Loading method for measuring H points of seat simulation model

A simulation model and seat technology, which is applied in the field of measuring the loading of the H point of the seat simulation model, can solve the problem that the seat simulation model cannot measure the H point accurately, and achieves a time-saving and resource saving, low cost and high measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

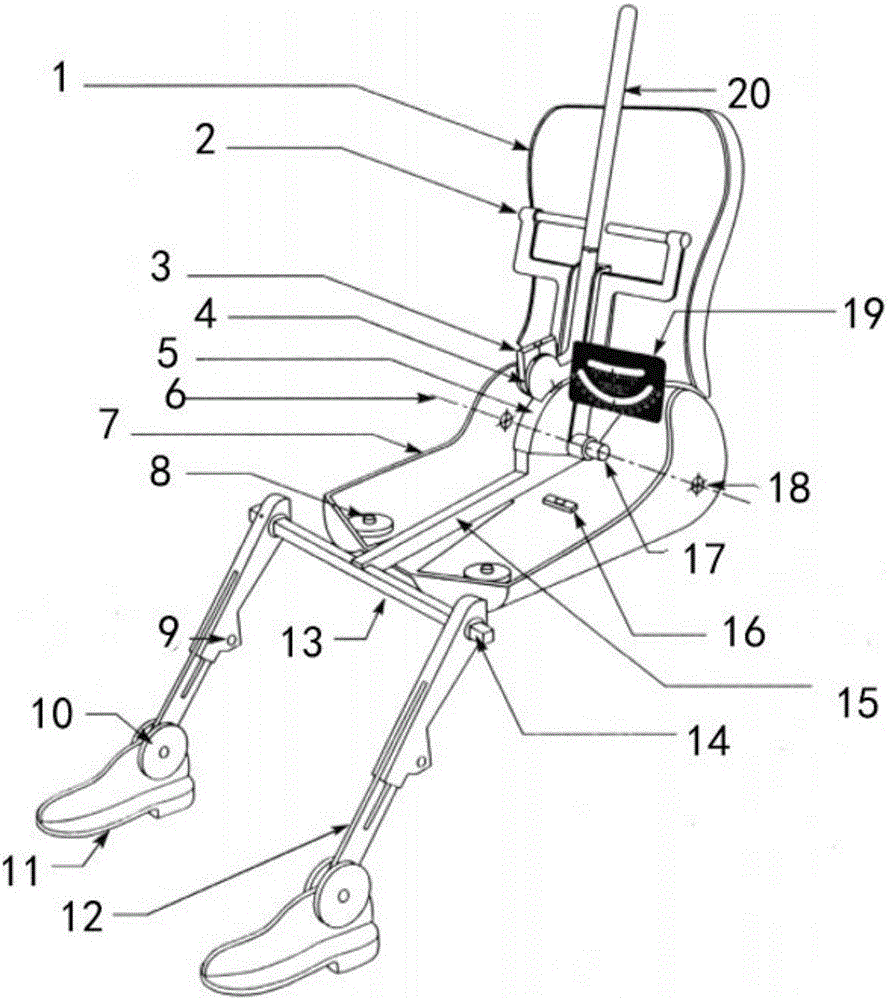

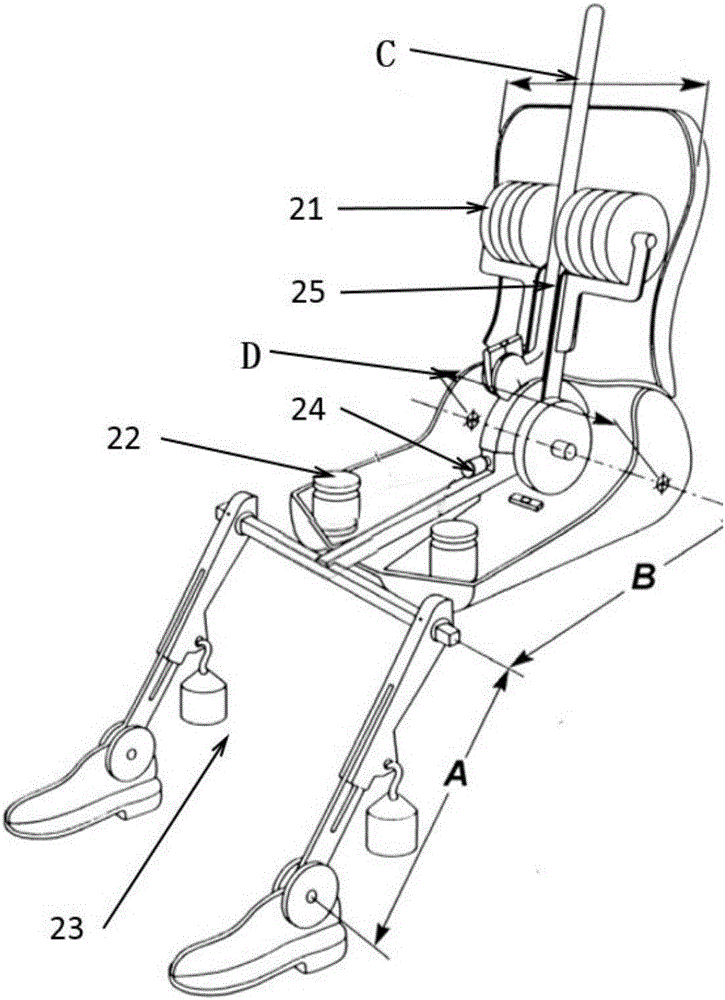

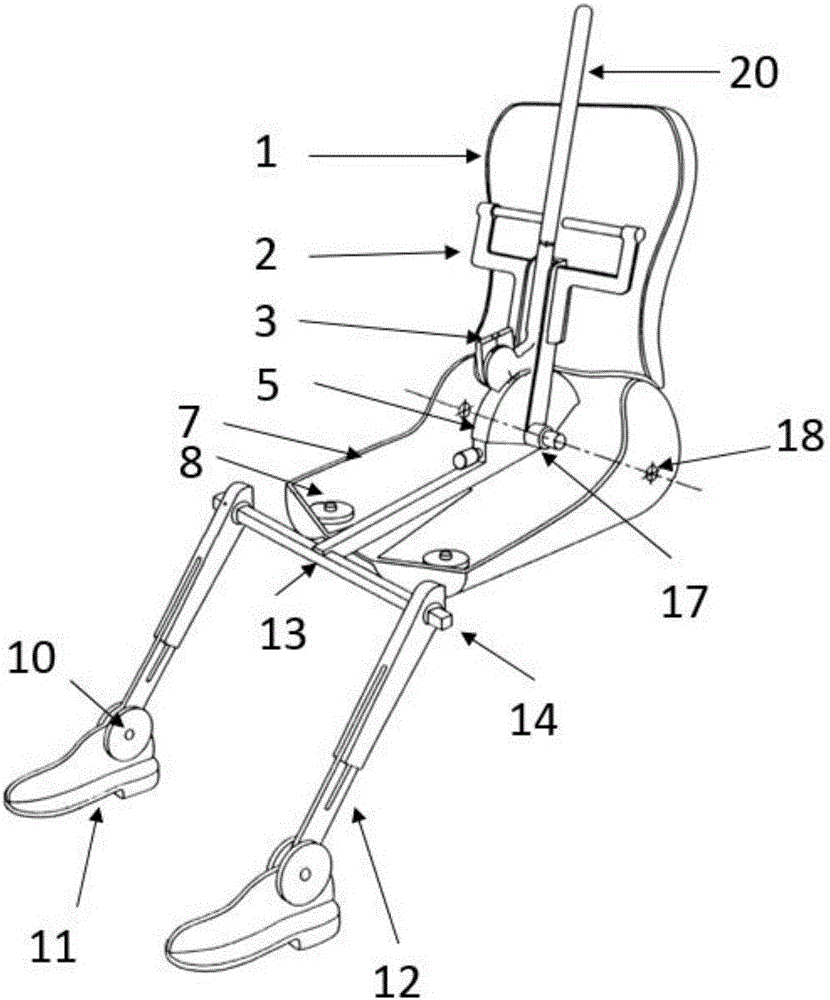

[0079] The following loading steps are for a seat using the 50th percentile H-point measuring instrument for loading. This embodiment measures the H point for a certain type of seat. During the loading process, the horizontal load required to maintain the H point measuring instrument is fixed, and the time interval for loading the load is constant. Therefore, in this embodiment, each application The horizontal load is a fixed value, the horizontal load loading time interval is the same, the friction coefficient between the H-point measuring instrument and the seat is set to 0.3, in terms of output settings: output a simulation animation file every 50 milliseconds, and output a simulation animation file every 10 milliseconds The contact force between the H-point measuring instrument and the seat outputs a three-dimensional coordinate value of the H-point every 5 milliseconds.

[0080] 1. Self gravity loading

[0081] refer to Figure 4 , Load the H-point measuring instrument ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com