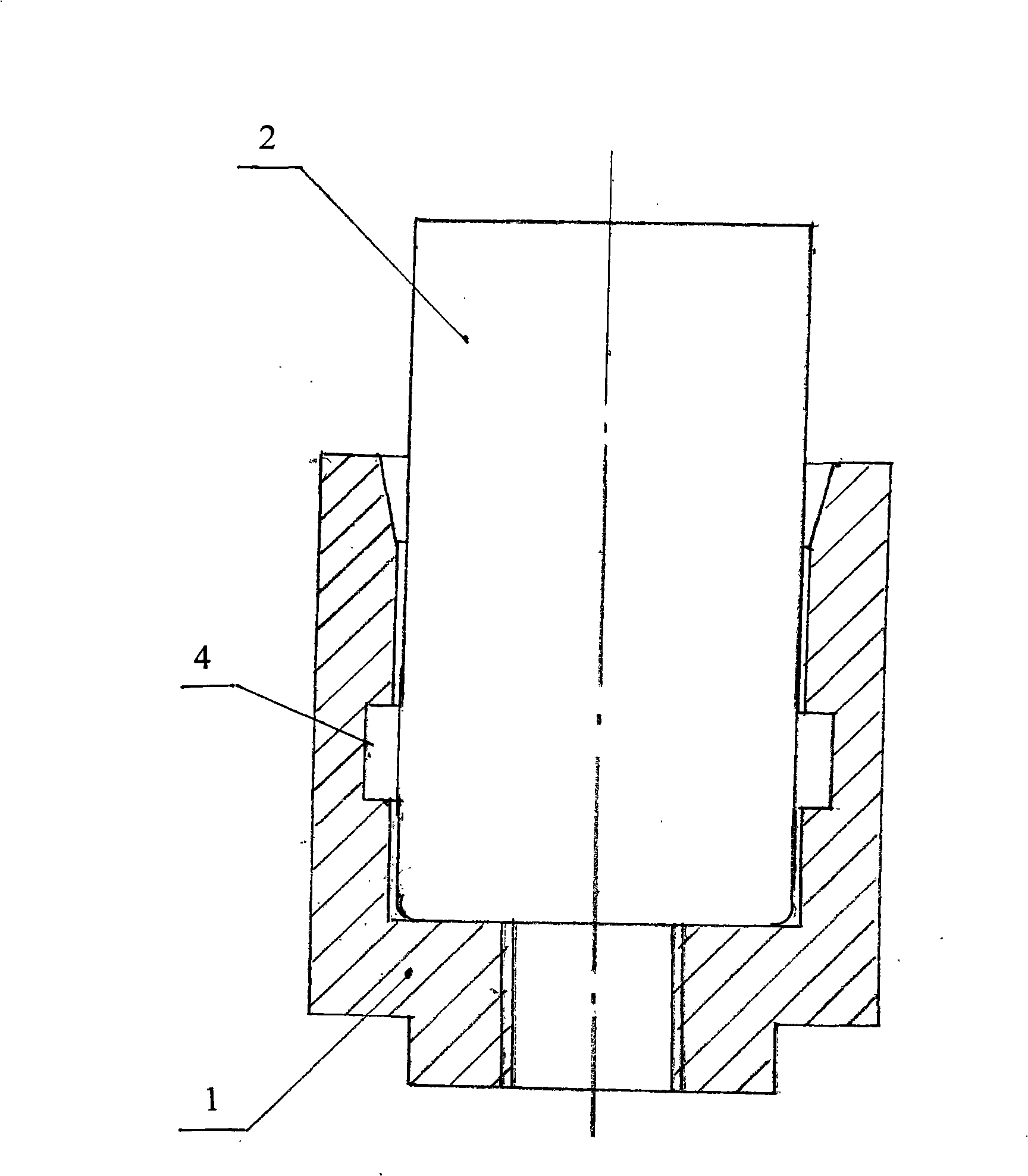

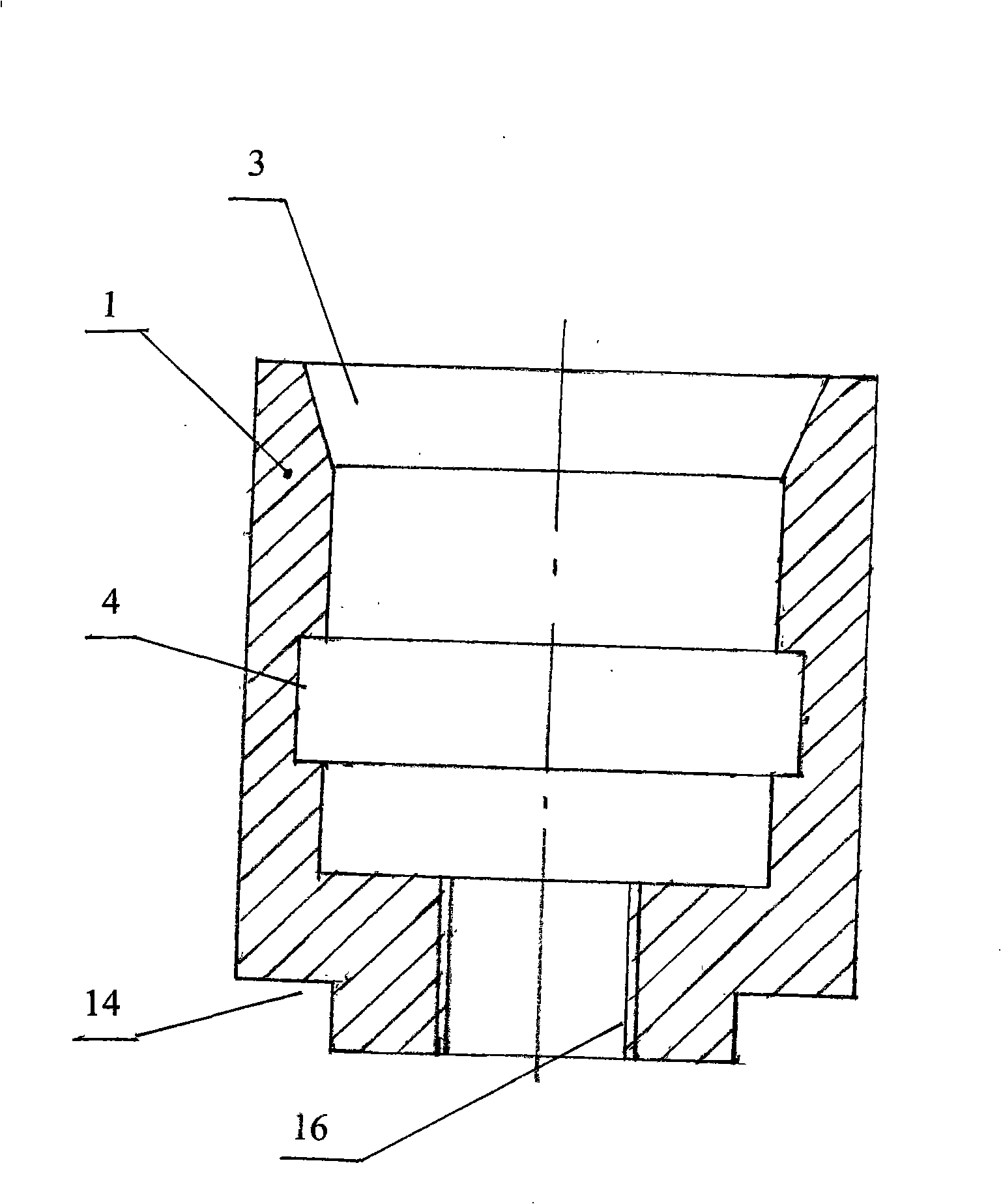

[0027] A female joint 1, the female joint 1 has a central hole 3, and an annular groove 4 is formed on the inner peripheral surface of the central hole 3;

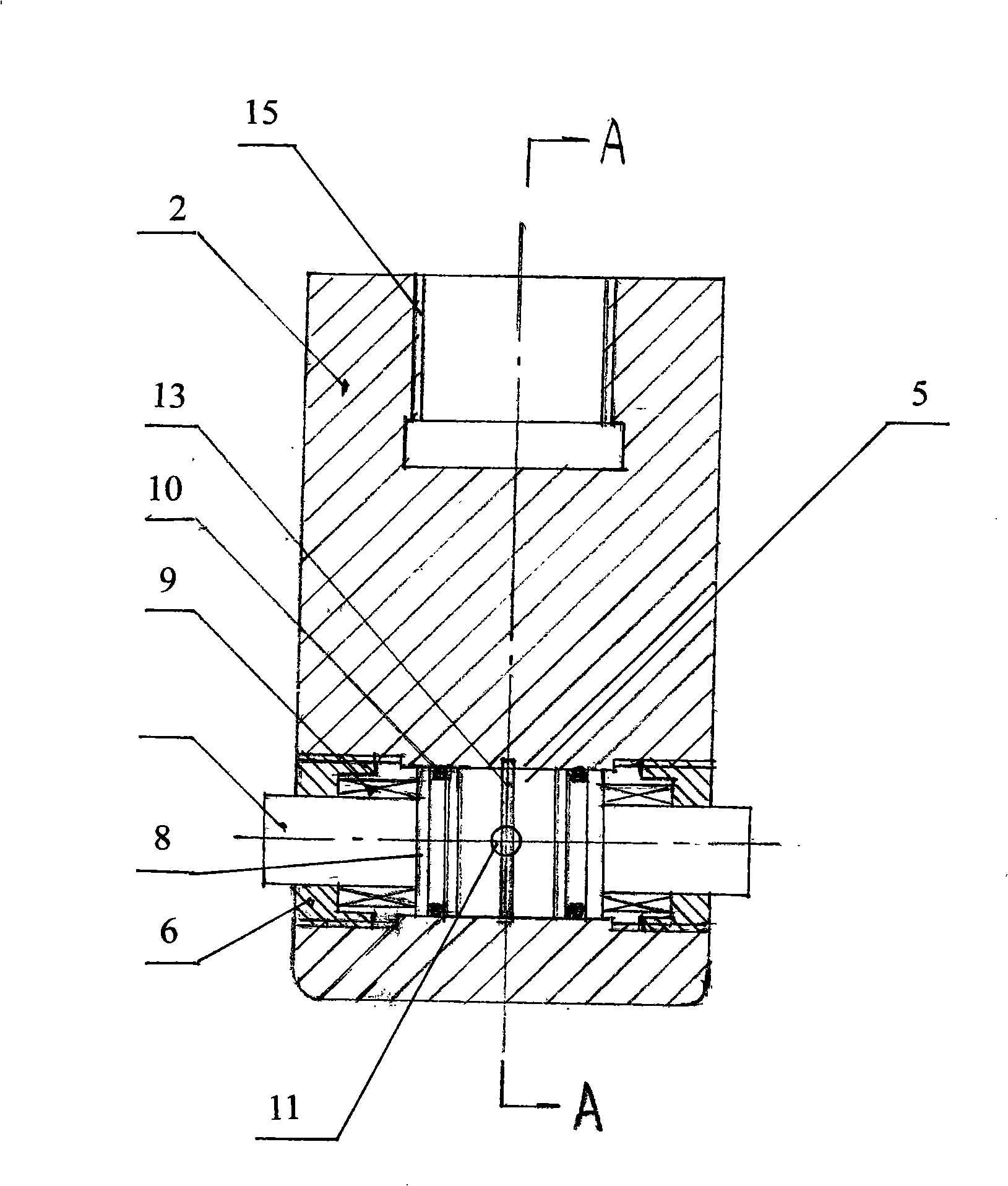

[0028] A male joint 2, a section of the male joint 2 is movable in the central hole 3 of the female joint 1; the lower section of the male joint 2 has a radial perforation 5, and the two ends of the radial perforation 5 have internal threads and are respectively fixedly connected with locking Coils 6, each locking coil 6 is movably socketed with a movable small shaft 7 with an annular boss 8 at the inner end, and a spring 9 and a sealing ring 10 are sleeved on the movable small shaft 7 in the radial perforation 5; There is an oil inlet and outlet hole 11 in the male joint 2 that one end communicates with the radial perforation 5 and the other end passes through.

[0029] A retaini...

Embodiment 2

[0032] Embodiment 2: refer to each accompanying drawing.

[0033] A hydraulic expansion joint, the structural composition of which includes:

[0034] A female joint 1, the female joint 1 has a central hole 3, and an annular groove 4 is formed on the inner peripheral surface of the central hole 3;

[0035] A male joint 2, a section of the male joint 2 is movable in the central hole 3 of the female joint 1; the lower section of the male joint 2 has a radial perforation 5, and the two ends of the radial perforation 5 have internal threads and are respectively fixedly connected with locking Coils 6, each locking coil 6 is movably socketed with a movable small shaft 7 with an annular boss 8 at the inner end, and a spring 9 and a sealing ring 10 are sleeved on the movable small shaft 7 in the radial perforation 5; There is an oil inlet and outlet hole 11 in the male joint 2 that communicates with the radial perforation 5 at one end and passes through at the other end;

[0036] A r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com