Patents

Literature

102results about How to "Reduce the amount of calculation data" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

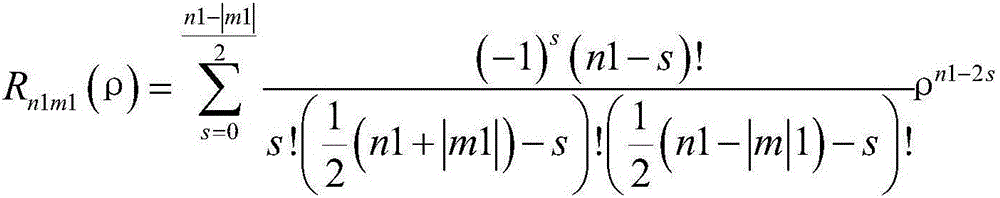

Multi-scale normal feature point cloud registering method

ActiveCN104143210AEvenly distributedRecognizable3D-image renderingSingular value decompositionFeature vector

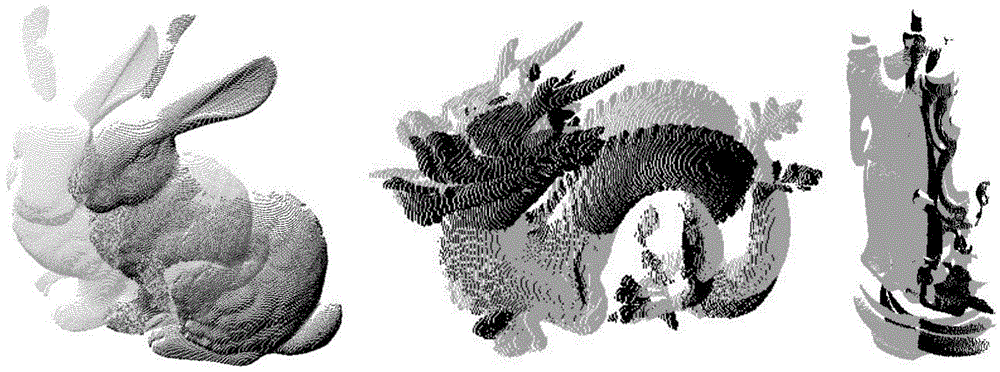

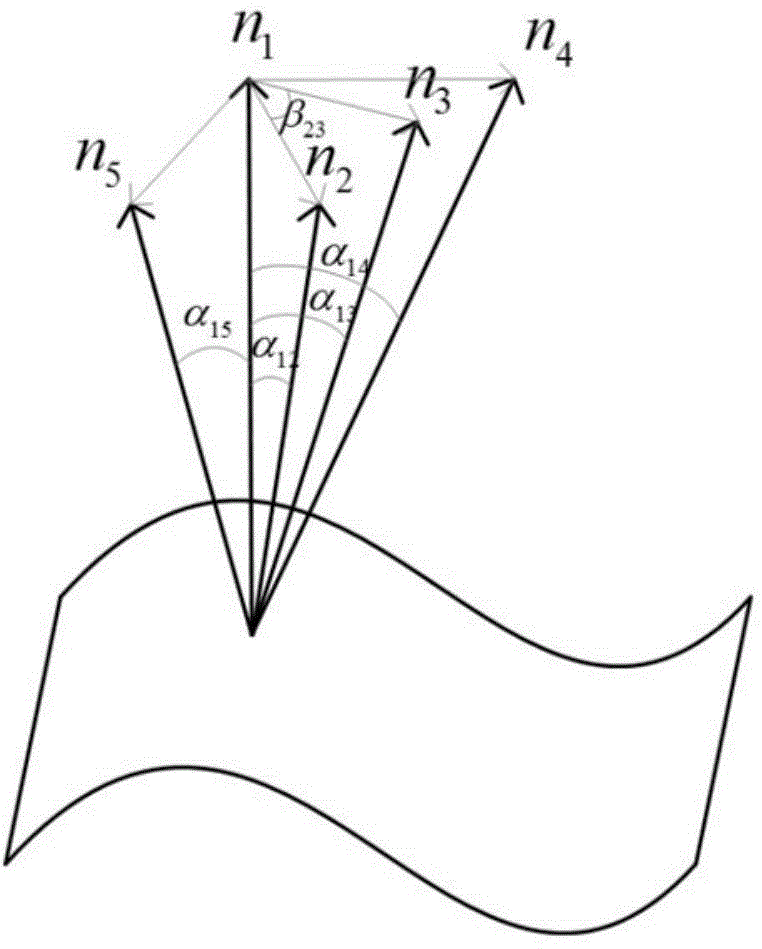

The invention relates to a multi-scale normal feature point cloud registering method. The multi-scale normal feature point cloud registering method is characterized by including the steps that two-visual-angle point clouds, including the target point clouds and the source point clouds, collected by a point cloud obtaining device are read in; the curvature of radius neighborhoods of three scales of points is calculated, and key points are extracted from the target point clouds and the source point clouds according to a target function; the normal vector angular deviation and the curvature of the key points in the radius neighborhoods of the different scales are calculated and serve as feature components, feature descriptors of the key points are formed, and a target point cloud key point feature vector set and a source point cloud key point feature vector set are accordingly obtained; according to the similarity level of the feature descriptors of the key points, the corresponding relations between the target point cloud key points and the source point cloud key points are preliminarily determined; the wrong corresponding relations are eliminated, and the accurate corresponding relations are obtained; the obtained accurate corresponding relations are simplified with the clustering method, and the evenly-distributed corresponding relations are obtained; singular value decomposition is carried out on the final corresponding relations to obtain a rigid body transformation matrix.

Owner:HARBIN ENG UNIV

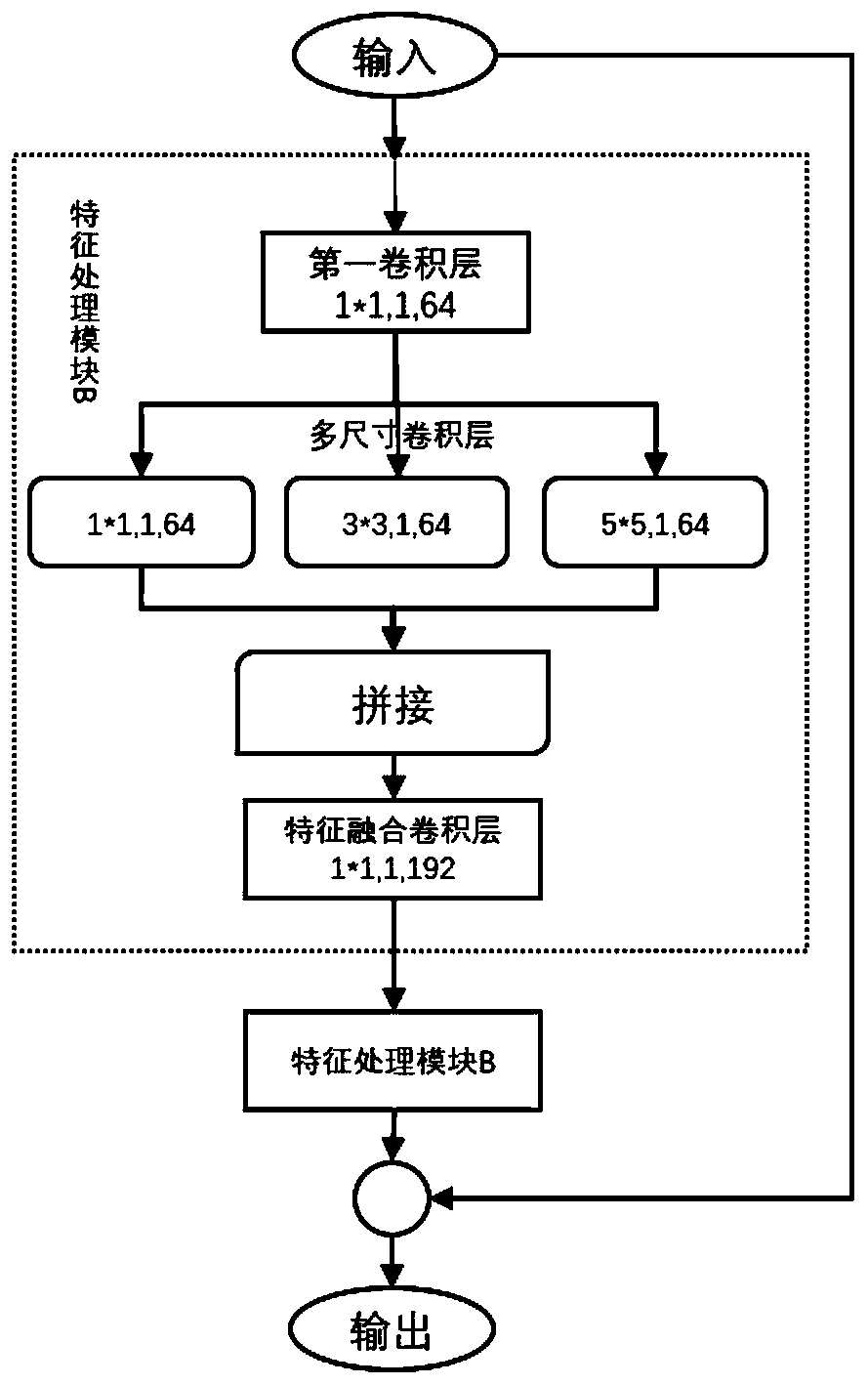

Real-time image semantic segmentation method based on lightweight full convolutional neural network

PendingCN110110692AReduce memory usageReduce the amount of calculation dataCharacter and pattern recognitionData setAlgorithm

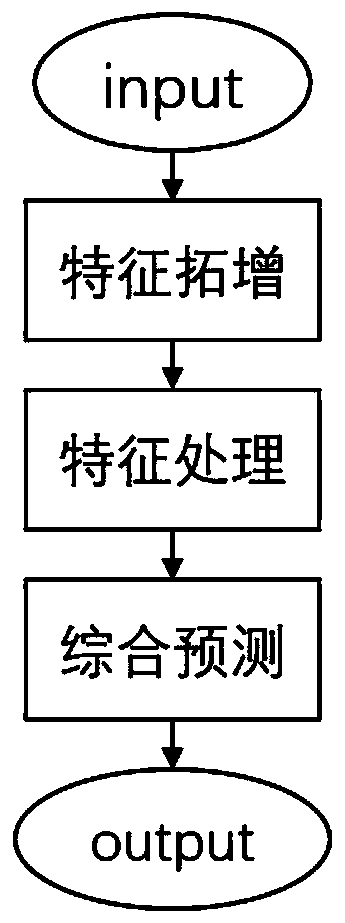

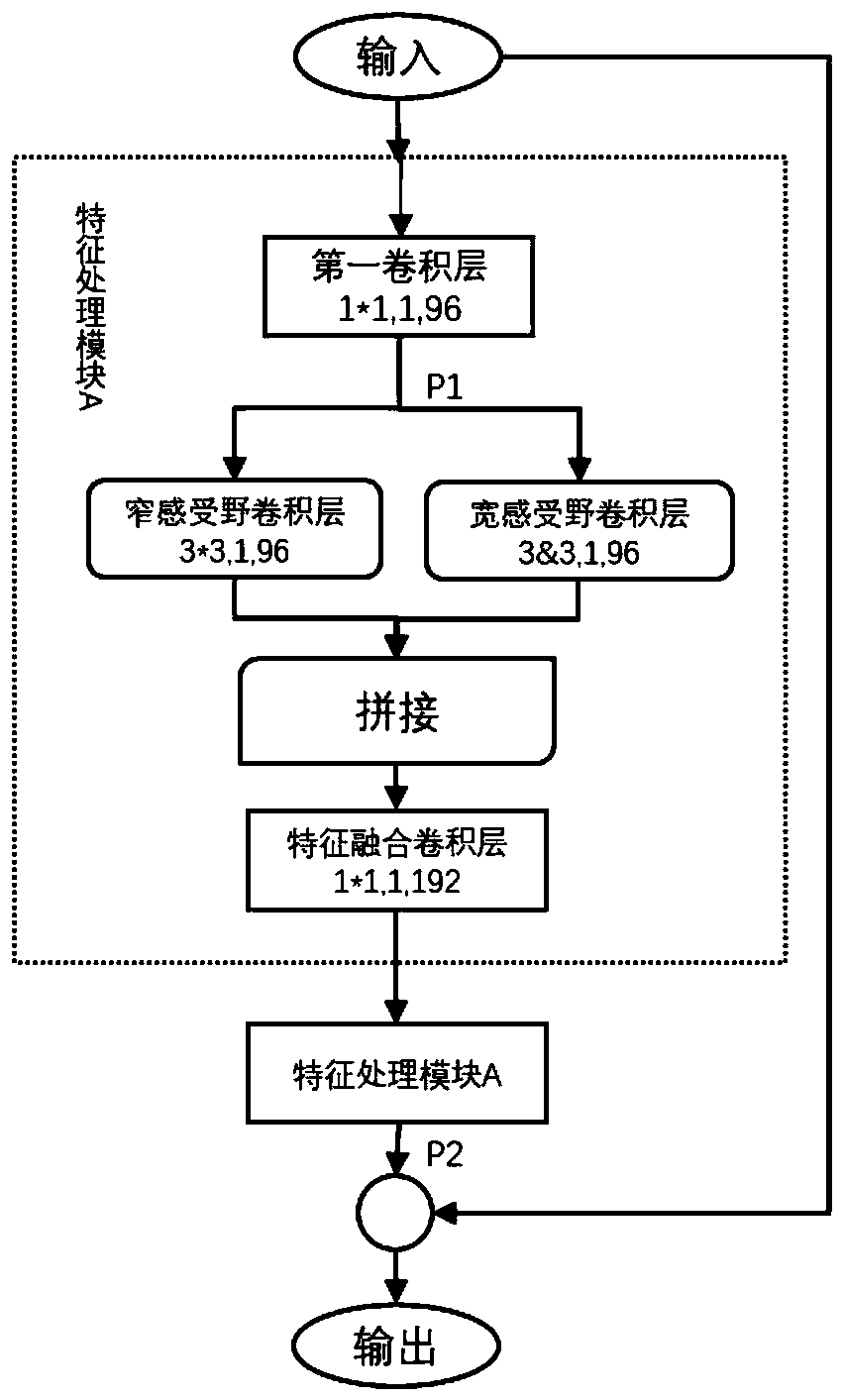

The invention discloses a real-time image semantic segmentation method based on a lightweight full convolutional neural network. The method comprises the following steps of 1) constructing a full convolutional neural network by using the design elements of a lightweight neural network, wherein the network totally comprises three stages of a feature extension stage, a feature processing stage and acomprehensive prediction stage, and the feature processing stage uses a multi-receptive field feature fusion structure, a multi-size convolutional fusion structure and a receptive field amplificationstructure; 2) at a training stage, training the network by using a semantic segmentation data set, using a cross entropy function as a loss function, using an Adam algorithm as a parameter optimization algorithm, and using an online difficult sample retraining strategy in the process; and 3) at a test stage, inputting the test image into the network to obtain a semantic segmentation result. According to the present invention, the high-precision real-time semantic segmentation method suitable for running on a mobile terminal platform is obtained by adjusting a network structure and adapting asemantic segmentation task while controlling the scale of the model.

Owner:NANJING UNIV

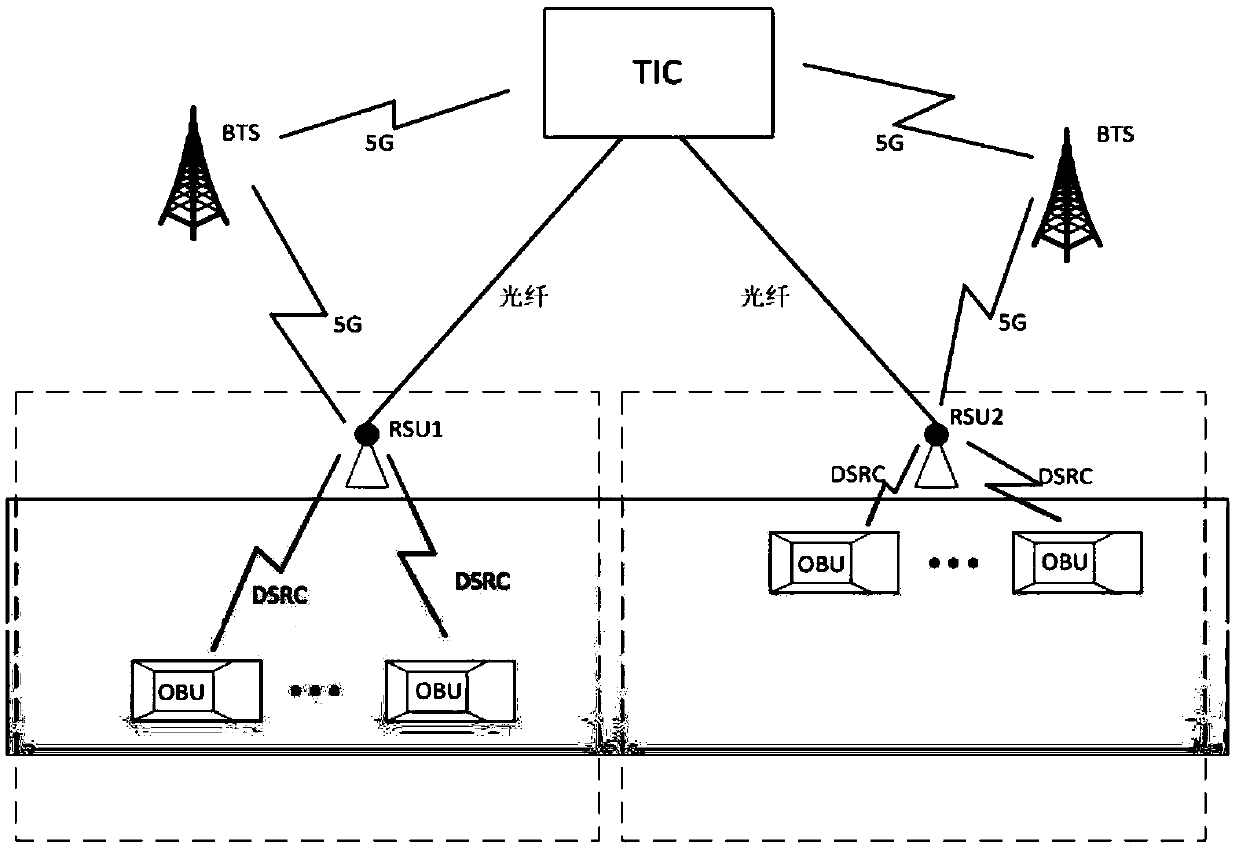

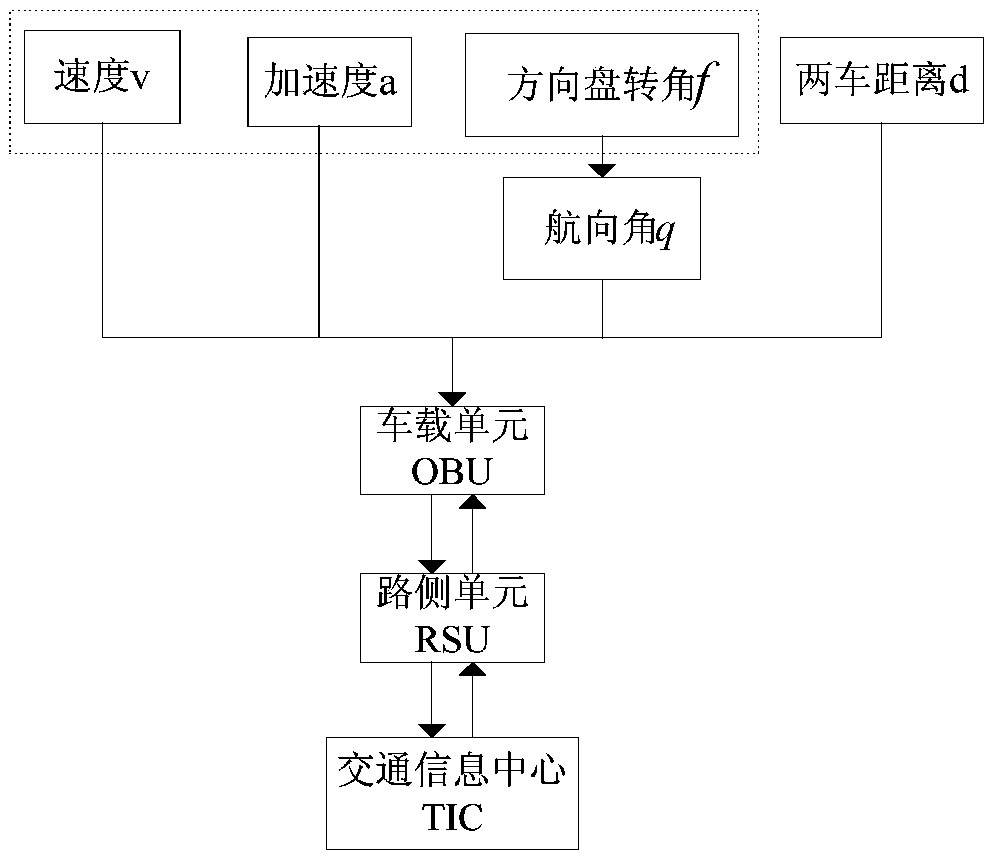

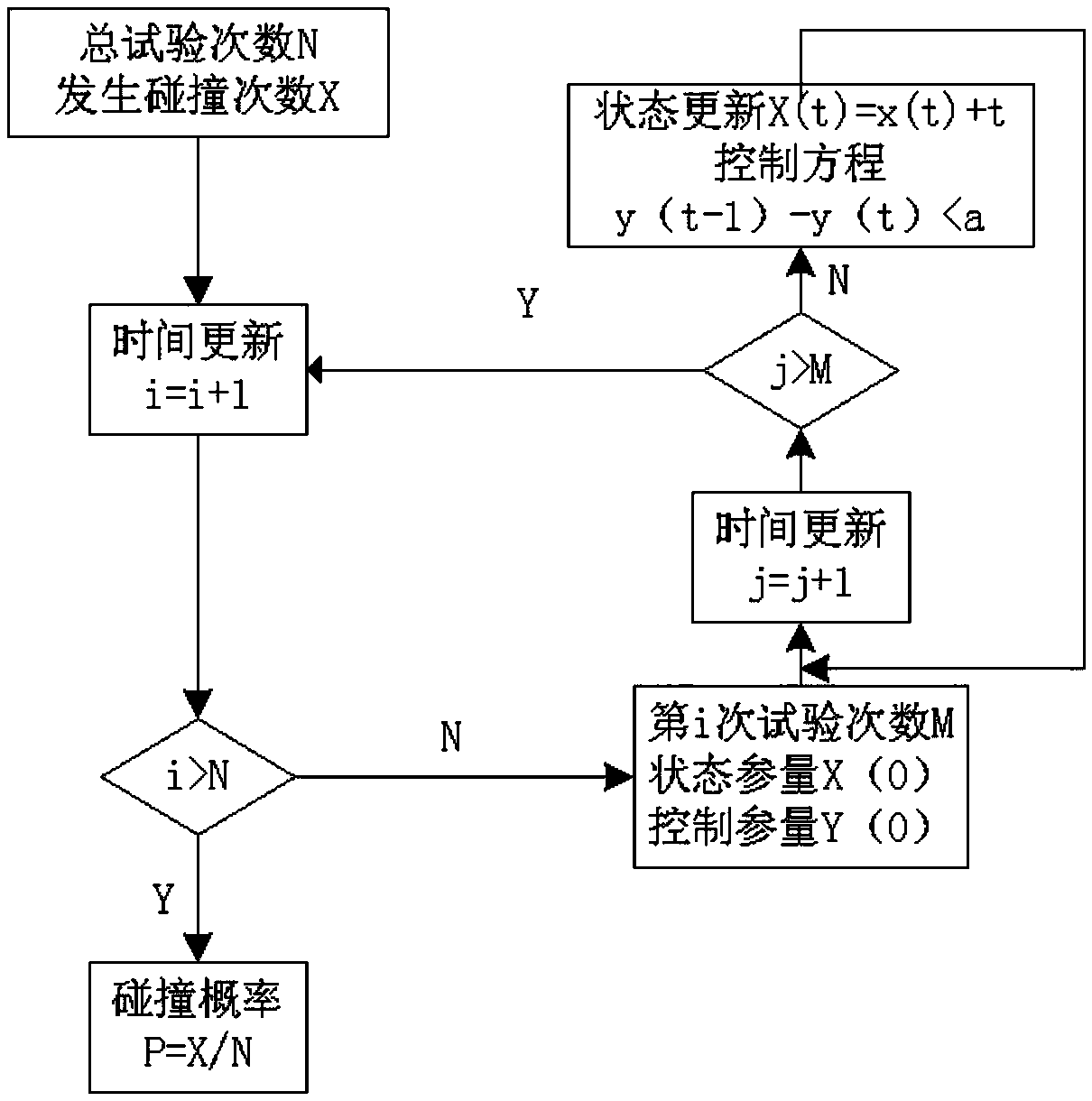

Vehicle collision risk algorithm and accident pre-warning method

ActiveCN105513425AImprove confidentialityFor precise controlAnti-collision systemsTraffic crashOn board

The invention discloses a vehicle collision risk algorithm and accident pre-warning method, which comprise an on-board unit (OBU), a road side unit (RSU), a traffic information center (TIC) and an information communication unit (ICU). The OBU is used for acquiring vehicle speed, accelerated speed, a steering wheel angle and other parameters, and combining with a road traffic system to acquire a track angle of a vehicle and a real-time distance between two vehicles; the OBU transmits the parameters to the belonged RSU through a DSRC (Dedicated Short Range Communication) technology; the RSU transmits the vehicle parameters in an area to the TIC for risk calculation through an optical fiber / 5G technology; the result is forwarded to the OBU for pre-warning through the RSU. According to the vehicle collision risk algorithm and accident pre-warning method, traffic accidents can be prevented and controlled accurately, and thus the traffic jam and the frequent accidents can be effectively avoided.

Owner:JIANGSU UNIV

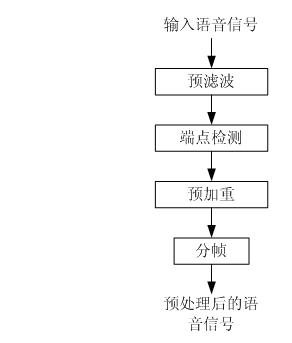

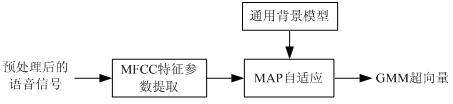

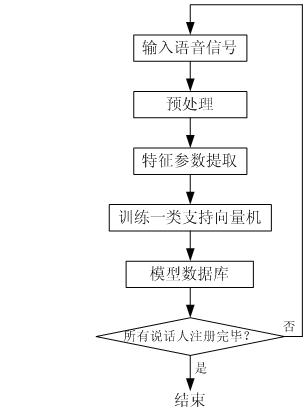

Method for quickly recognizing speaker

ActiveCN102664011AReduce the amount of calculation dataFast trainingSpeech recognitionExtensibilityOne-class classification

The invention provides a method for quickly recognizing a speaker and belongs to speaker recognition methods. The method comprises the following steps of: combining a Gaussian mixture model, and taking the supervector of the Gaussian mixture model as the feature parameter of the speaker; taking the supervector of the Gaussian mixture model as input, designing a one-class support vector machine classifier; and training N classifiers corresponding to N speakers, thus obtaining a voice sample of one speaker from one classifier. By utilizing the method, the speaker recognition speed is increased; for every new registered speaker, only one one-class support vector machine classifier is trained for the new speaker, so that the speaker recognition system has good extensibility.

Owner:JILIN UNIV

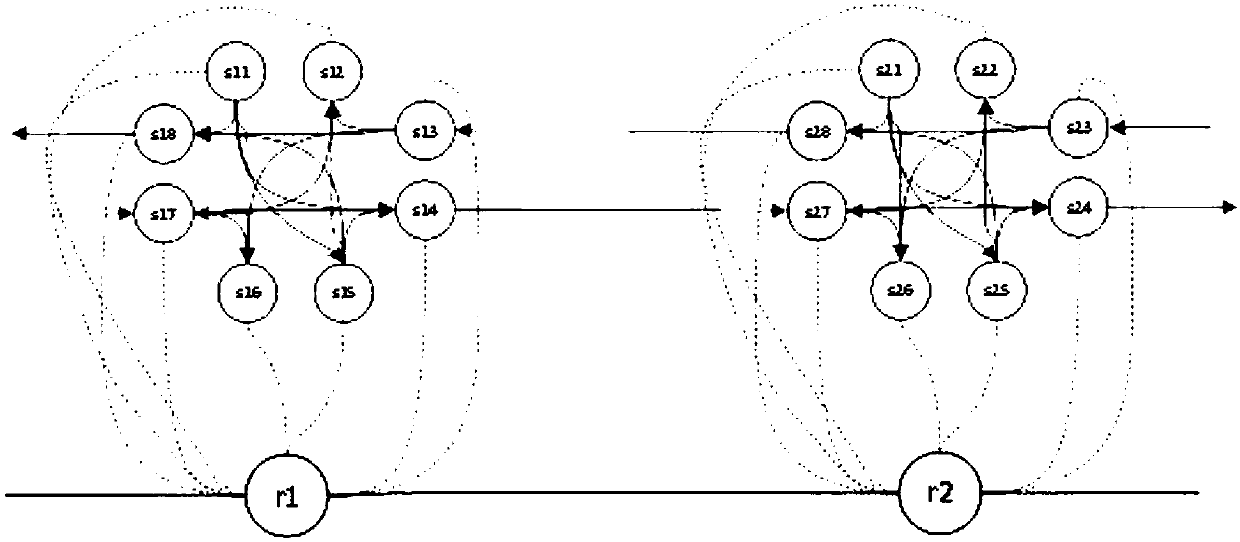

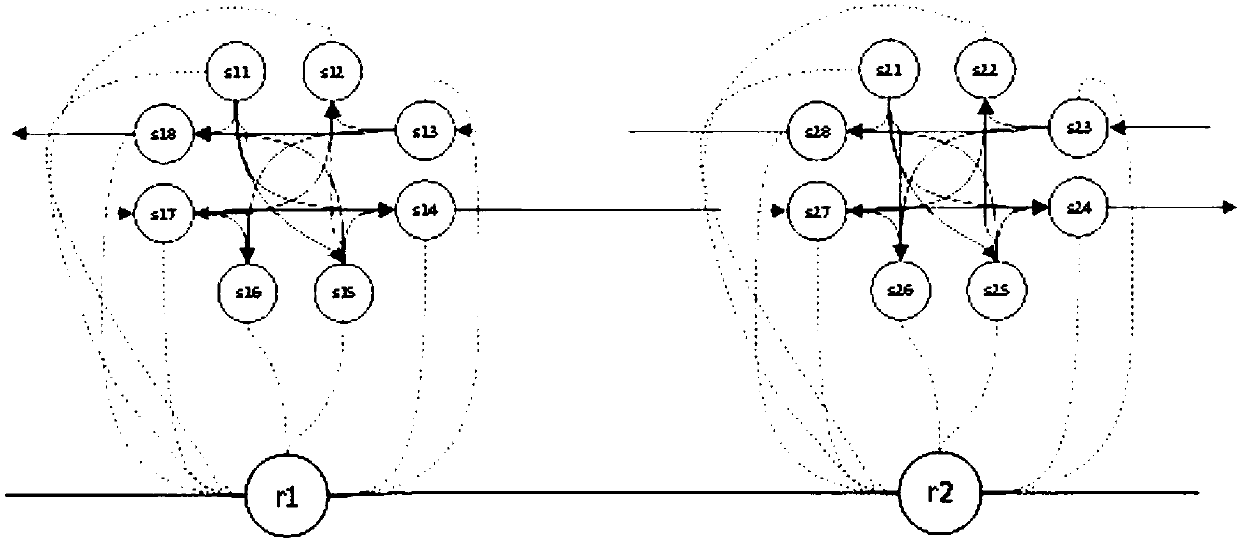

Method for discovering congestion points, congestion lines and congestion areas based on composite network

ActiveCN108109382AReduce the amount of calculation dataEasy to handleParticular environment based servicesDetection of traffic movementNetwork structureOperability

The invention belongs to the field of traffic condition prediction, and relates to a method for discovering congestion points, congestion lines and congestion areas based on a composite network. The composite network in the method is composed of two or more sub networks and connecting edges between the sub networks. The sub networks are independent networks constituting the composite network. Thecomposite network includes an intersection network and a sensor network. The sensor network takes traffic sensors at intersections as nodes, and the sensors are related by connecting edges. The intersection network takes intersections as nodes, and connecting edges are established according to whether the intersections can be connected. On the basis of the intersection network, the definitions ofa congestion index, a congestion point, a congestion line and a congestion area are given. Calculation is carried out based on the network structure. The method specifically comprises the steps as follows: first, defining a congestion index Ti, a congestion point, a congestion line and a congestion area; then, quantifying the congestion level; and finally, analyzing and calculating congestion points, congestion lines and congestion areas. The method is designed ingeniously, has good operability and practicability, and has a wide market prospect.

Owner:QINGDAO UNIV

Identity authentication method and identity authentication system based on human face

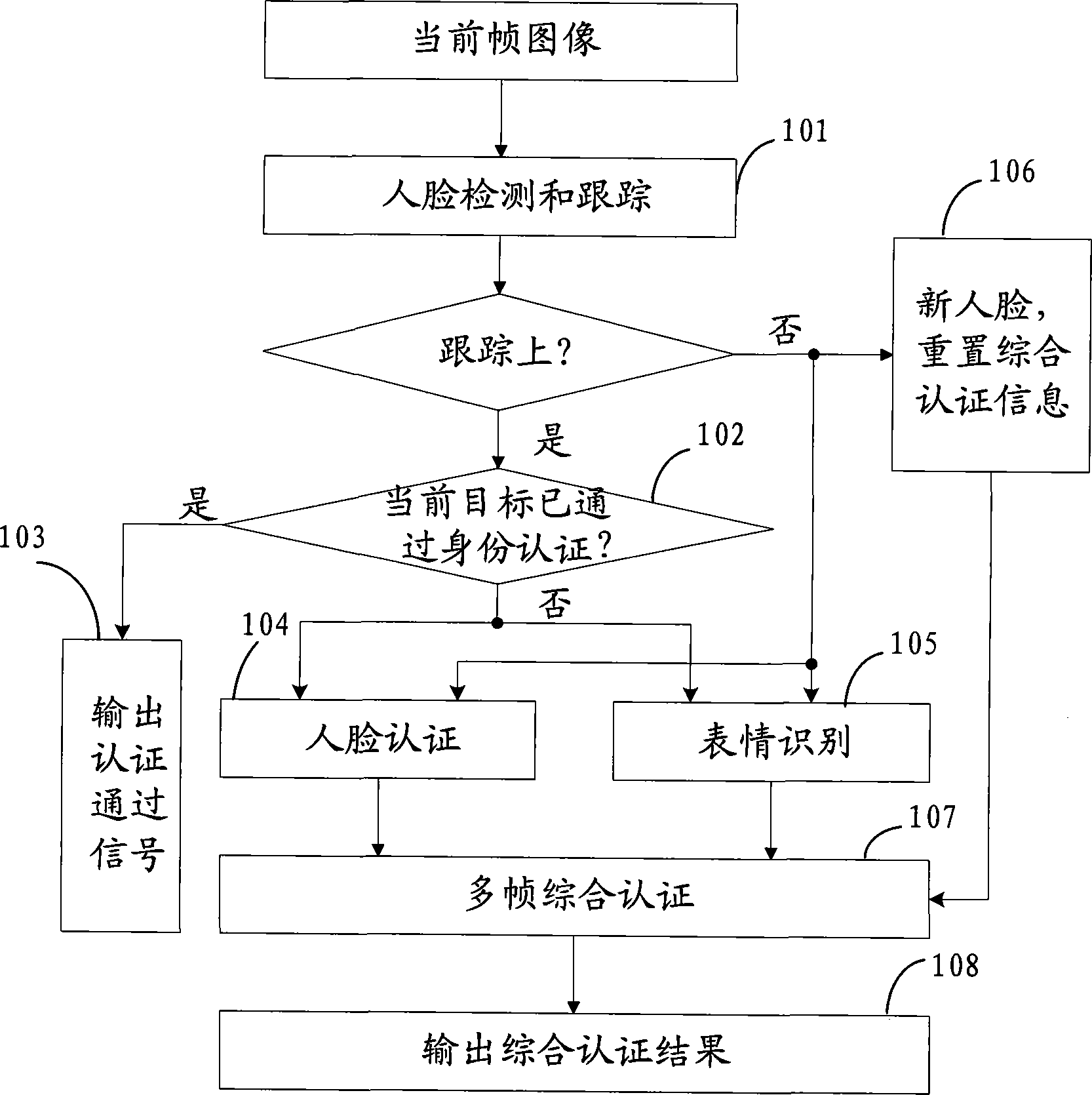

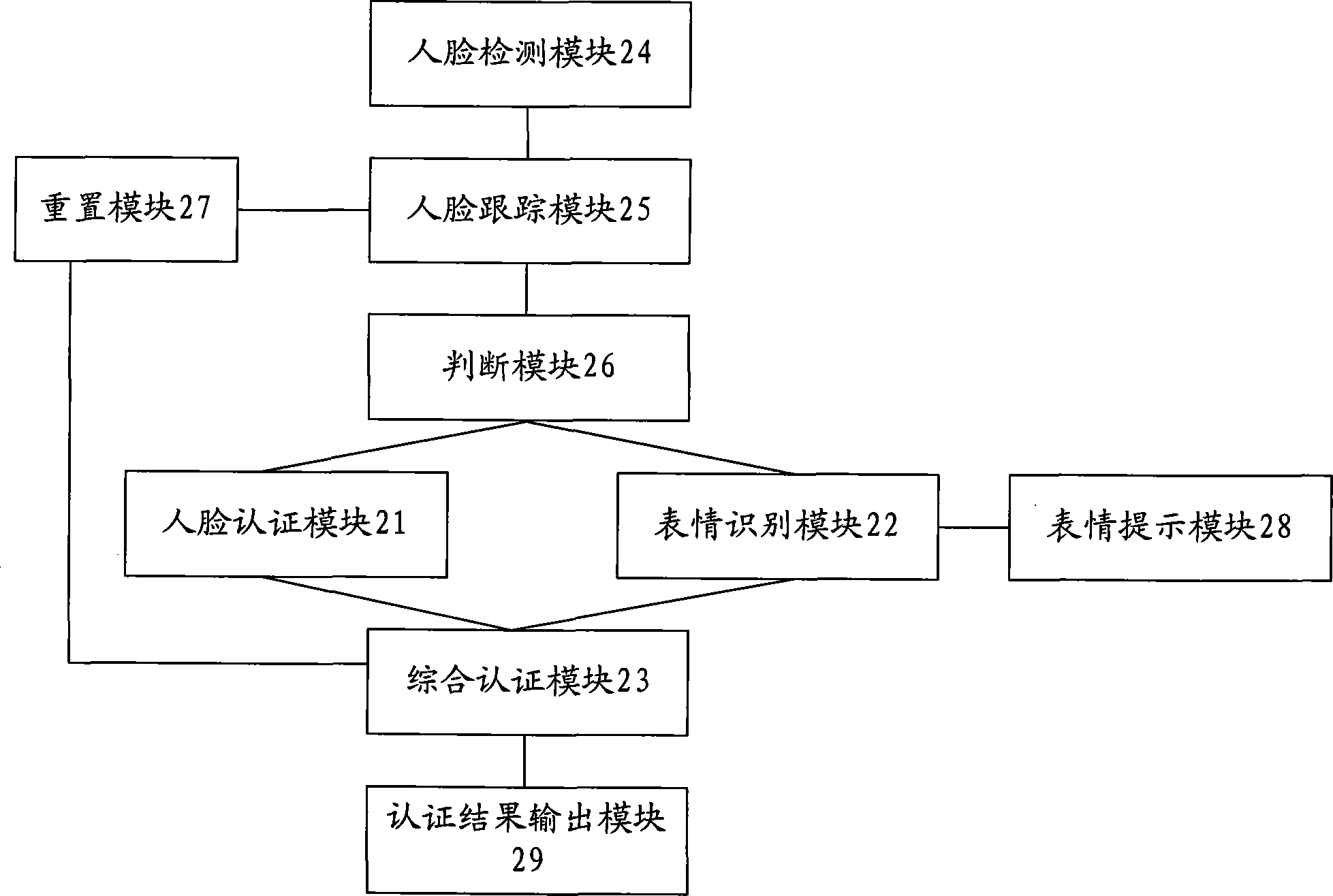

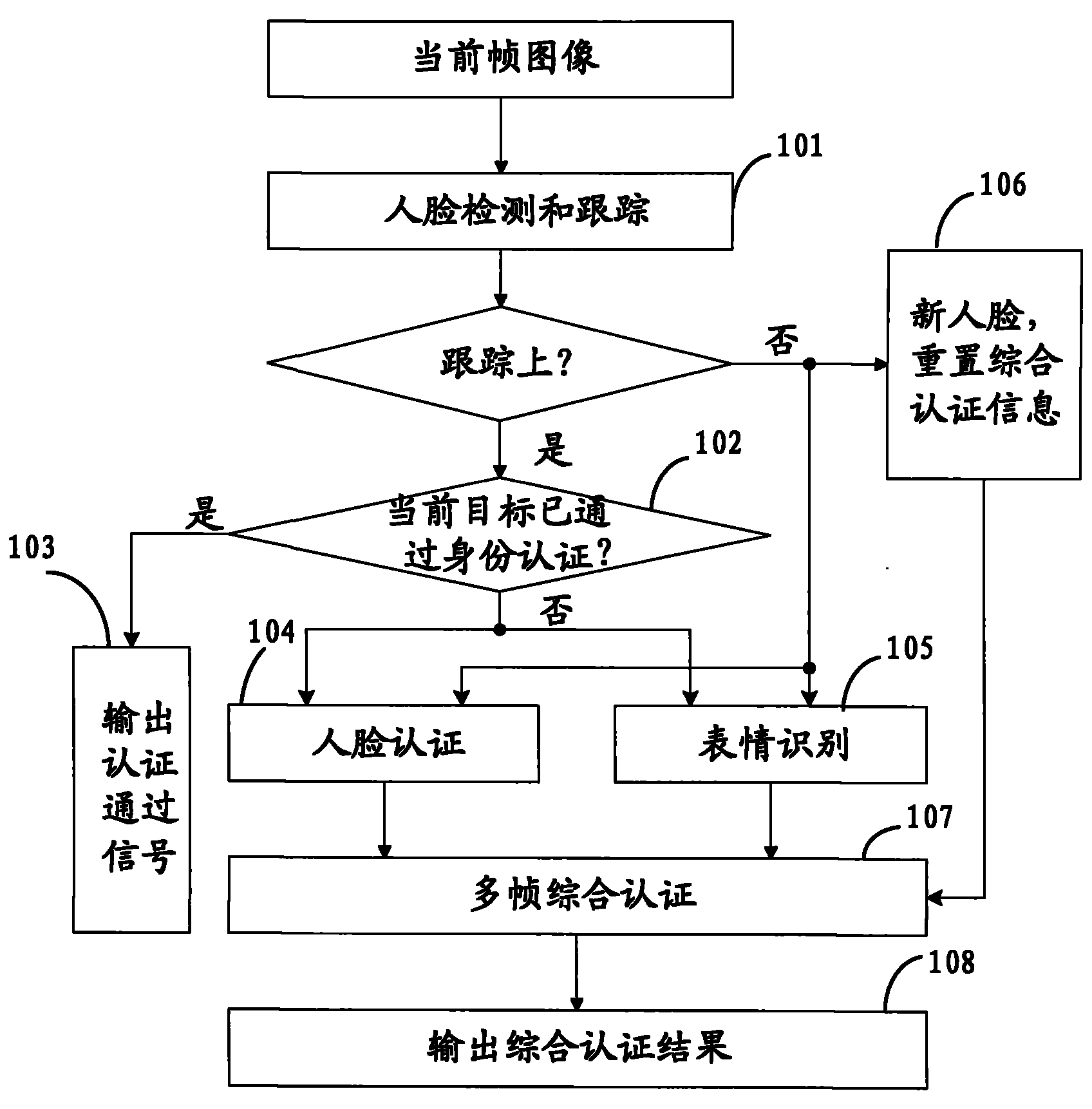

ActiveCN102385703AImprove authentication capabilitiesQuick distinctionCharacter and pattern recognitionPattern recognitionAuthentication system

The invention provides an identity authentication method and an identity authentication system based on a human face, which are used for solving the problem of distinguishing real persons from photos in the authentication process of the human face. The identity authentication method comprises the following steps of: carrying out human face authentication and facial expression recognition on a current frame image; carrying out comprehensive authentication on a human face authentication result and a facial expression recognition result of a continuous multiframe according to a preset strategy; and if the comprehensive authentication result is human face authentication pass and at least comprises two expressions, passing the identity authentication of the human face. According to the identity authentication method and the identity authentication system provided by the invention, by combining the expression recognition with human face recognition, the authentication performance is improved and the phenomenon that a jactitator passes the authentication by using a photo is avoided.

Owner:GUANGDONG VIMICRO

Method for discovering congestion time period based on composite network

ActiveCN108320506AReduce the amount of calculation dataEasy to handleDetection of traffic movementTraffic networkPeriod Analysis

The invention belongs to the field of traffic condition prediction, and relates to a method for discovering a congestion time period based on a composite network. According to the method, a compositenetwork of an intersection network and a sensor network is constructed based on a complex network theory, and a congestion time period in the traffic network can be accurately judged. The method is implemented specifically according to the following steps: firstly, a congestion index Ti, a congestion time period and congestion level quantization are defined, then the congestion time period is calculated through establishing a mapping relation between the intersection network and the sensor network and performing congestion time period analysis, and finally frequent congestion time period analysis is performed. The model established according to the method is simple, the calculation data amount is small, the processing process is concise and clear, the operability and the practicability aregood, and effective implementation is facilitated. Meanwhile, the overall design is ingenious in conception, the required infrastructure are easy to obtain, the prediction process is simple, the application environment is friendly, and the market prospect is broad.

Owner:QINGDAO UNIV

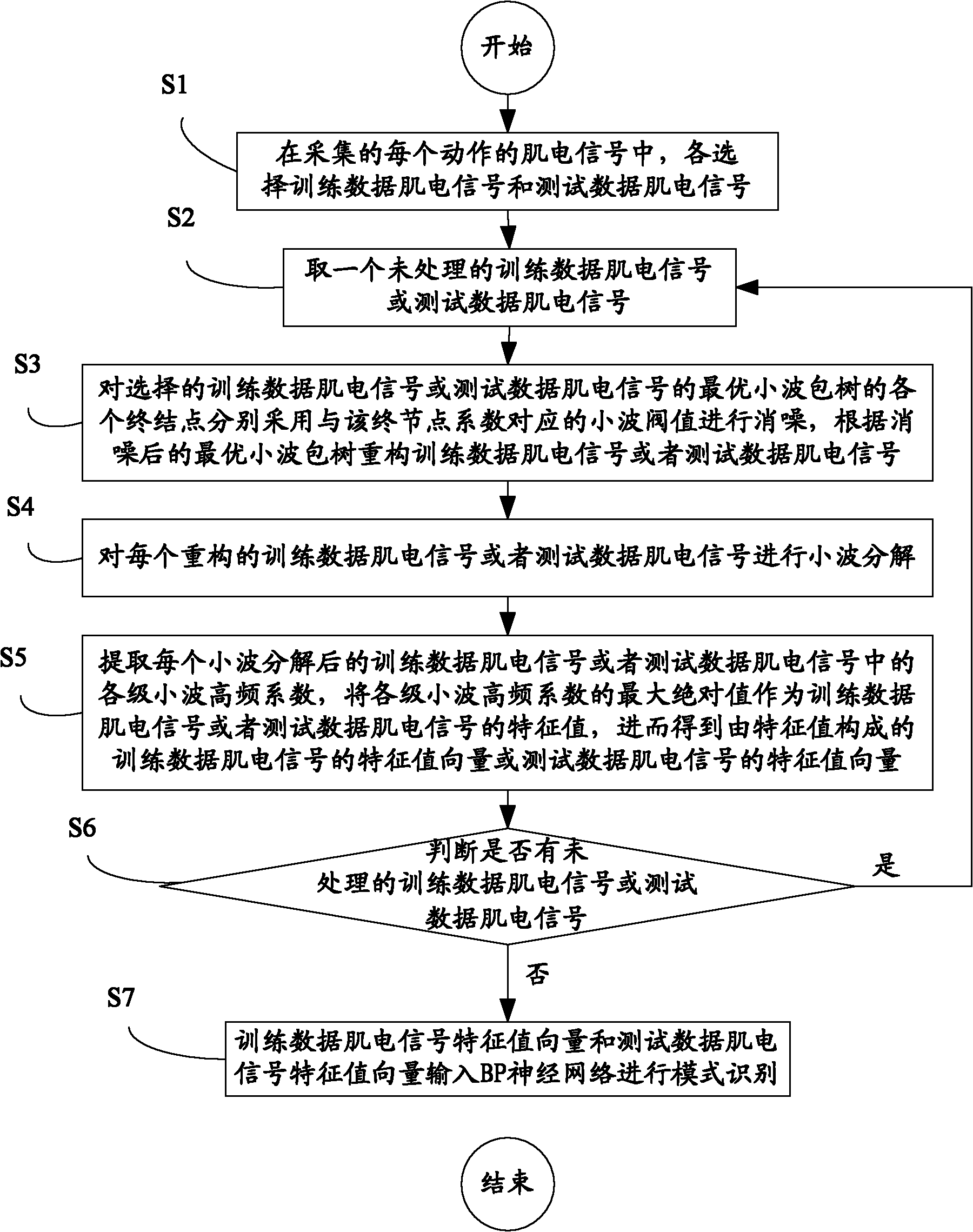

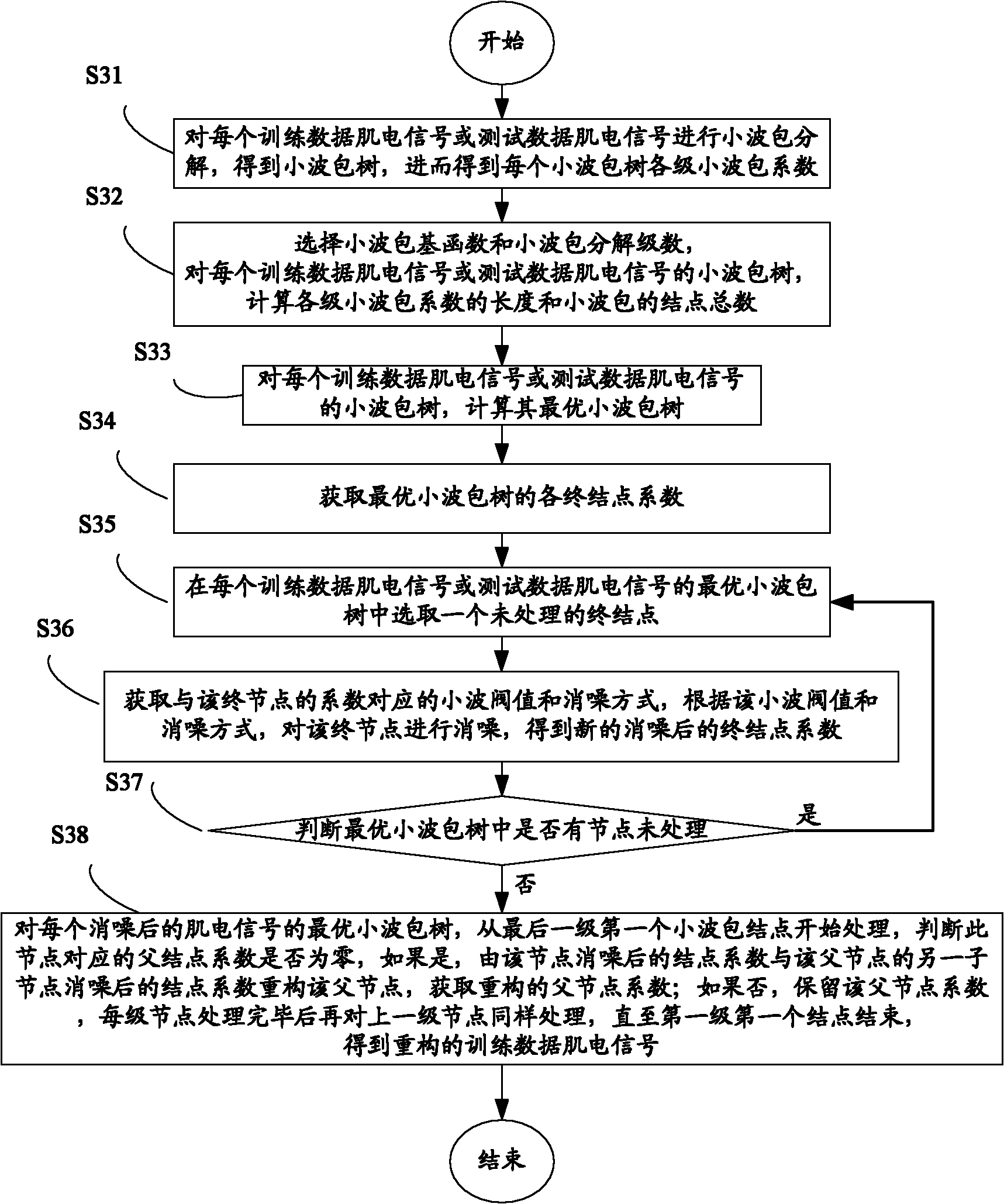

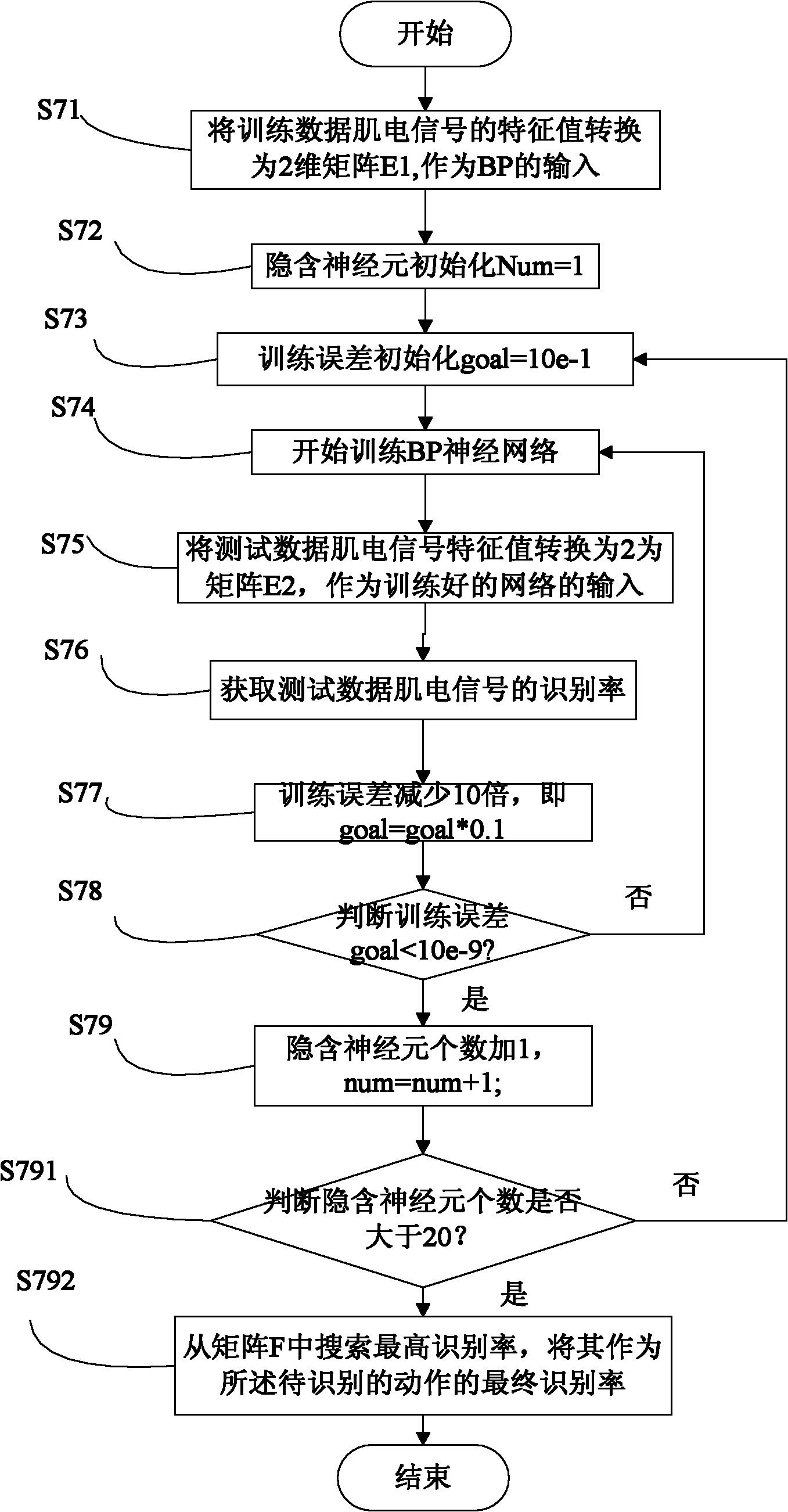

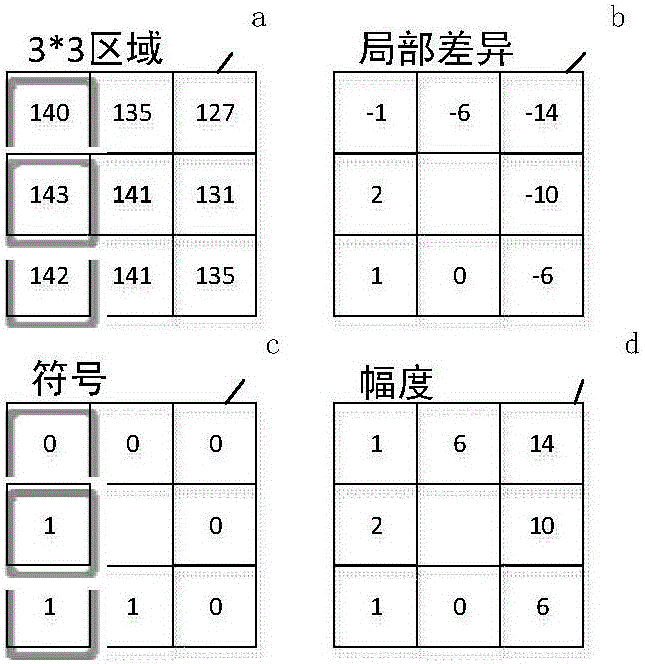

Denoising, feature extraction and pattern recognition method for human body surface electromyography signals

InactiveCN102073881AImprove recognition rateAdaptableCharacter and pattern recognitionNeural learning methodsHuman bodyFeature vector

The invention discloses a denoising, feature extraction and pattern recognition method for human body surface electromyography signals, which comprises the following steps: performing best wavelet packet node denoising on the human body surface electromyography signals; performing wavelet decomposition on the human body surface electromyography signals after denoising, and extracting maximum absolute values of all levels of wavelet high-frequency coefficients as feature vectors; and inputting the extracted feature vectors into a back propagation network for performing training and pattern recognition. With the adoption of the best wavelet packet leaf node denoising method provided by the invention, noise carried in the electromyography signals can be effectively removed, and useful information can be retained; the maximum absolute values of the wavelet high-frequency coefficients can well reflect features of the human body surface electromyography signals, thereby having obvious advantages in comparison with the existing feature value method; and the relatively high recognition effect can be obtained by searching optimal hidden neurons and training errors of the back propagation network.

Owner:WUHAN UNIV OF TECH

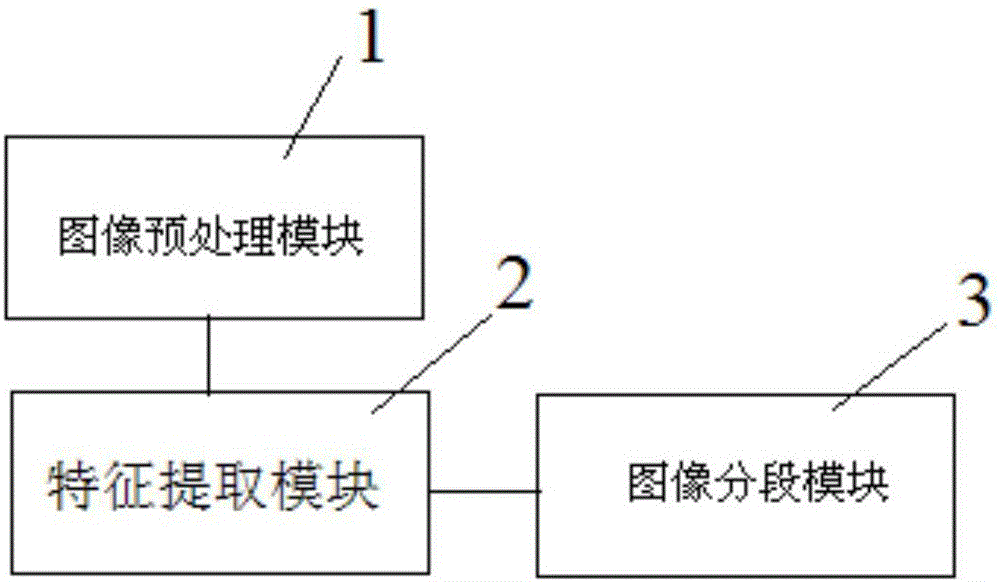

Automatic segmentation system and method for digestive tract internal image

ActiveCN106204599AImplement segmentationReduce the number of reading imagesImage enhancementImage analysisAutomatic segmentationFeature extraction

The invention discloses an automatic segmentation system for a digestive tract internal image. The system comprises an image preprocessing module, a feature extraction module and an image segmentation module, wherein the signal output end of the image preprocessing module is connected with the signal input end of the feature extraction module, and the signal output end of the feature extraction module is connected with the signal input end of the image segmentation module. Through the automatic segmentation system, the time for a doctor to search for images of different parts of the digestive tract can be shortened, the workload is reduced, and work efficiency is improved.

Owner:安翰科技(武汉)股份有限公司

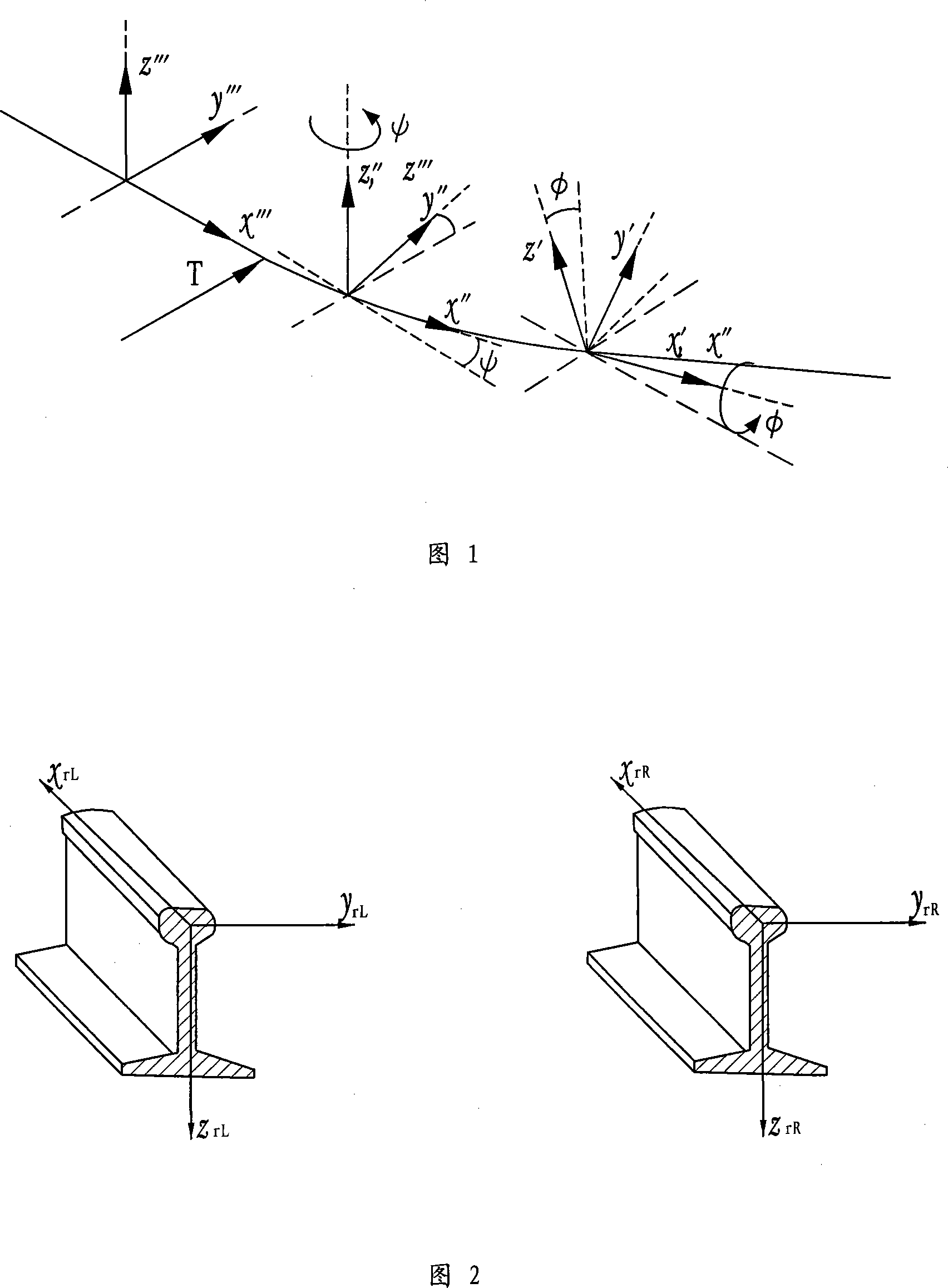

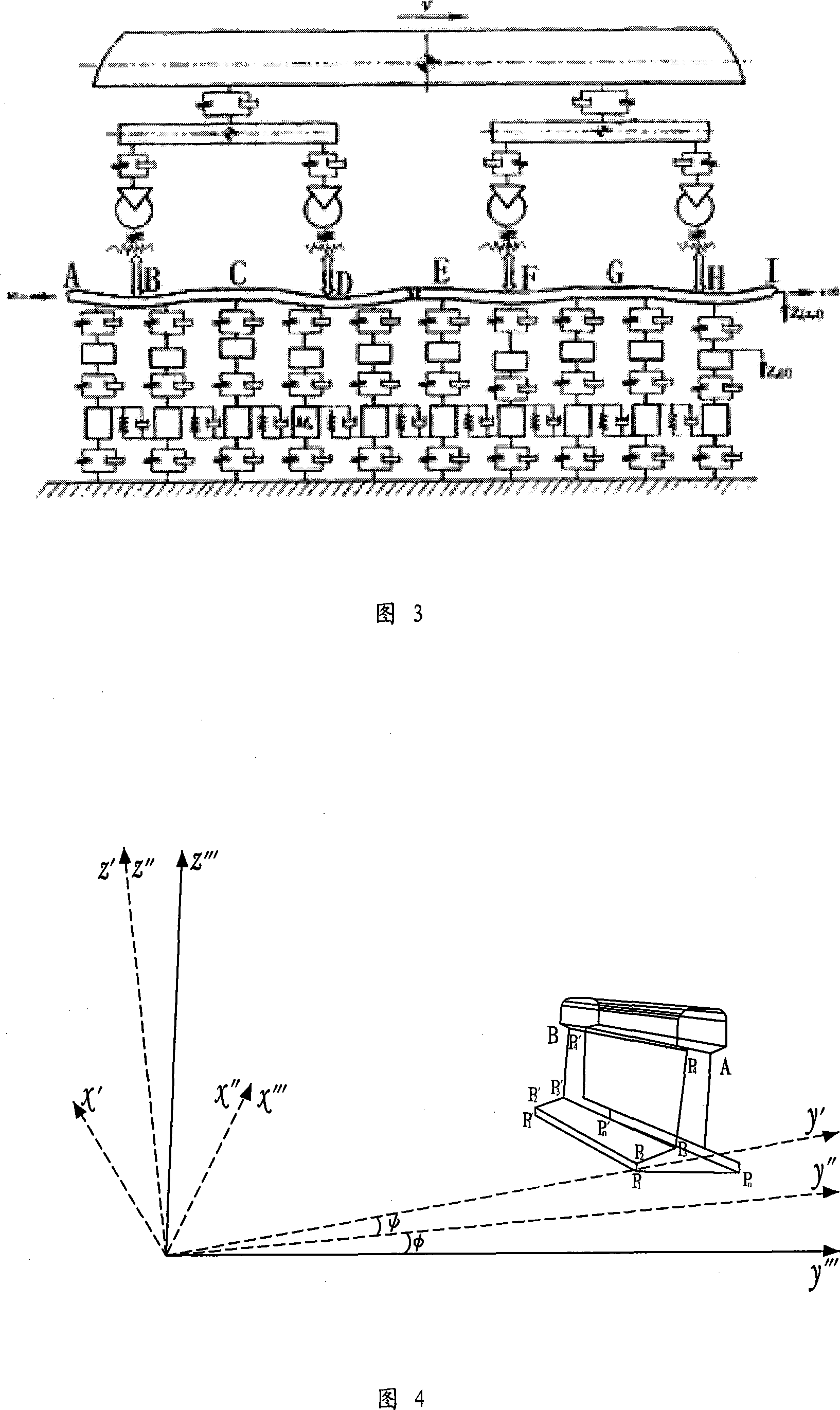

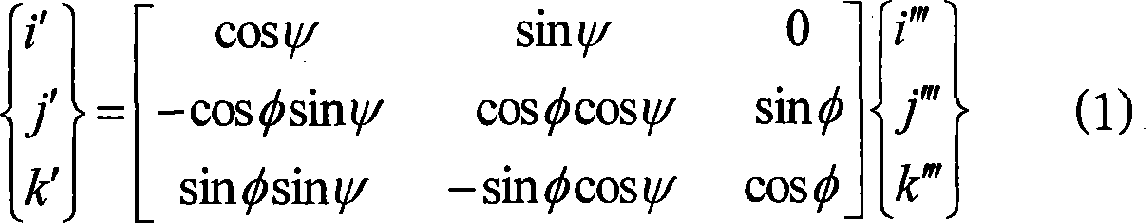

Railway track system dynamic performance visualized emulation method

InactiveCN101122930ARealize visual simulationAvoid cumbersome complexitySustainable transportationSpecial data processing applicationsHigh integrityEngineering

Owner:SOUTHWEST JIAOTONG UNIV

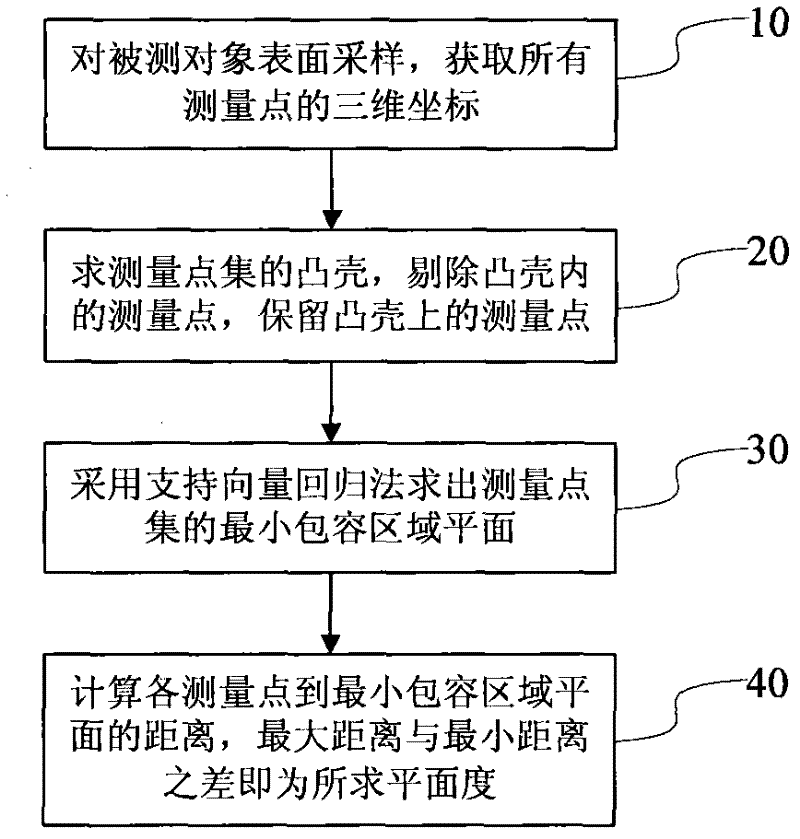

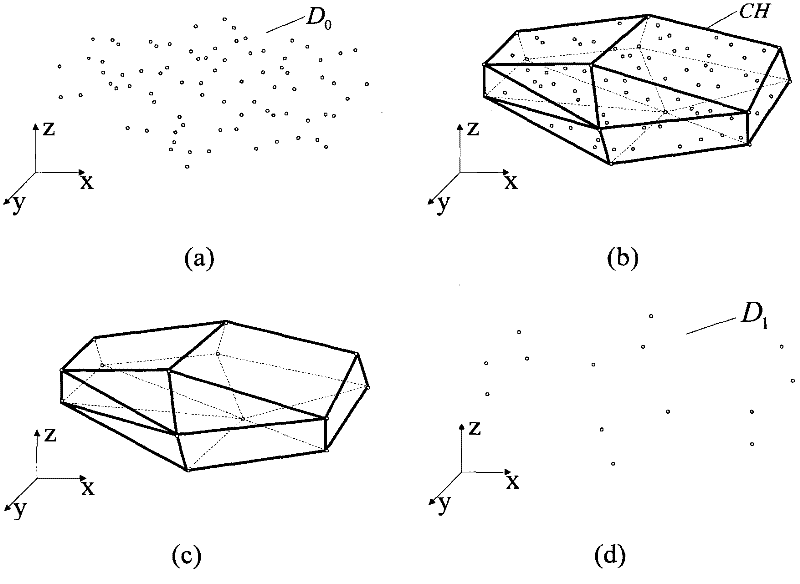

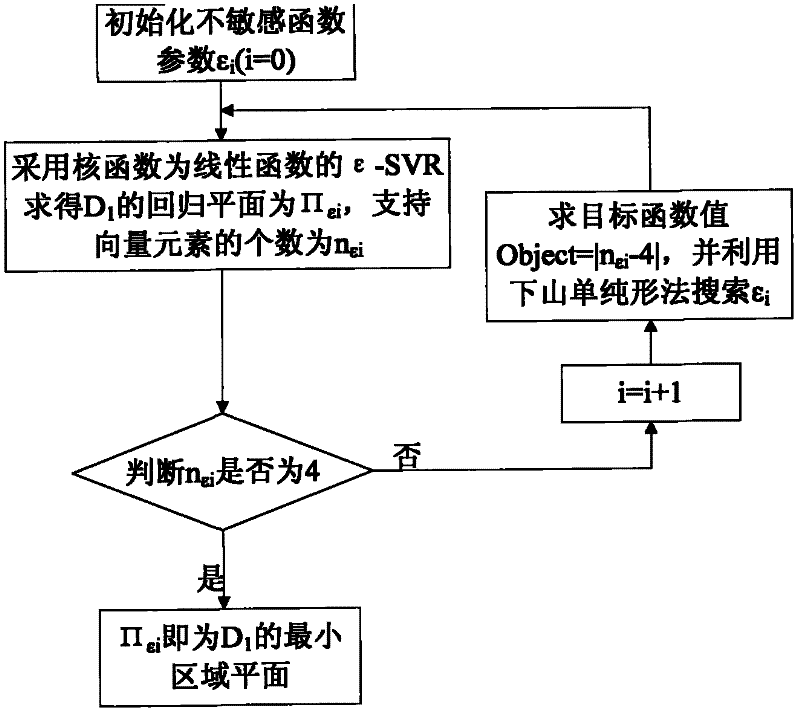

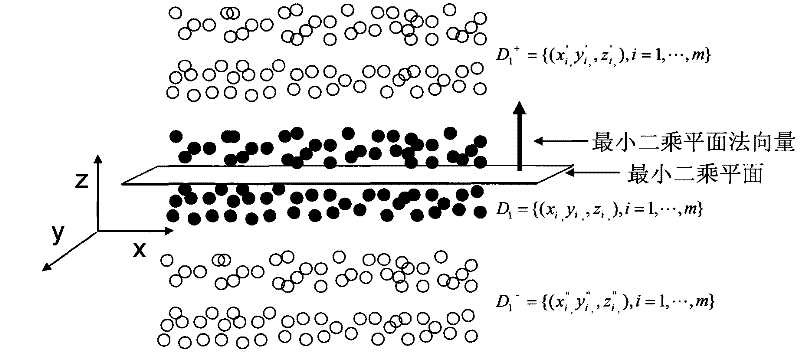

Multipoint flatness assessment method based on support vector regression

ActiveCN102445174AImprove accuracyReduce the amount of calculation dataMeasurement devicesMeasurement pointGreek letter epsilon

The invention discloses a multipoint flatness assessment method based on support vector regression, wherein the method comprises the following steps of: sampling points on the surface of a measured flat plate to acquire a three-coordinate measured value of each point; pre-processing the original measured points, measuring a three-dimensional convex housing of a point set by calculating to remove measured points in the convex housing and keep the measuring points on the convex housing; using a support vector regression method-epsilon-SVR (Support Vector Regression) to acquire a least contain area plane of the measuring point set, wherein the corresponding contain area width is the acquired flatness. With the method, the calculation data quantity in the multipoint flatness assessment can bereduced, the calculating efficiency and the degree of accuracy of the assessment result can be improved.

Owner:SOUTH CHINA UNIV OF TECH

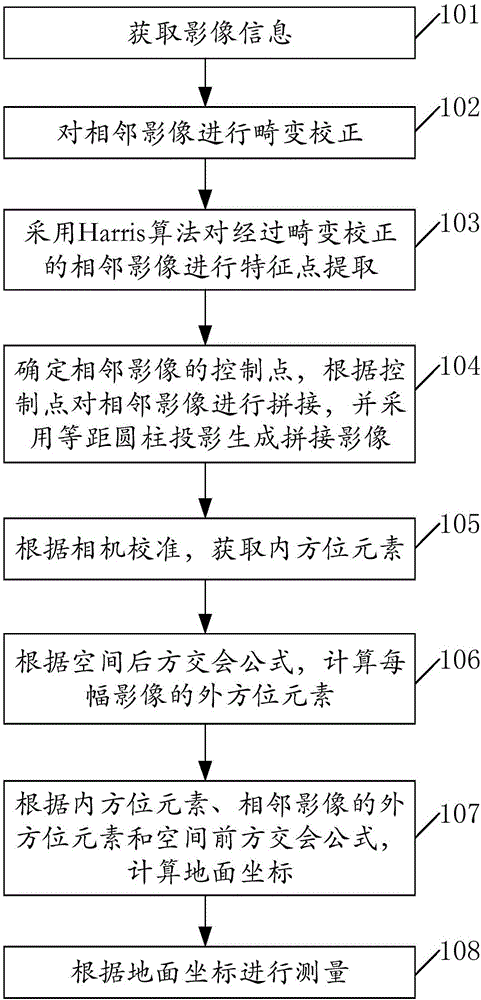

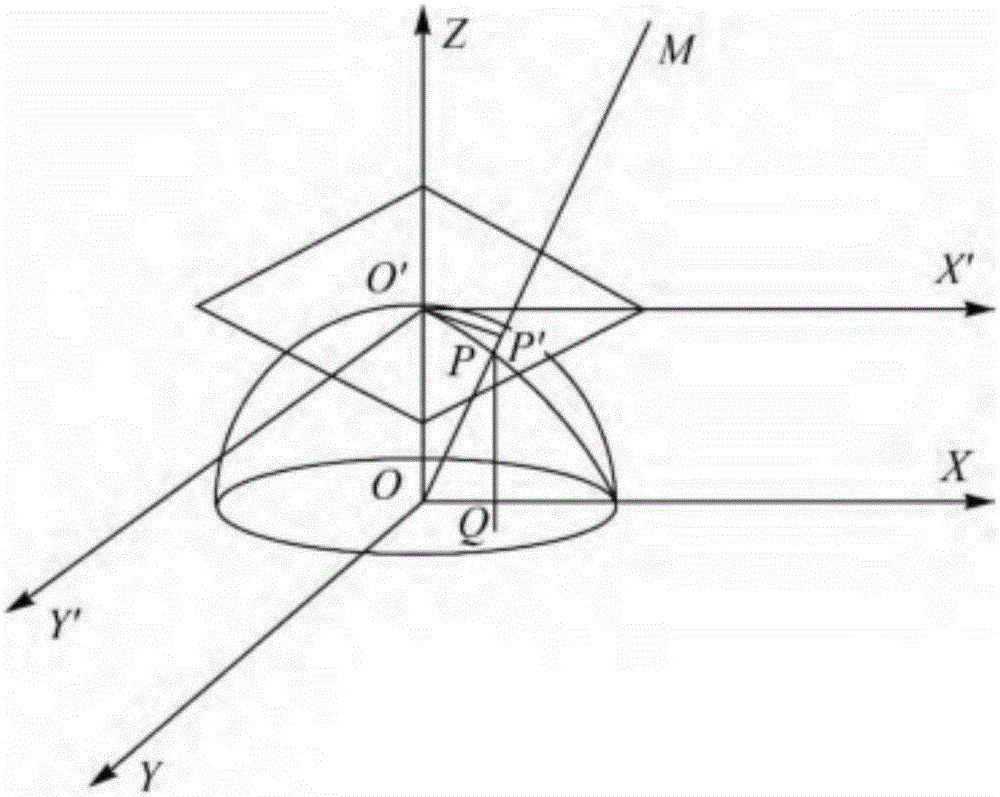

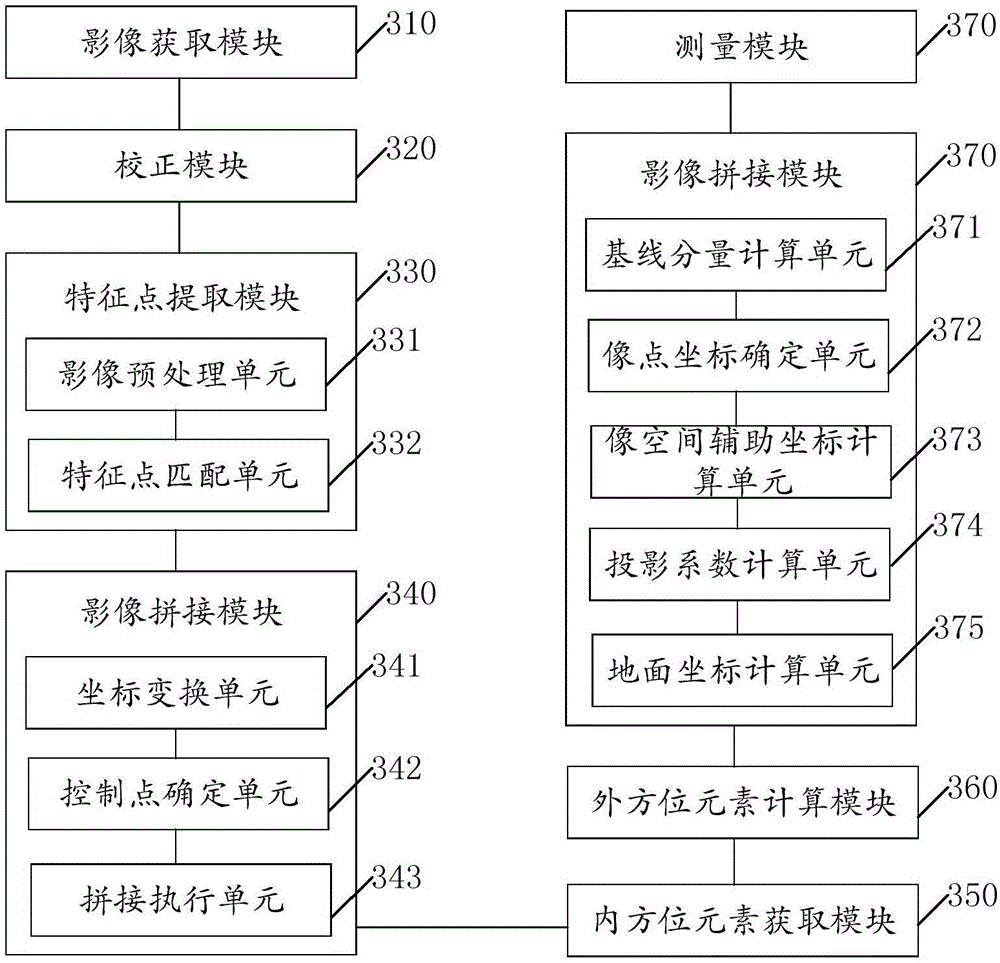

Photographing measurement method and device

InactiveCN106352855AReduce the amount of calculation dataEasy to handleOptical rangefindersGeometric image transformationPoint cloudDistortion correction

The invention relates to the technical field of photographing measurement and disclsoes a photographing measurement method and device. The photographing measurement method comprises: acquiring image information; carrying out distortion correction on adjacent images; carrying out feature point extraction on the adjacent images subjected to the distortion correction; determining control points of the adjacent images; splicing the adjacent images according to the control points; adopting equal-distance cylinder projection to generate a spliced image; calibrating according to a camera and acquiring elements of interior orientation; according to a space resection equation, calculating elements of exterior orientation of each image; according to the elements of interior orientation, the elements of exterior orientation of the adjacent images and a space intersection equation, calculating ground coordinates; measuring the ground coordinates. The photographing measurement method and device have the advantages of small calculation data quantity, simple treatment and relatively high precision; the camera does not need to be rotated by a camera cloud deck; real three-dimensional coordinates of any measureable point in a panorama can be solved through one time of photographing and a point cloud is generated, so that measurement of distances, slopes, areas and the like can be carried out.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

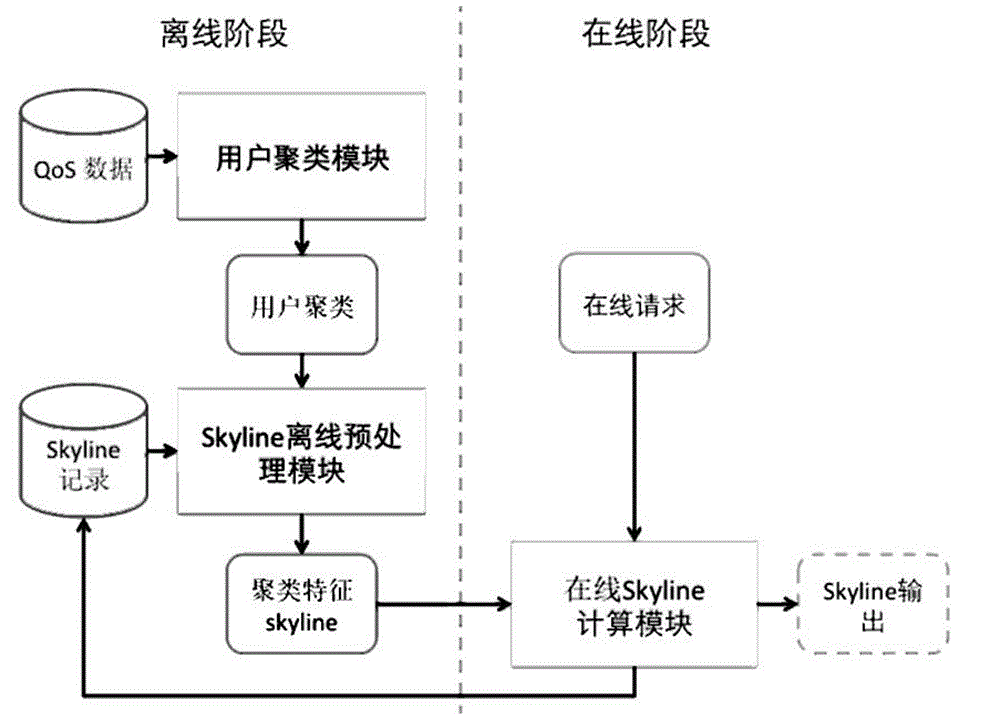

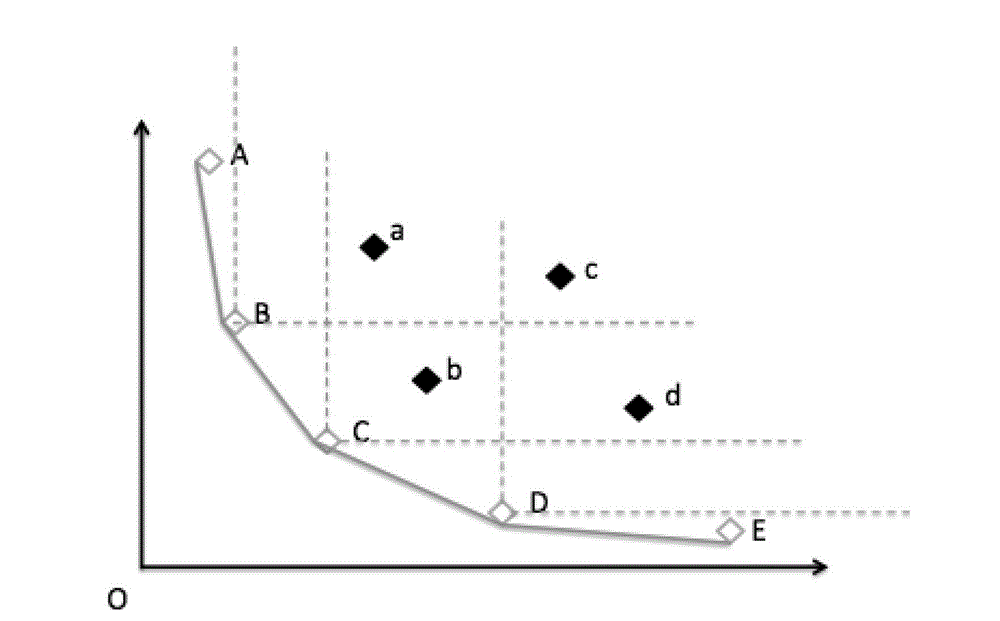

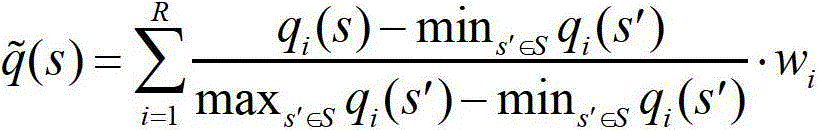

Sky line online calculation method based on user clustering

ActiveCN103150336AReduce consumptionImprove execution efficiencySpecial data processing applicationsComputing MethodologiesQuality of service

The invention discloses a sky line online calculation method based on user clustering. The sky line online calculation method comprises the following steps of: (1) gathering users with similar QoS (Quality of Service) through user clustering, and substituting for personal characteristics of each user by using common characteristics of clustering to effectively reduce the data calculating volume, converting a mode of carrying out offline processing on all the users into a mode of carrying out offline processing on each cluster to improve the offline calculation efficiency, greatly reduce the storage space consumption and improve the enablement of a system; (2) dividing a calculation process into an offline module and an online module, carrying out a great quantity of complex calculations in the offline module to effectively improve the execution efficiency of an online algorithm; and (3) predicting an individual sky line by using a group characteristic sky line to obtain a prediction result, wherein on one hand, the prediction result is returned as a result when the requirement on precision is not high, and on the other handle, the prediction result can be corrected on the predicted sky line when an accurate sky line needs to be solved, and therefore the calculation process can be simplified.

Owner:ZHEJIANG UNIV

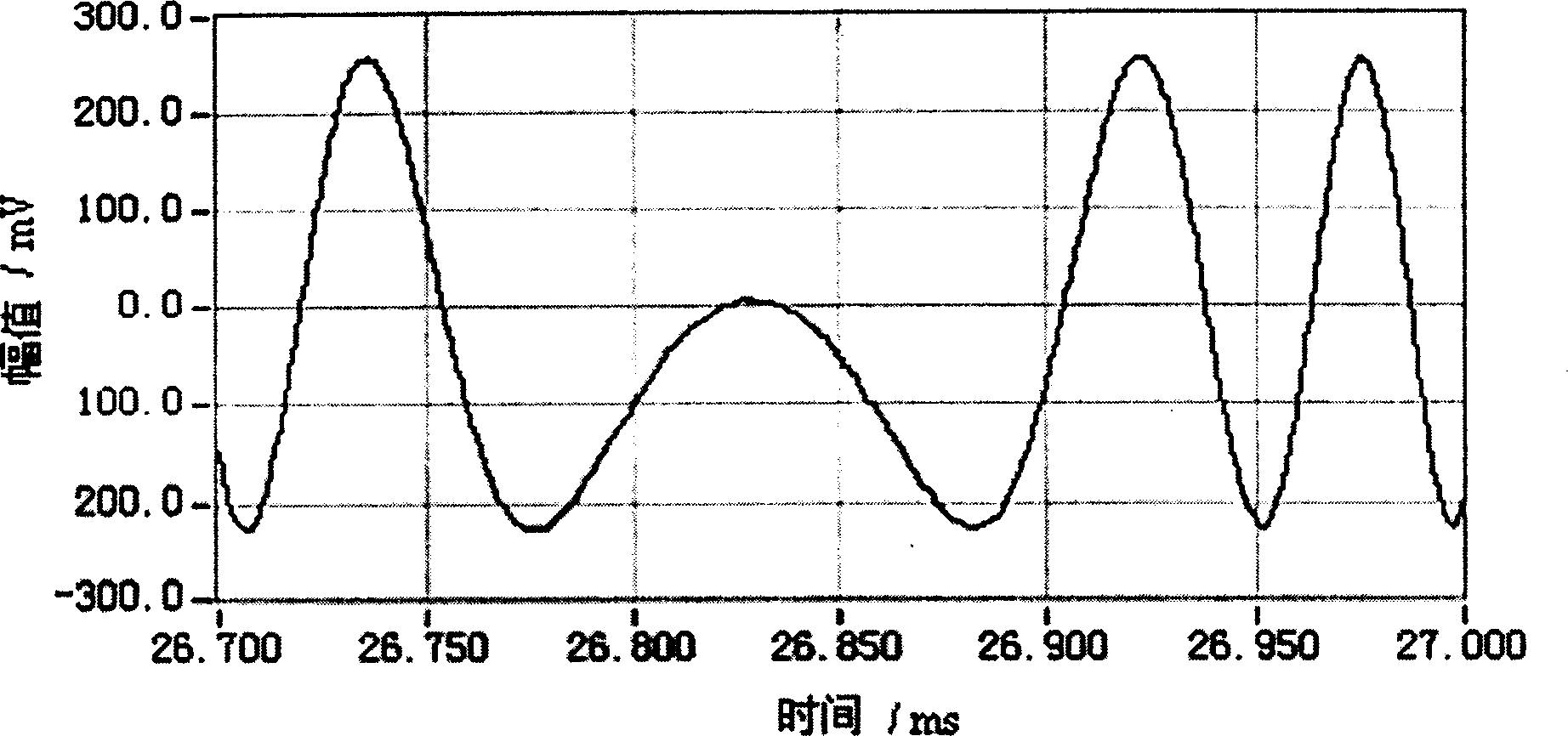

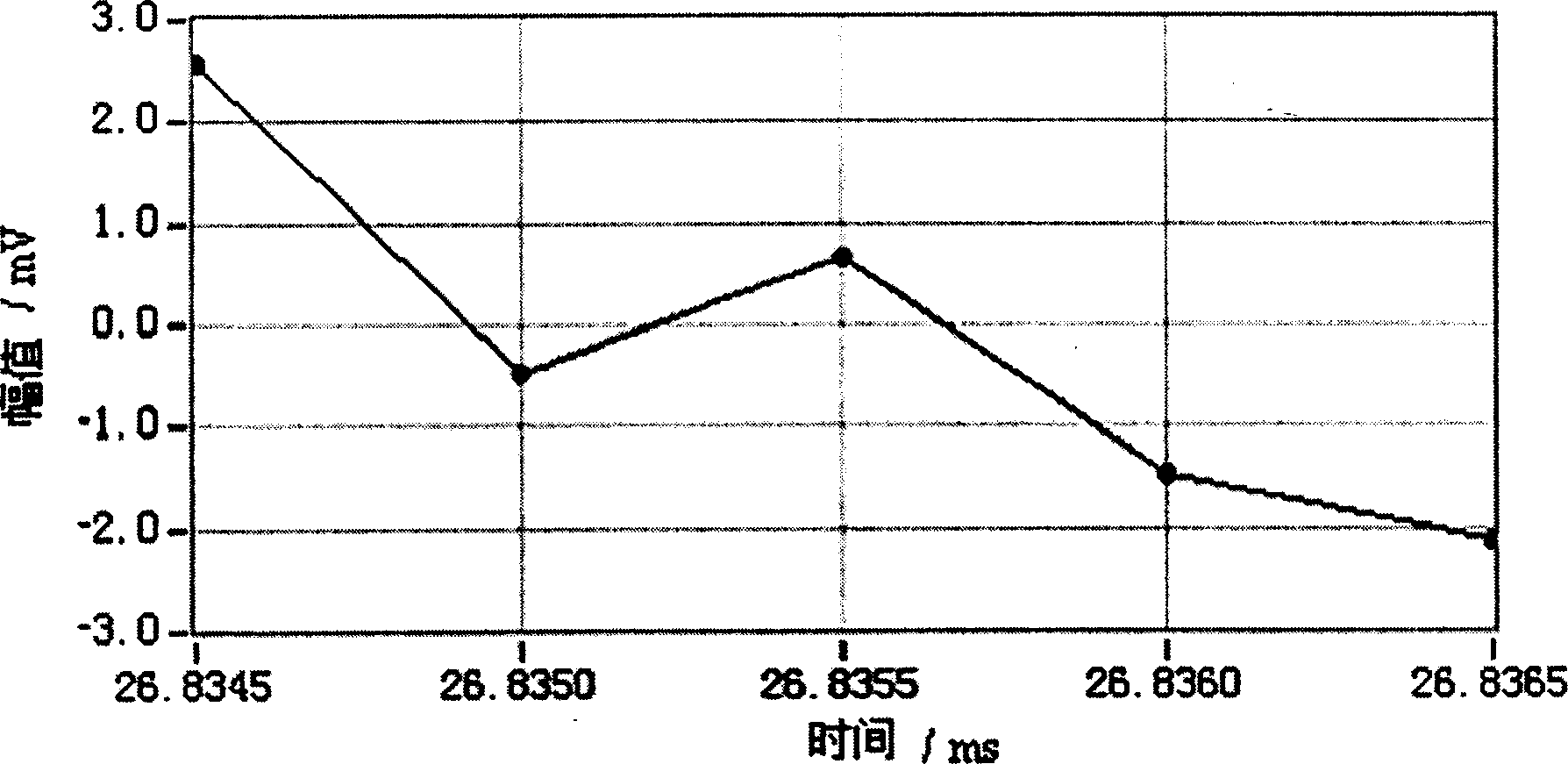

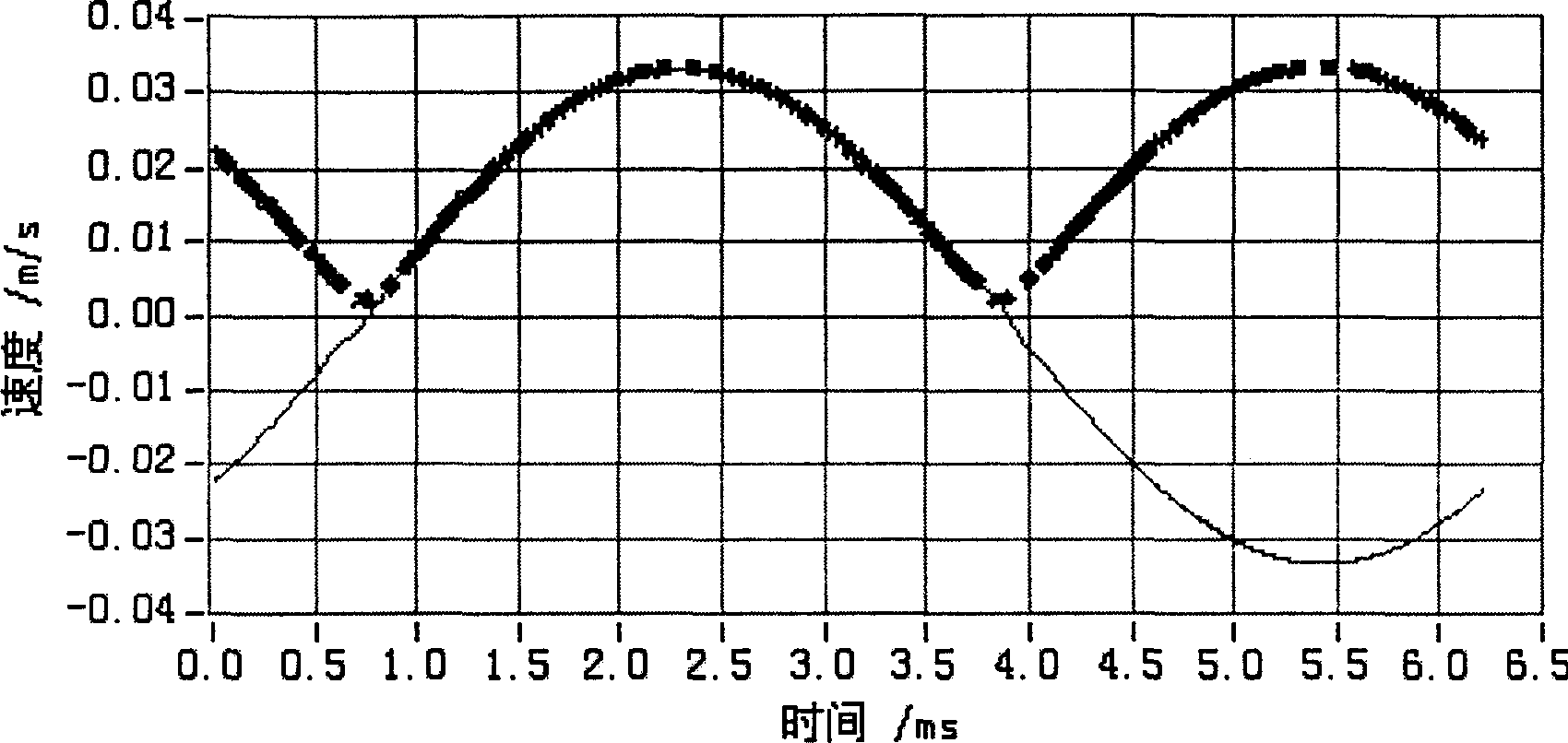

Calibration measurement method and system for single-frequency steady-state sine machinery vibrating amplitude phase characteristic

InactiveCN1811355AEliminate repeated zero crossingsAdd calculation stepsSubsonic/sonic/ultrasonic wave measurementTesting/calibration of speed/acceleration/shock measurement devicesInterval methodData acquisition

The present invention belongs to the field of metering measurement technology, in the concrete, it relates to a calibration measurement method of vibration and its calibration measurement system. Said invention provides an improved homodyne time interval method based on general Michelson laser interferometer, said method can reduce the computing quantity due to noise signal and can simplify zero-crossing point position judgment. The invented calibration measurement system includes Michelson laser interferometer, computer and synchronous data acquisition card. Said invention can be used for calibrating work of acceleration sensor.

Owner:NAT INST OF METROLOGY CHINA

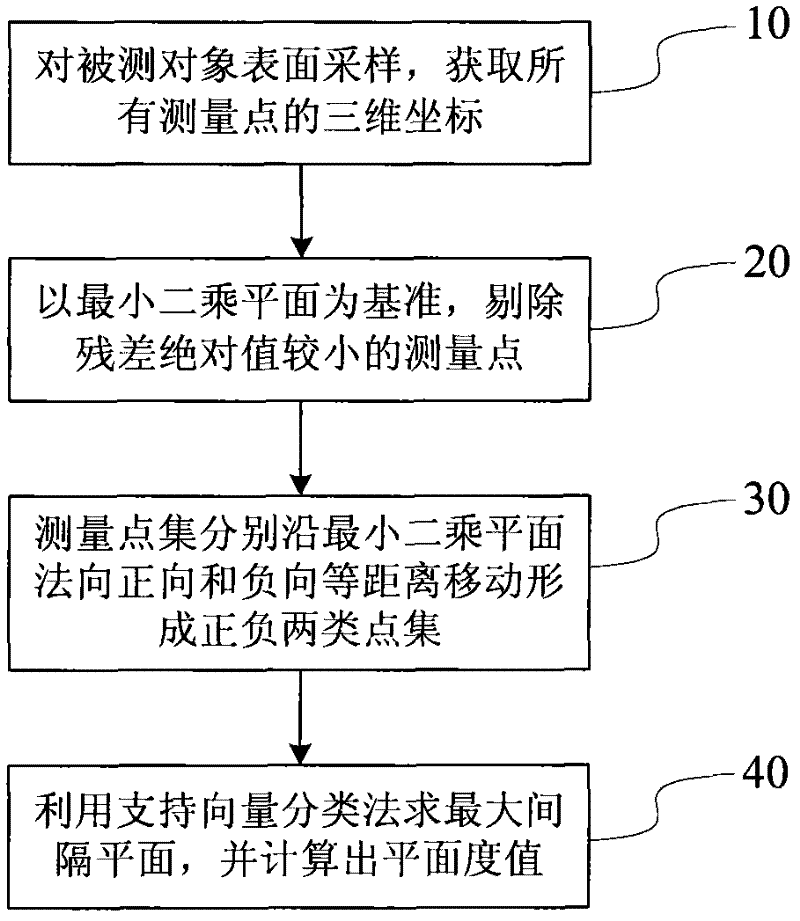

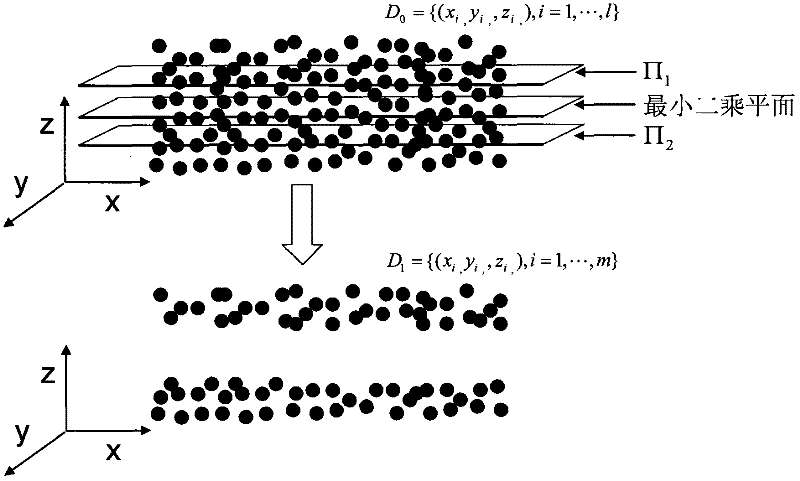

Multi-measuring-point planeness evaluation method based on support vector classification

ActiveCN102506805AReduce the amount of calculation dataImprove computing efficiencyMeasurement devicesLeast squaresPositive direction

The invention discloses a multi-measuring-point planeness evaluation method based on support vector classification. The method comprises the following steps: sampling points on a tested surface to obtain a three-dimensional coordinate measurement value of each point; calculating a least square surface corresponding to a measurement point set; with the least square surface as a reference, removing measurement points with a small residual absolute value; moving measurement points with a big residual absolute value for the same distance respectively along the positive direction and the negative direction of the normal direction of the least square surface to form a linearly separable positive point set and negative point set; calculating the maximum interval plane of the positive point set and the negative point set with a linearly classified support vector machine method; and calculating a planeness value according to the plane. According to the multiple-measuring-point planeness evaluation method, the calculation data amount in the multiple-measuring-point planeness evaluation can be reduced and the calculation efficiency and the accuracy of an evaluation result are obviously improved.

Owner:SOUTH CHINA UNIV OF TECH

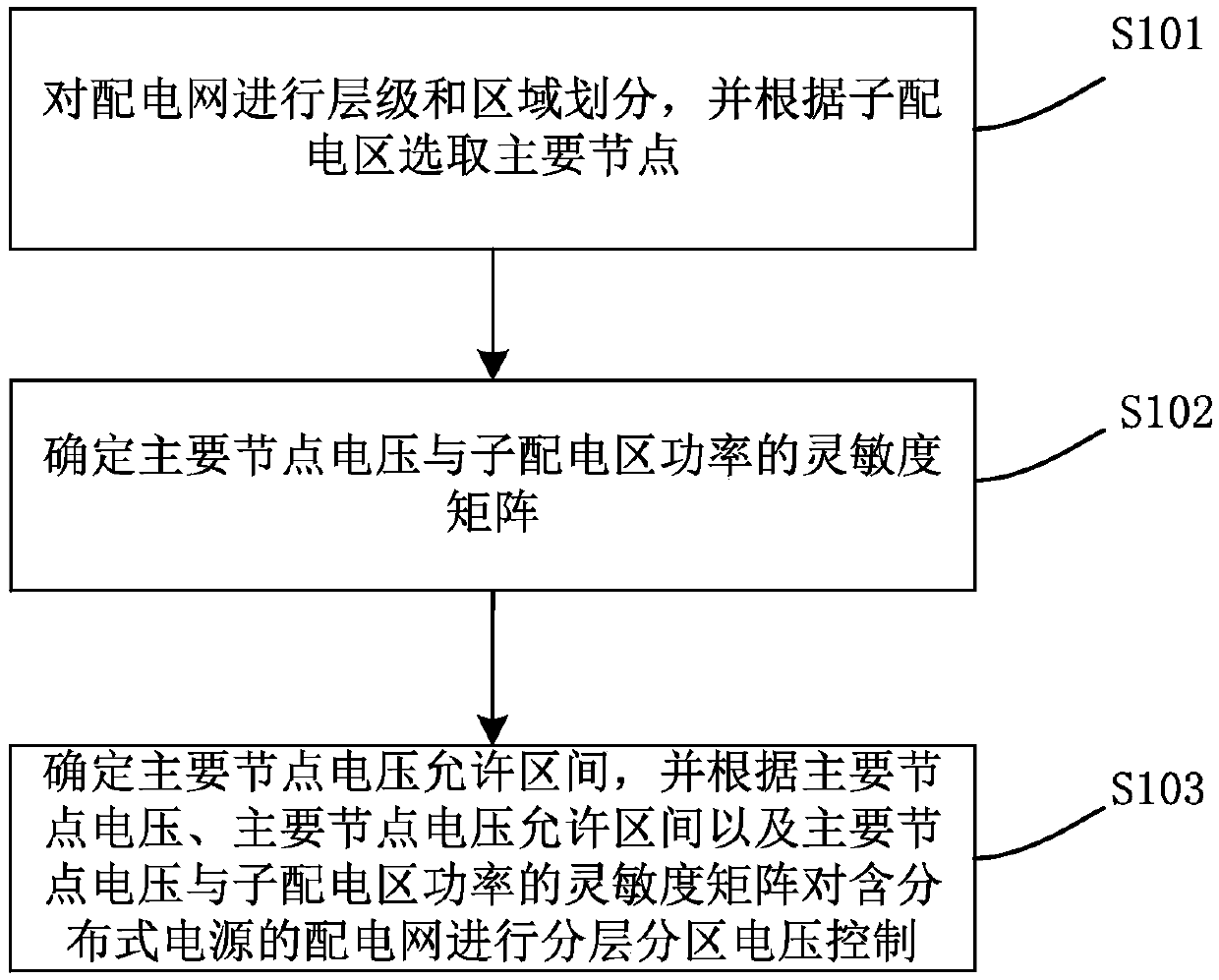

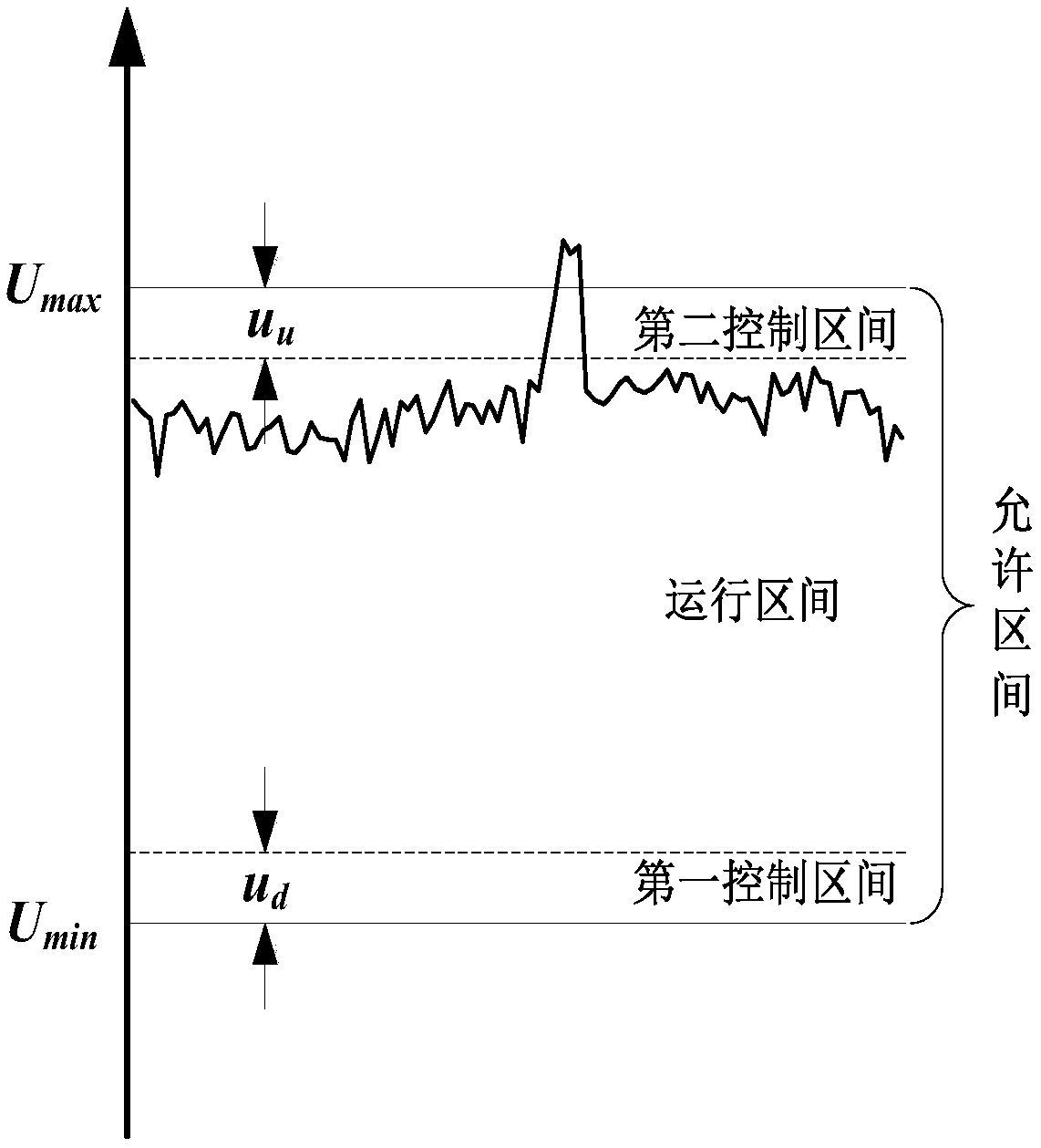

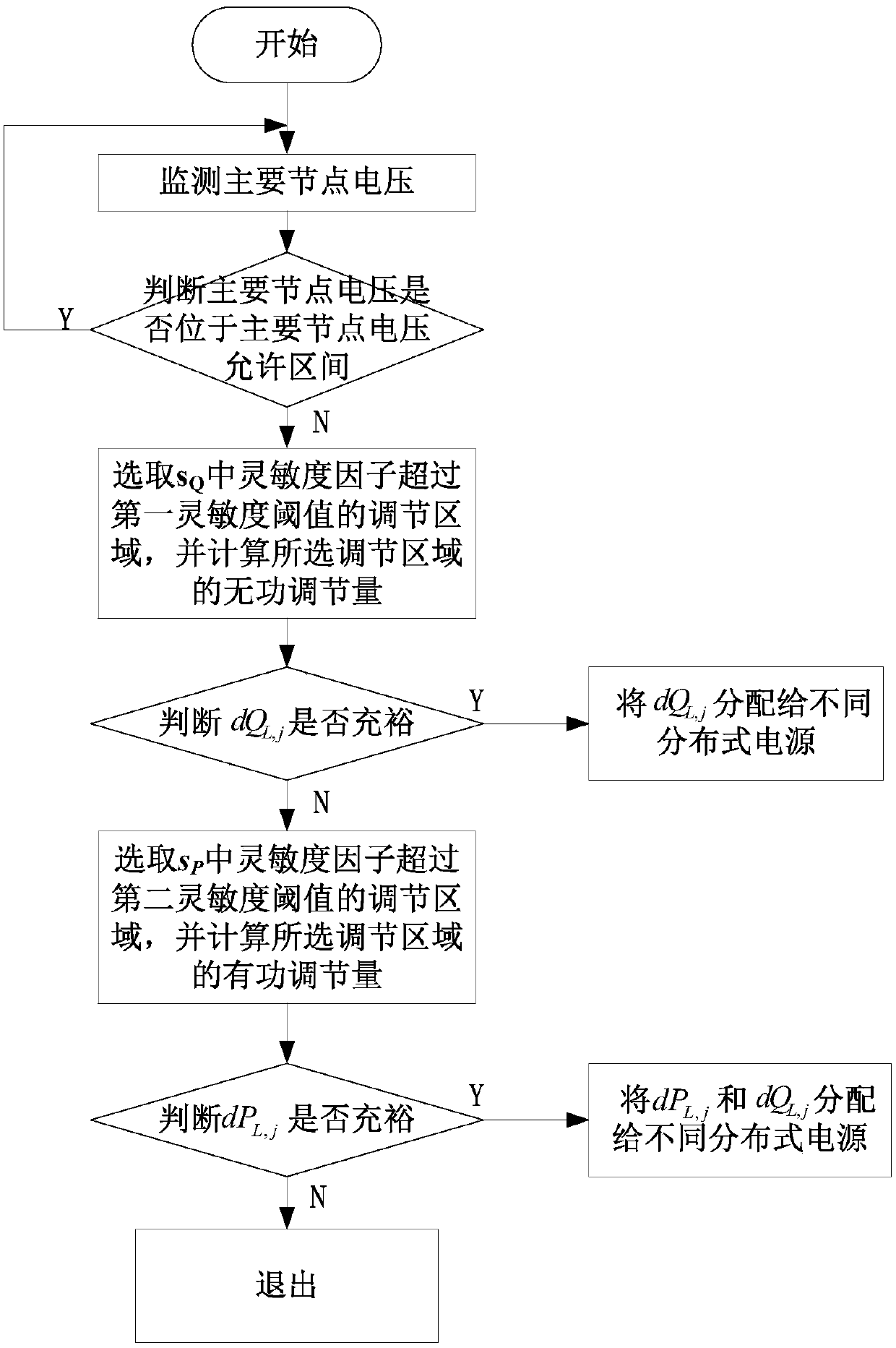

Voltage control method and device for power distribution network provided with distributed power source

ActiveCN108683193AFlexible and efficient useImprove voltage control capabilitySingle network parallel feeding arrangementsAc network voltage adjustmentControl systemEngineering

The invention provides a voltage control method and device for a power distribution network provided with a distributed power source. The method includes the following steps that: the main nodes of each sub power distribution area in the power distribution network are obtained; the sensitivity matrix of the voltages of the main nodes and the power of the sub power distribution areas is determined;and a main node voltage allowable interval is determined, and voltage control is performed on the power distribution network provided with the distributed power source. According to the voltage control method and device of the invention, the optimized scheduling means of the distributed power source is provided; the flexible and efficient utilization of the distributed power source can be realized; a voltage quality requirement of the connection of a large-scale distributed power source into the power distribution network can be satisfied; the main nodes are adopted as the objects of voltagecontrol, so that the amount of calculation data on a global layer is decreased, and calculation efficiency can be effectively improved; and the frequent action of a control system can be avoided; andthe voltage control capability of the power distribution network with the distributed power source is improved; and the operational safety of the power distribution network with the distributed powersource is ensured.

Owner:CHINA ELECTRIC POWER RES INST +1

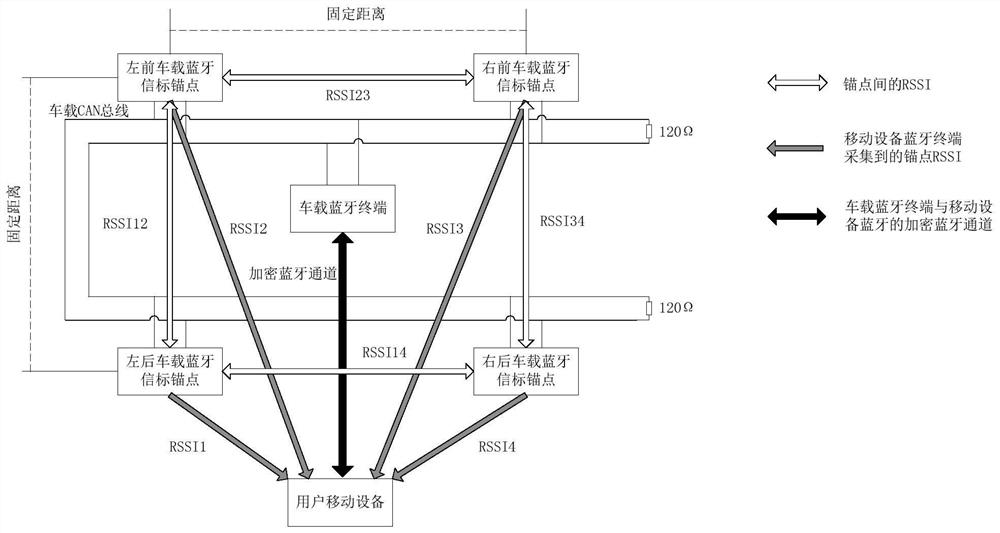

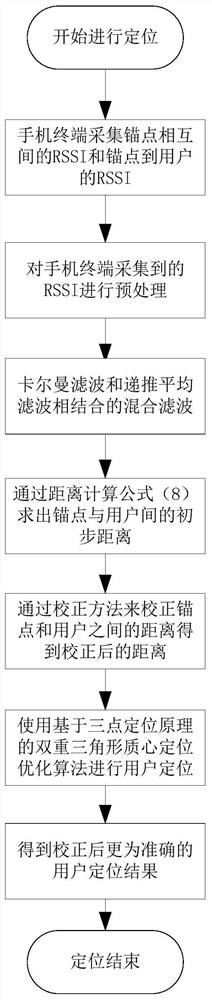

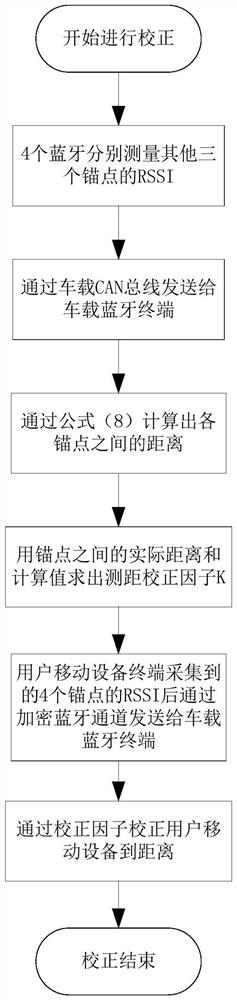

Vehicle-mounted Bluetooth positioning system and positioning method thereof

ActiveCN111818636AAchieve correctionReal-time positioningParticular environment based servicesIn-vehicle communicationComputer hardwareIn vehicle

The invention discloses a vehicle-mounted Bluetooth positioning system and a positioning method thereof, and relates to the field of Bluetooth positioning, the positioning system comprises a user mobile device terminal, a vehicle-mounted Bluetooth terminal and four Bluetooth beacon anchor points arranged in a rectangular shape on a vehicle body; the Bluetooth beacon anchor point and the vehicle-mounted Bluetooth terminal are connected to a vehicle-mounted network. The positioning method comprises the following steps of enabling Bluetooth beacon anchor points to respectively send RSSI (ReceivedSignal Strength Indicator) outwards, collect other RSSI and send the RSSI to a user mobile equipment terminal; after the user mobile equipment terminal collects RSSI of the Bluetooth beacon anchor point, filtering RSSI data; calculating the calculation distances between the anchor points and between the anchor points and the user mobile equipment terminal, calculating a correction factor according to the actual distances between the anchor points, and correcting the calculation distances; and establishing a coordinate system, and performing positioning by using a double-triangle centroid positioning algorithm to obtain the position of the user mobile device. The system and the method have the advantages of being simple in hardware topological structure, small in required calculation datasize, high in real-time performance, small in external environment influence, accurate in positioning and the like.

Owner:HARBIN INST OF TECH AT WEIHAI +1

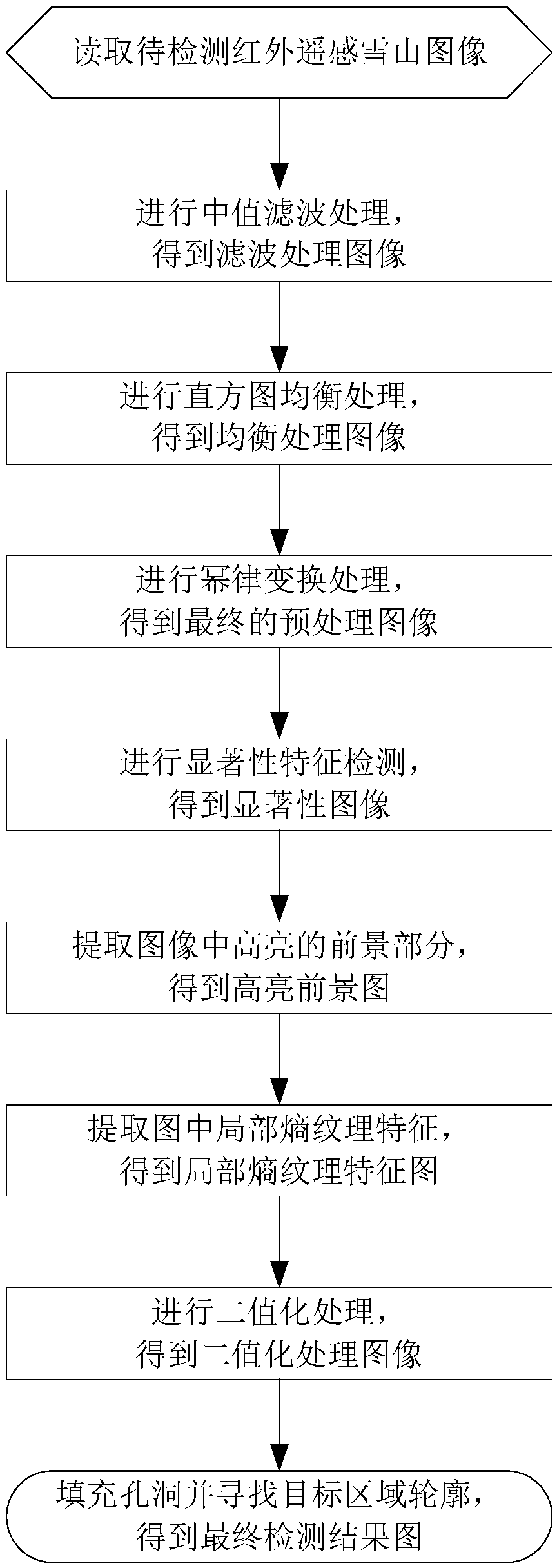

Snow mountain detection method based on infrared remote sensing image

InactiveCN108765406ARealize detectionReduce false detection rateImage analysisScene recognitionInfrared remote sensingImaging quality

The invention discloses a snow mountain detection method based on an infrared remote sensing image, and belongs to the field of remote sensing image processing. The method includes the following steps: Step 1, reading an infrared remote sensing snow mountain image to be detected, and performing saliency feature detection to obtain a saliency image; Step 2, extracting a highlighted foreground partin the saliency image to obtain a highlighted foreground image; Step 3, extracting local entropy texture features in the highlighted foreground image to obtain a local entropy texture feature image; and Step 4, performing binarization processing on the local entropy texture feature image, filling holes and searching the outline of a target region to obtain a final detection result image. The snowmountain detection method based on an infrared remote sensing image solves the problem that an existing snow mountain detection method has a relatively high requirement for image quality, relatively large calculation data volume, is not beneficial to the real-time monitoring of the snow mountain, and has relatively high false detection probability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

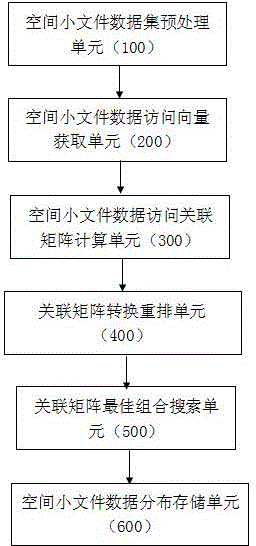

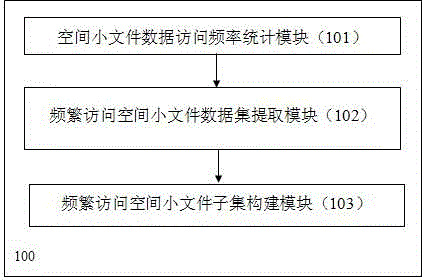

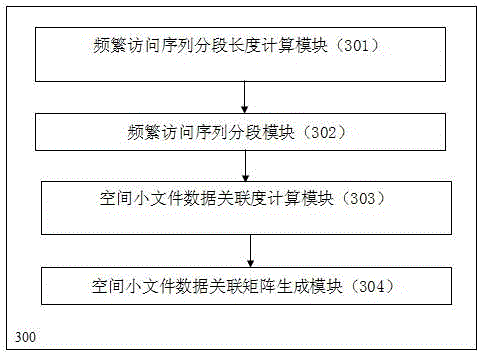

Space small file data distribution storage method and system based on access log information

InactiveCN104573082AImprove service capabilitiesImprove parallel access performanceInput/output to record carriersSpecial data processing applicationsData setSorting algorithm

The invention provides a space small file data distribution storage method and system based on access log information. The method includes: dividing a space small file data set into a frequently-accessed sub-set and a non-frequently-accessed sub-set, extracting the access sequence of the frequently-accessed space small file sub-set, calculating the association degree of each frequently-accessed space small file datum, and using the values of the association degrees to form an association matrix; performing magnitude conversion on each value in the association matrix, using an RCM sorting algorithm to rearrange the values, then outputting the values, using a local approximation search method to search for the optimal combination of the rearranged association matrix, using the optimal combination to perform distributed storage on the frequently-accessed space small data, and separately storing the non-frequently-accessed space small file data according to space position neighboring relations.

Owner:WUHAN UNIV

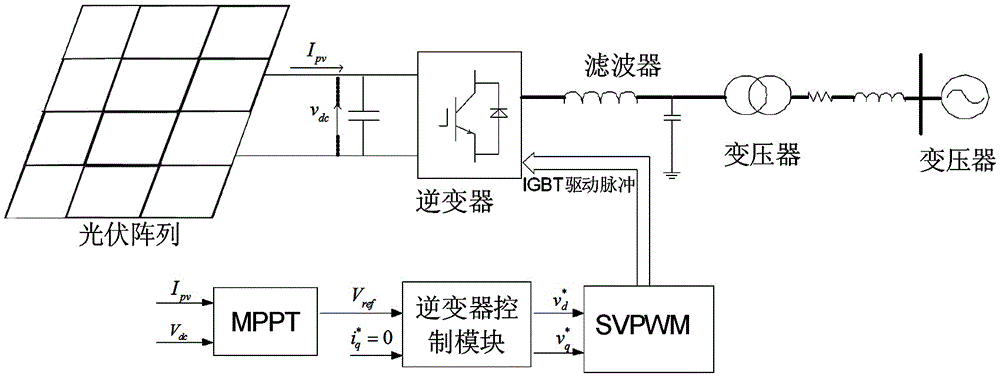

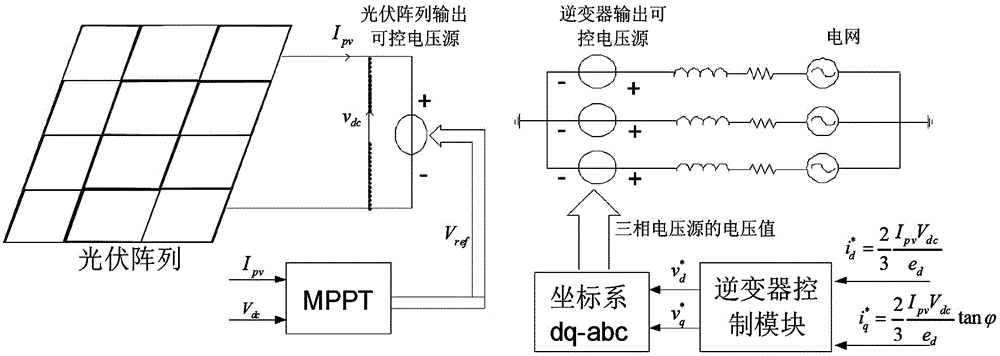

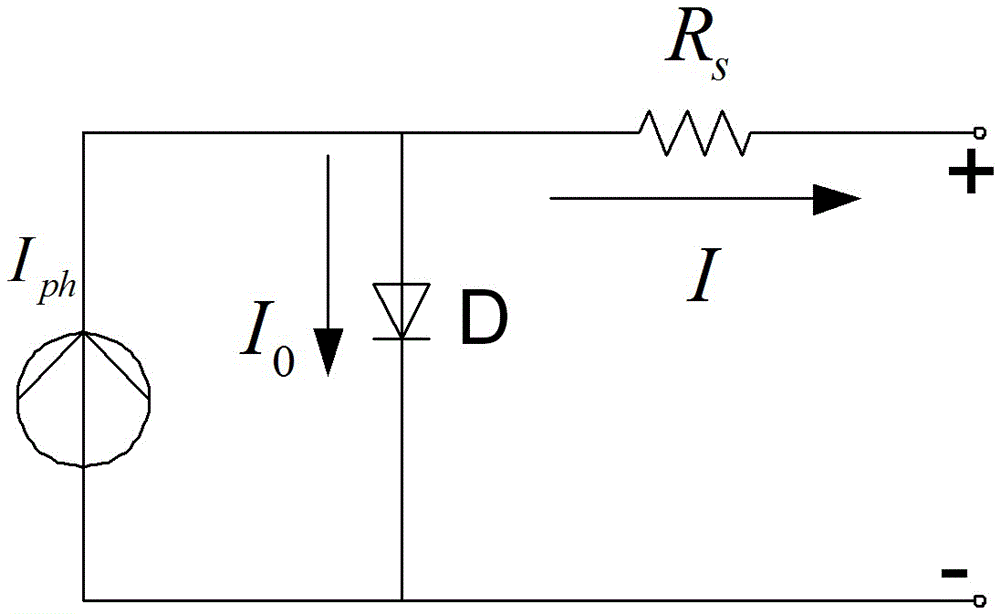

Distributed photovoltaic power generation system equivalent simulation model based on PSCAD (Power System Computer Aided Design)/EMTDC (Electromagnetic Transient Including DC)

ActiveCN105608244AReduce the amount of calculation dataReduced simulation timeSpecial data processing applicationsElectromagnetic shieldingVoltage source

The invention belongs to the technical field of distributed photovoltaic power generation, particularly relates to a distributed photovoltaic power generation system equivalent simulation model based on PSCAD (Power System Computer Aided Design) / EMTDC (Electromagnetic Transient Including DC), and is suitable for simplifying a distributed power generation system simulation model in the PSCAD / EMTDC and carrying out equivalent simulation on large distributed power station in the PSCAD / EMTDC. The distributed photovoltaic power generation system equivalent simulation model comprises a photovoltaic array module, a photovoltaic array controllable voltage source module, an inverter controllable voltage source module, a MPPT (Maximum Power Point Tracking) control module of the photovoltaic array controllable voltage source module, a control module of the inverter controllable voltage source module, a two-phase rotating coordinate system to three-phase stationary coordinate system conversion module and an inverter side filtering inductance and equivalent power grid model, wherein the photovoltaic array module, the inverter controllable voltage source module and the inverter controllable voltage source module are connected through the inverter side filtering inductance and equivalent power grid model. A calculation data size can be reduced, simulation time is shortened, and calculation speed and efficiency can be obviously improved.

Owner:STATE GRID CORP OF CHINA +2

Electromagnetic spectrum map construction method and device, computer equipment and storage medium

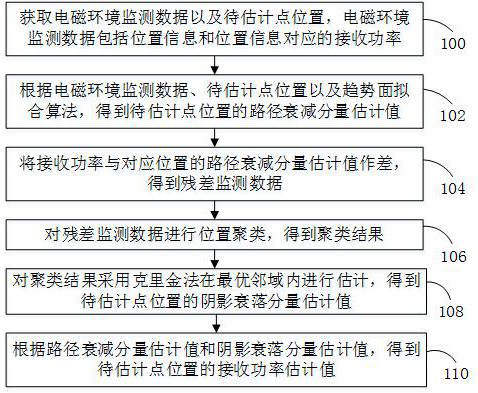

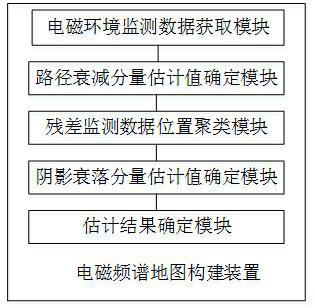

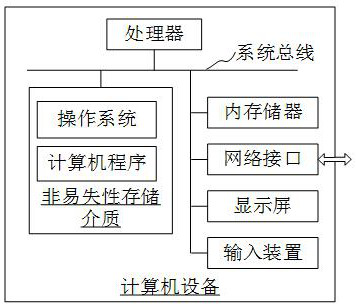

ActiveCN112698112AImprove build precisionBuild fastCharacter and pattern recognitionElectromagentic field characteristicsPrior informationElectromagnetic spectrum

The invention relates to an electromagnetic spectrum map construction method and device, computer equipment and a storage medium. The method comprises the following steps: acquiring monitoring data and a to-be-estimated point position, and acquiring path attenuation component estimation by using a trend surface fitting algorithm; subtracting the monitoring data from the path attenuation component estimation value of the corresponding position, performing position clustering on the obtained residual monitoring data, and estimating a clustering result in an optimal neighborhood by adopting a Kriging method to obtain shadow fading component estimation; and obtaining an estimation result according to the path attenuation component and the shadow fading component. Electromagnetic spectrum map construction is decomposed into estimation of path attenuation and shadow fading components, so that the electromagnetic spectrum map construction precision is effectively improved; through monitoring data clustering and optimal neighborhood selection, the calculated amount is reduced under the condition of ensuring the construction precision, and the electromagnetic spectrum map construction speed is effectively improved; and the method does not need prior information such as a radiation source and a propagation model, and has good adaptability.

Owner:NAT UNIV OF DEFENSE TECH

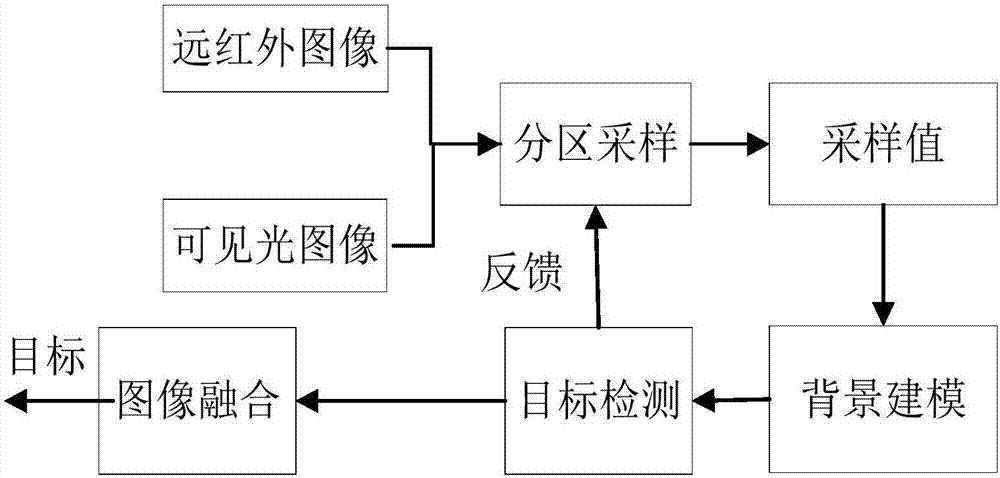

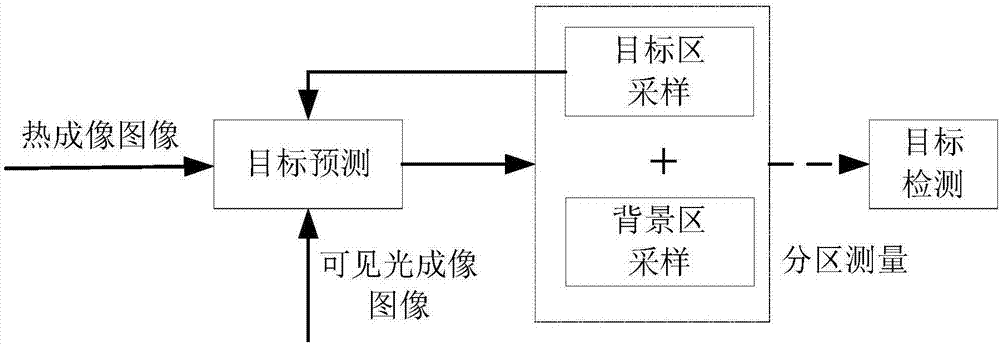

Target detection method with visible light and far infrared rays fused

InactiveCN107423709AGood Object Detection ResultsImprove anti-interference abilityImage enhancementImage analysisFar infraredComputer vision

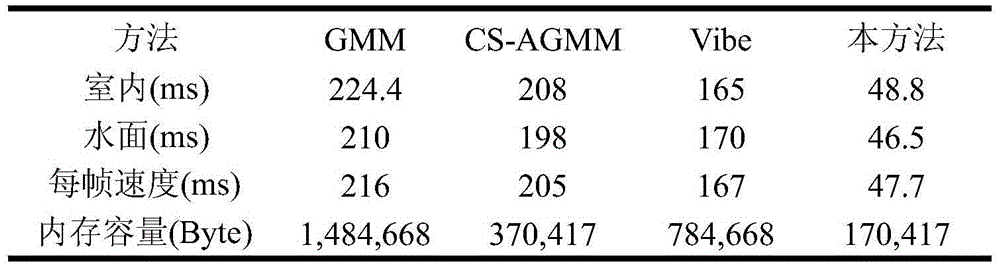

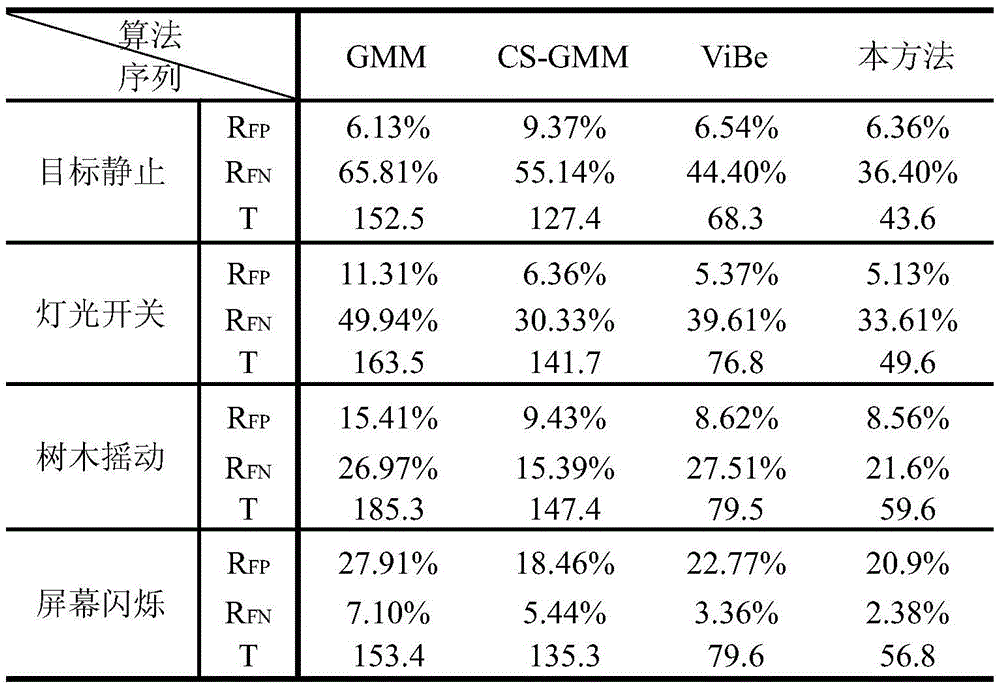

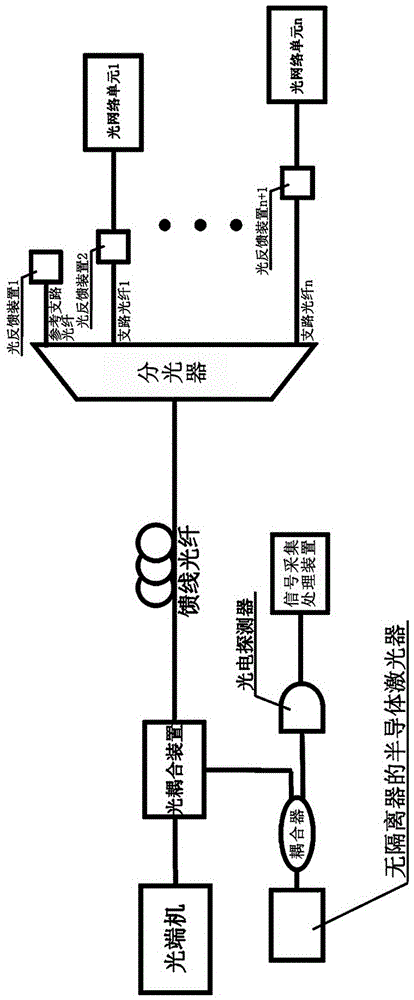

The invention discloses a target detection method with visible light and far infrared rays fused. The method comprises steps: an acquired visible image and an acquired far infrared thermal imaging image are blocked, and the obtained image blocks are converted to N*1 vectors; a mixed sampling matrix is constructed to carry out acquisition and compression on converted vectors to obtain each image block after compression; a pixel-level background modeling algorithm is adopted to detect each pixel point in each image block after compression, and a target area and a background area in the image block are determined; and the detected target image and the far infrared thermal imaging image are overlapped to obtain a target image after fusion. As the mixed sampling matrix is adopted to sample and compress the image, the calculation data amount is reduced, the learning rate is adjusted according to an area, the average calculation time is reduced, the pixel number is reduced on the whole, the background modeling time is effectively reduced, and compared with the traditional target detection algorithm, the target detection method of the invention enables the memory capacity to be reduced by three fourths and the processing time can be reduced by more than 40%.

Owner:SUZHOU INST OF TRADE & COMMERCE

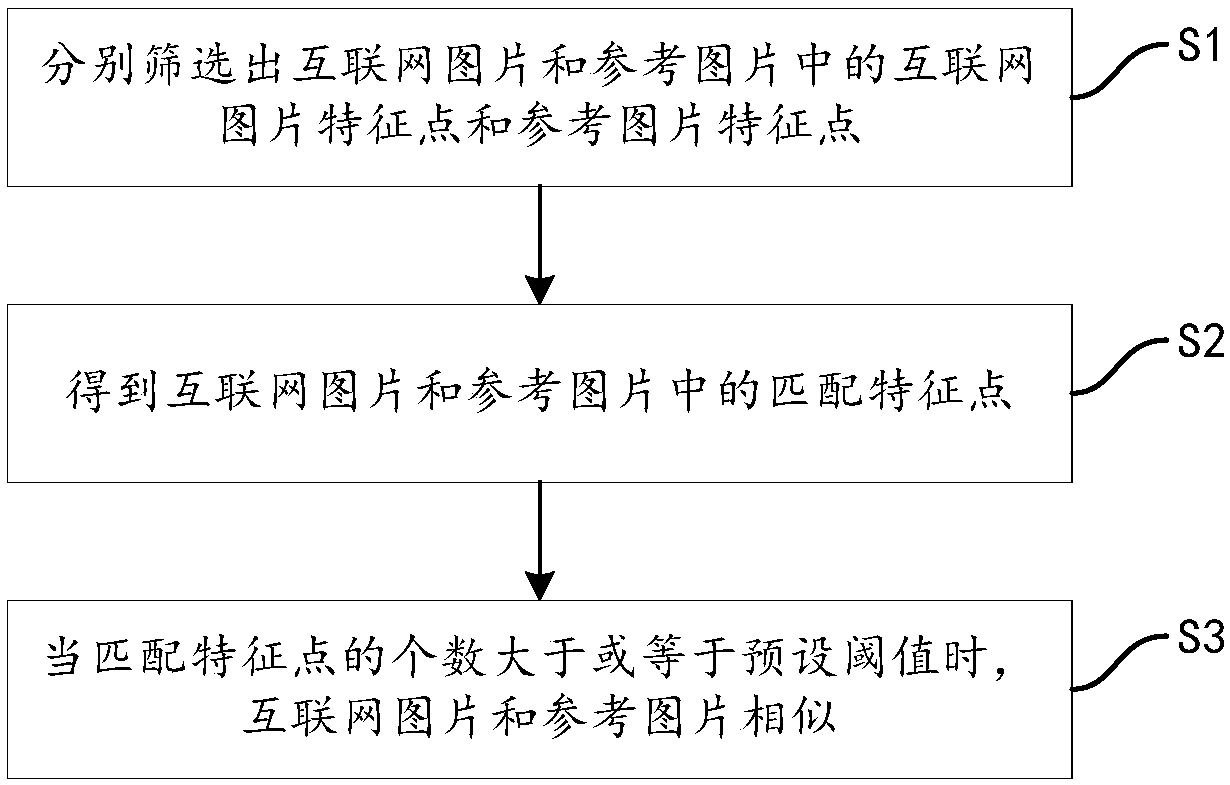

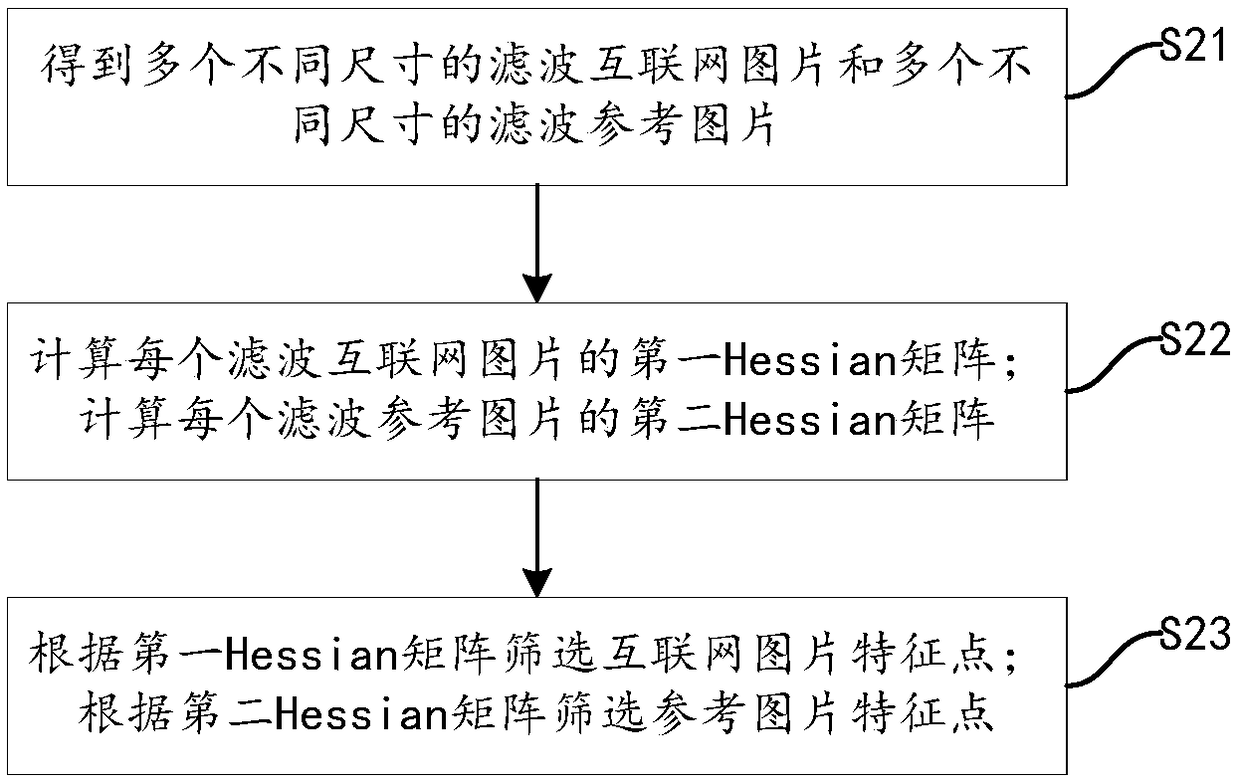

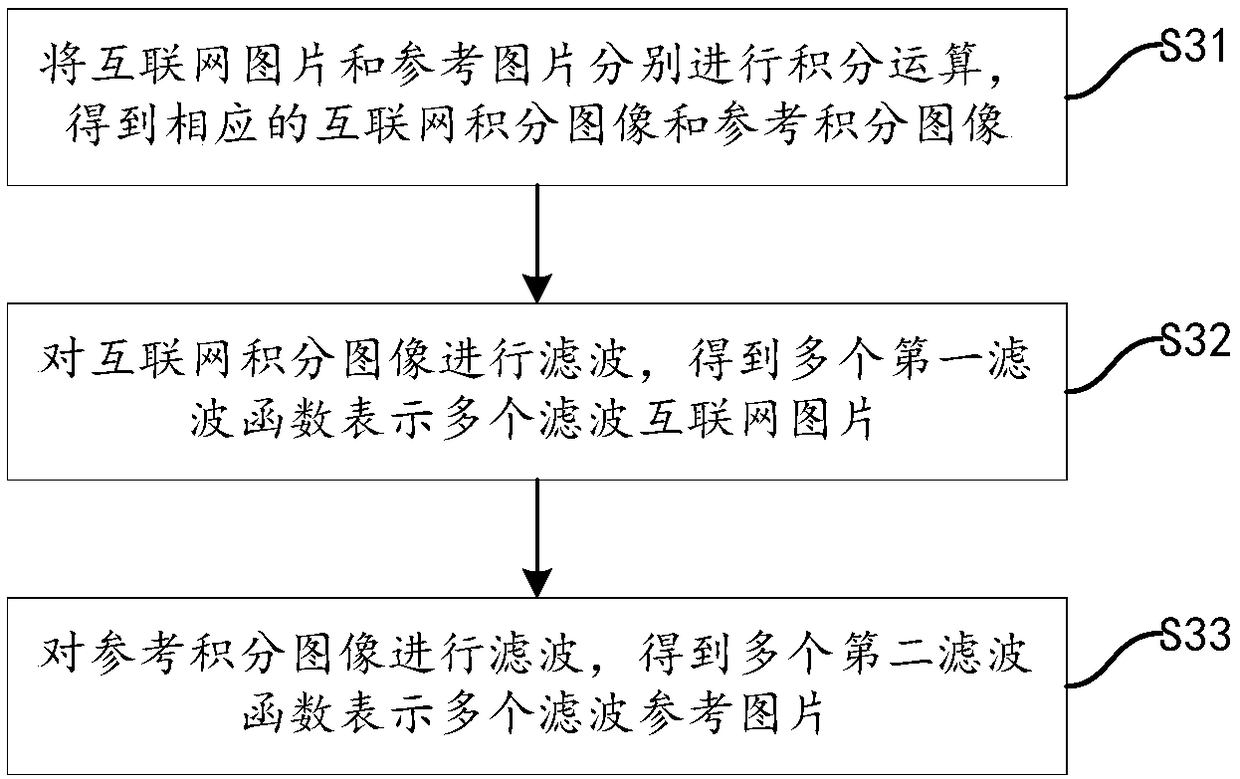

Picture similarity detecting and system

ActiveCN108960280AReduce the amount of calculation dataImprove noise immunityCharacter and pattern recognitionPattern recognitionThe Internet

The invention relates to a picture similarity detecting method and system. The detecting method comprises a step of screening out Internet picture feature points in an Internet picture and reference picture feature points in a reference picture, and a step of obtaining matched feature points in the Internet picture and the reference picture according to all Internet picture feature points and allreference picture feature points, wherein the Internet picture and the reference picture are similar to each other when the number of matched feature points is larger than or equal to a preset threshold. According to the embodiment of the present invention, by obtaining and comparing the feature points of two pictures, whether the feature points of the Internet picture and the reference picture are matched is judged, the number of matched feature points is counted, when the number of matched feature points is larger than or equal to the preset threshold, a condition that the Internet picture and the reference picture are similar to each other is confirmed, in the embodiment of the present invention, the amount of calculated data is small, the anti-noise capability is strong, and whether pictures are similar to each other is quickly identified and checked.

Owner:北京中科闻歌科技股份有限公司

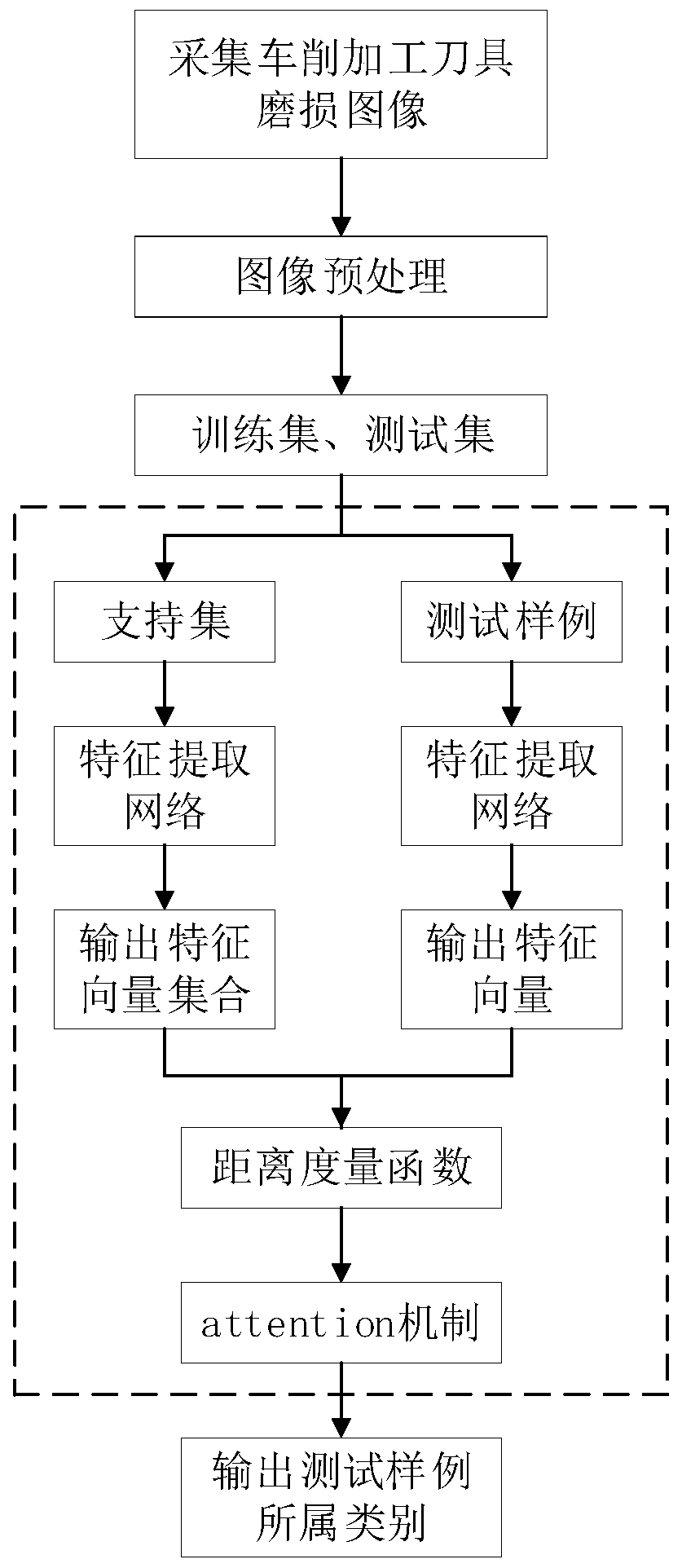

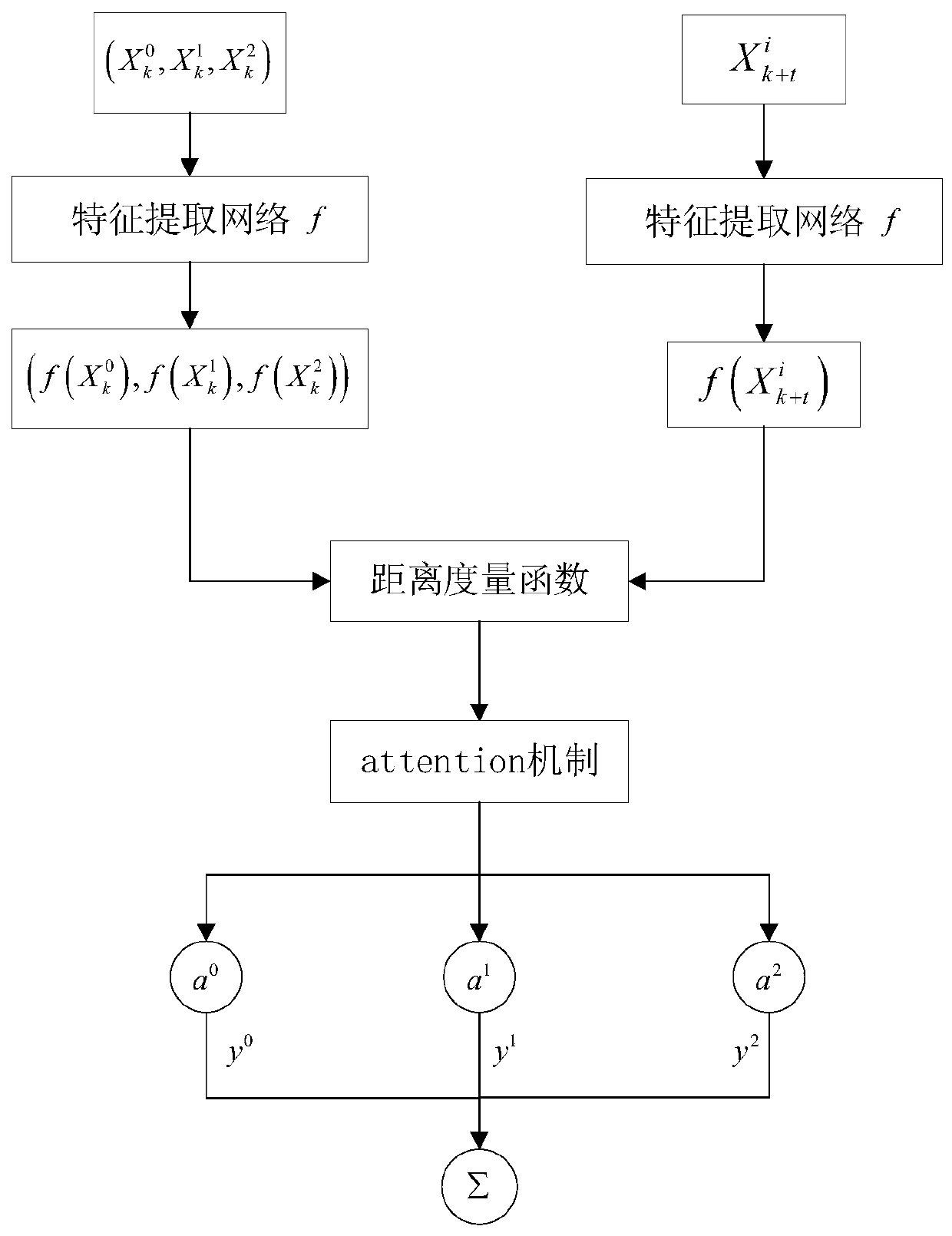

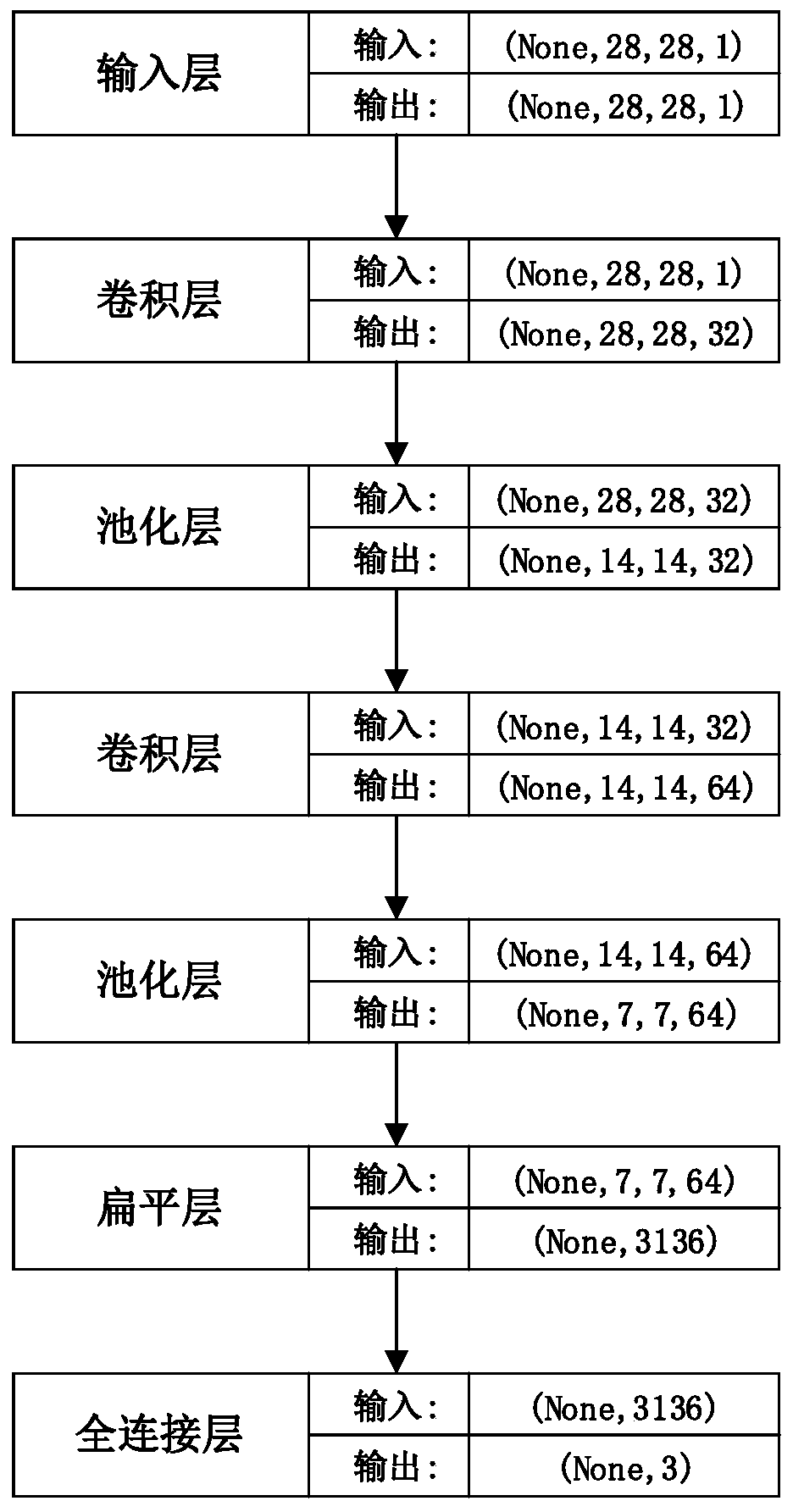

Turning tool wear state monitoring method based on metric learning

ActiveCN111242202AHigh recognition rate of wear stateImprove operational efficiencyCharacter and pattern recognitionNeural architecturesActivation functionAlgorithm

A turning tool wear state monitoring method based on metric learning comprises the steps: preprocessing a collected tool wear image and then randomly dividing the image into a training set and a testset in proportion, wherein the training set and the test set are each divided into a support set and a test sample set; establishing a non-parameterized neural network model structure, wherein the non-parameterized neural network model structure comprises a feature extraction network, a distance metric function and an action mechanism; initializing weight, deviation and learning rate parameters ofthe feature extraction network model, and constructing an activation function; taking a cosine distance function as a distance metric function, wherein the Attention mechanism uses a softmax layer structure, and the Attention mechanism uses a softmax layer structure; calculating the current cross entropy loss by using forward propagation, and calculating the gradient of the current cross entropyloss through backward propagation; optimizing the weight and the deviation by operating a gradient descent method; and finally predicting, classifying and distinguishing the test set by using the learning parameters of the network model, and outputting the prediction accuracy. The method has the characteristics of simple algorithm implementation, error correction, high tool wear state classification accuracy, short operation time, strong real-time performance and the like.

Owner:YANSHAN UNIV

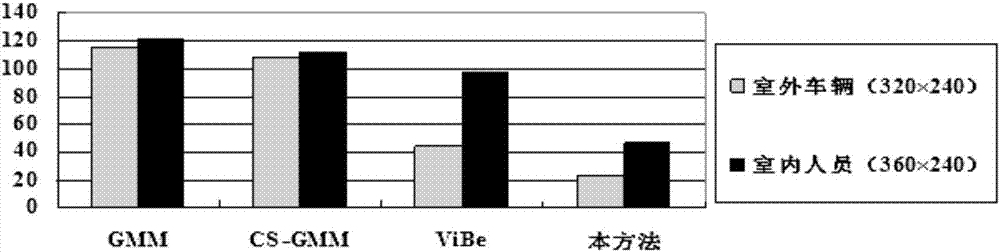

Real-time vision system oriented target compression sensing method

ActiveCN105095898AFast updateIncrease sampling rateCharacter and pattern recognitionComputer visionVisual perception

The invention discloses a real-time vision system oriented target compression sensing method, which comprises the following steps: image reconstruction, mixed compression sensing, high-efficient Vibe target detection, updating and post-processing, wherein the step of the image reconstruction comprises the following specific steps: according to the size of a collected image, carrying out 4*4 partitioning on an image, and converting obtained image blocks into 16*1 vectors; the step of the mixed compression sensing comprises the following specific steps: constructing the image block corresponding to a mixed sampling matrix, and carrying out sampling compression; the step of the high-efficient Vibe target detection comprises the following specific steps: for each pixel in the image block, comparing a pixel value with a sample set to judge whether the pixel belongs to a background point or not; the step of updating comprises the following specific steps: according to the above detection result, determining a background block area and a target block area in the image block, and obtaining the parameter regulation information of the mixed sampling matrix of a next frame of image of the pixel according to a situation that the pixel belongs to the background block area or the target block area; and the step of the post-processing comprises the following specific steps: carrying out image optimization processing on each image block of the current frame to obtain a final target image of the current frame.

Owner:SUZHOU INST OF TRADE & COMMERCE

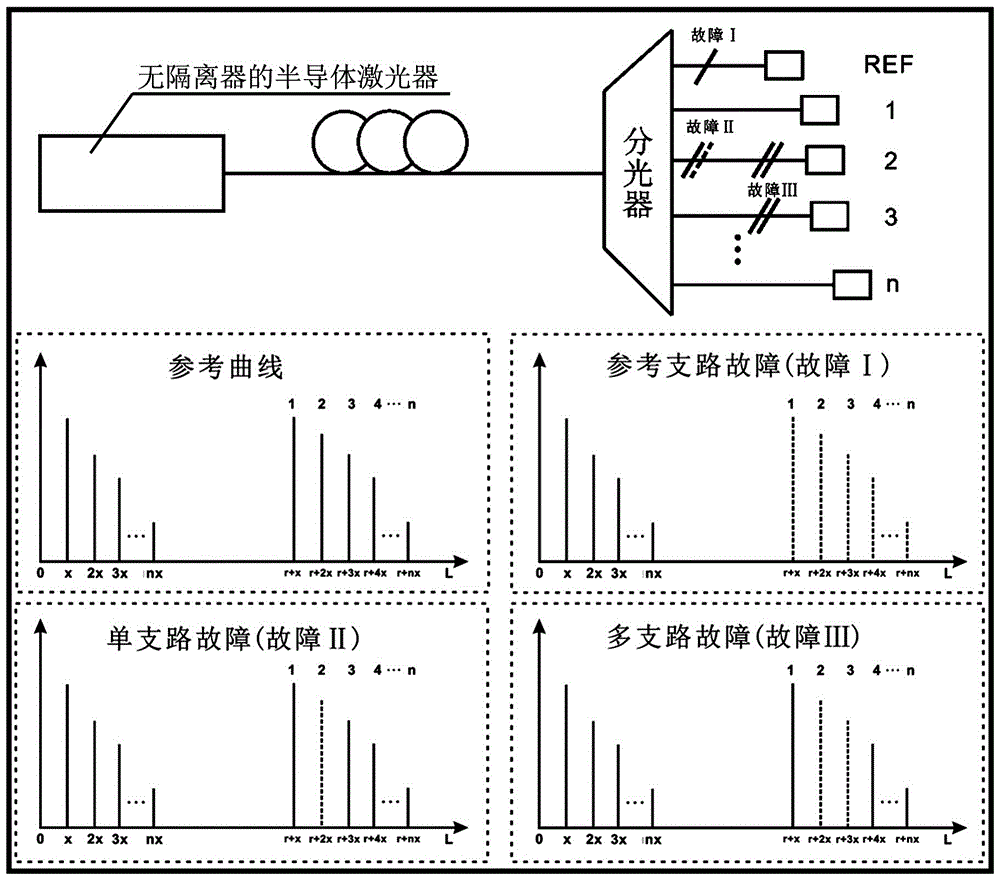

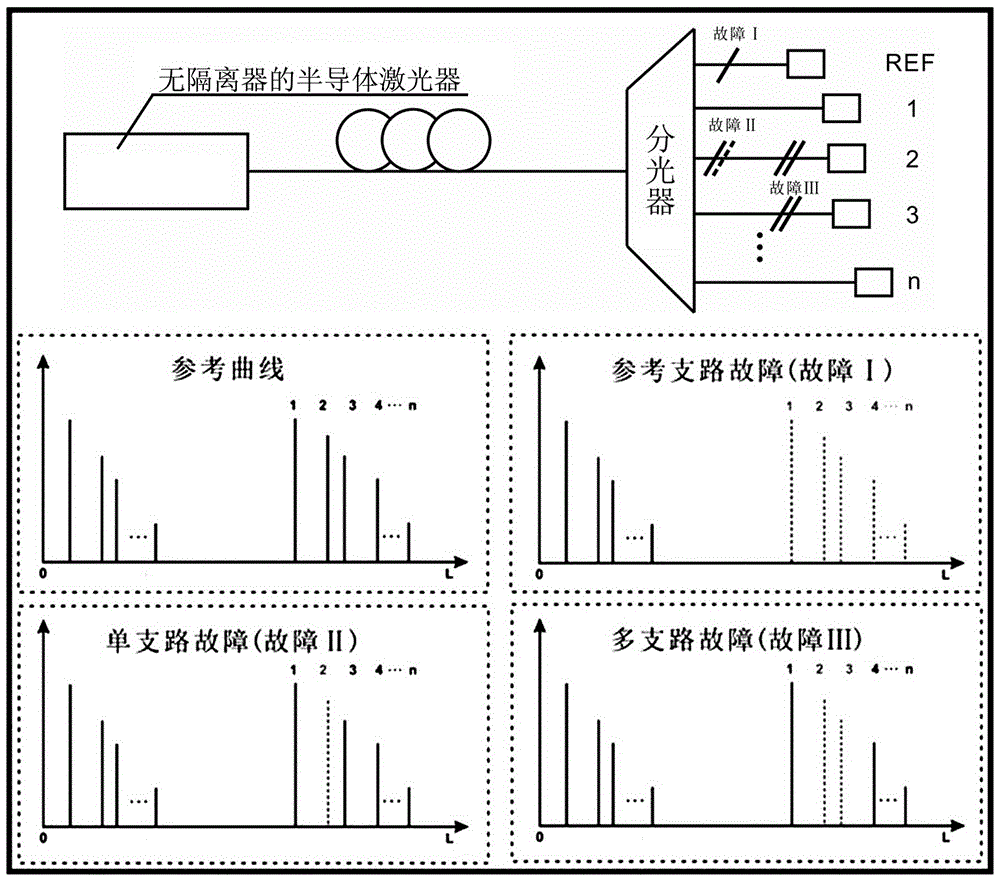

Device and method for rapidly detecting time division multiplexing optical network link fault

ActiveCN105959058AReduce the amount of calculation dataDetection speedElectromagnetic transmissionSoftware engineeringTime-division multiplexing

The invention relates to the optical fiber communication network fault detection technology, and particularly relates to a device and method for rapidly detecting a time division multiplexing optical network link fault. The problems of a large calculation data amount and a low detection speed of existing time division multiplexing passive optical network fault detection technology are solved. The device comprises a time division multiplexing optical network and a detection device. The time division multiplexing optical network comprises an optical transmitter and receiver, a feedback optical fiber, 1 to (n+1) path light splitter, (n+1) fibers, and n optical network units. The detection device comprises a semiconductor laser without an isolator, a coupler, an optical coupling device, a photoelectric detector, a signal acquisition and processing device, and (n+1) optical feedback devices. The device and the method are suitable for the time division multiplexing passive optical network fault detection.

Owner:TAIYUAN UNIV OF TECH

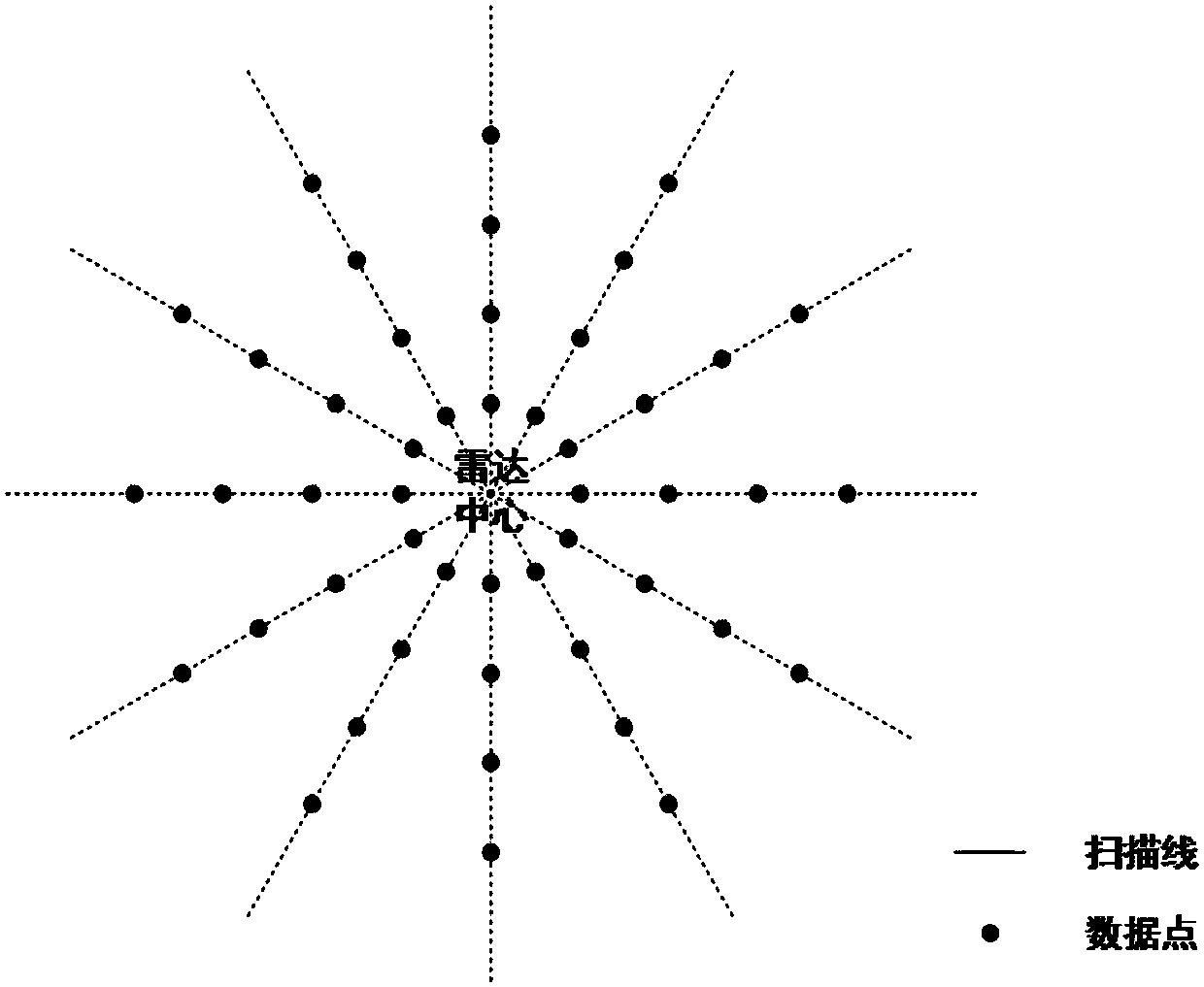

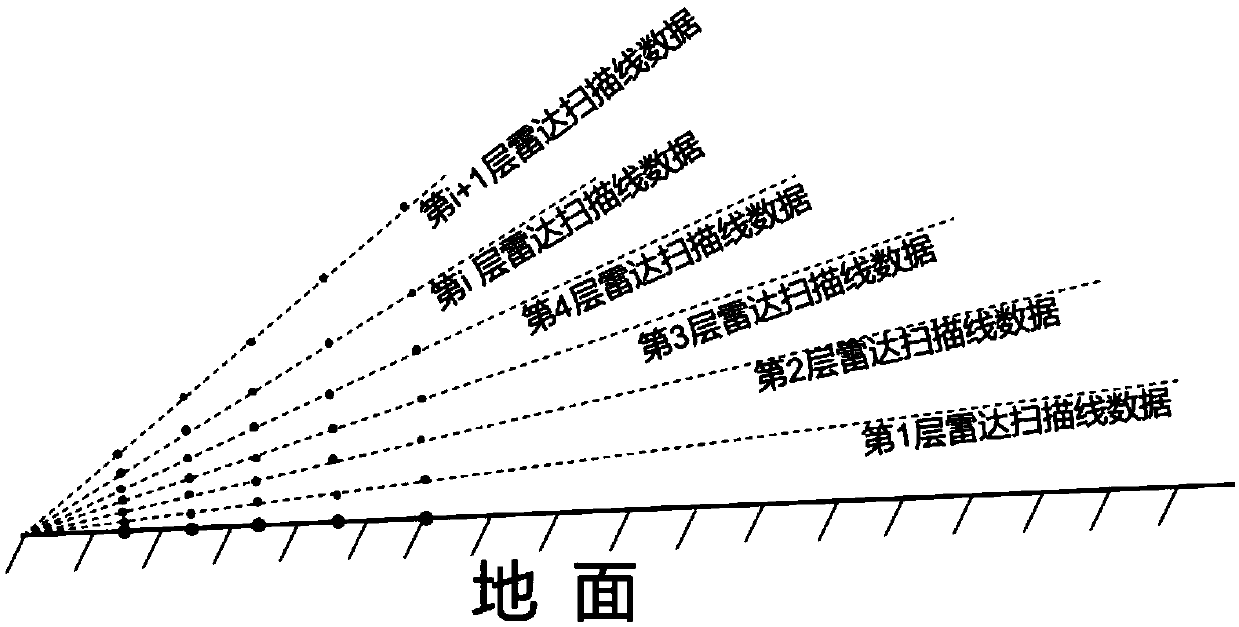

Method for quickly obtaining three-dimensional isosurface of radar reflectivity data

ActiveCN109031234AQuick fetchImprove acquisition efficiencyWave based measurement systemsEconomic benefitsRadar reflectivity

The invention provides a method for quickly obtaining a three-dimensional isosurface of a radar reflectivity data, which comprises following steps: normalizing a radar 3D scan data; constructing a hexahedral mesh of radar data points; and calculating the three-dimensional isosurface of the radar reflectivity data. According to the method for quickly obtaining a three-dimensional isosurface of a radar reflectivity data, the data of radar products can be well applied to 3D scenes by quickly obtaining three-dimensional isosurface of radar reflectivity data, which can provide effective decision-making for the reduction and prevention of meteorological disasters, and has good social and economic benefits; meanwhile, the response time of relevant departments to disasters can be shortened throughthe ability to quickly acquire the shape of rainfall clouds.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

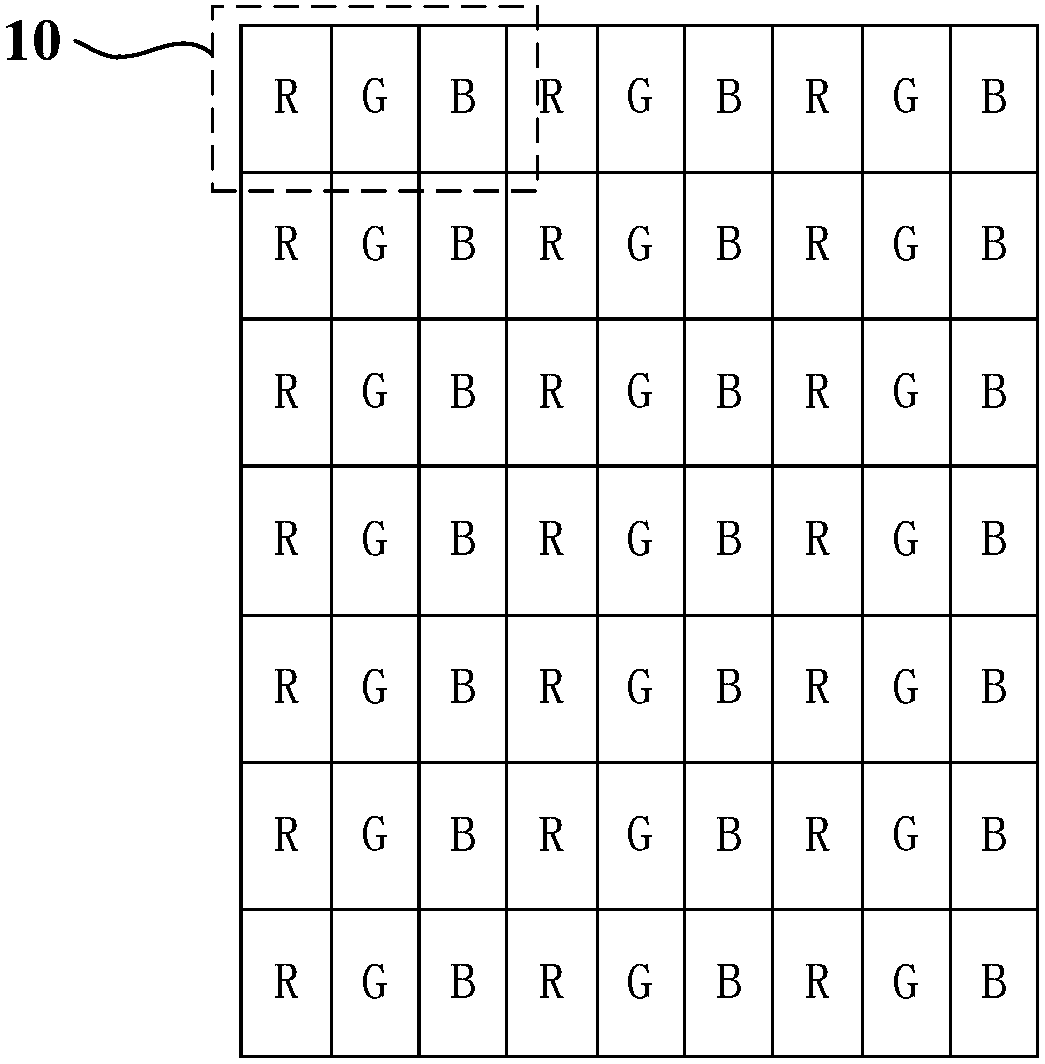

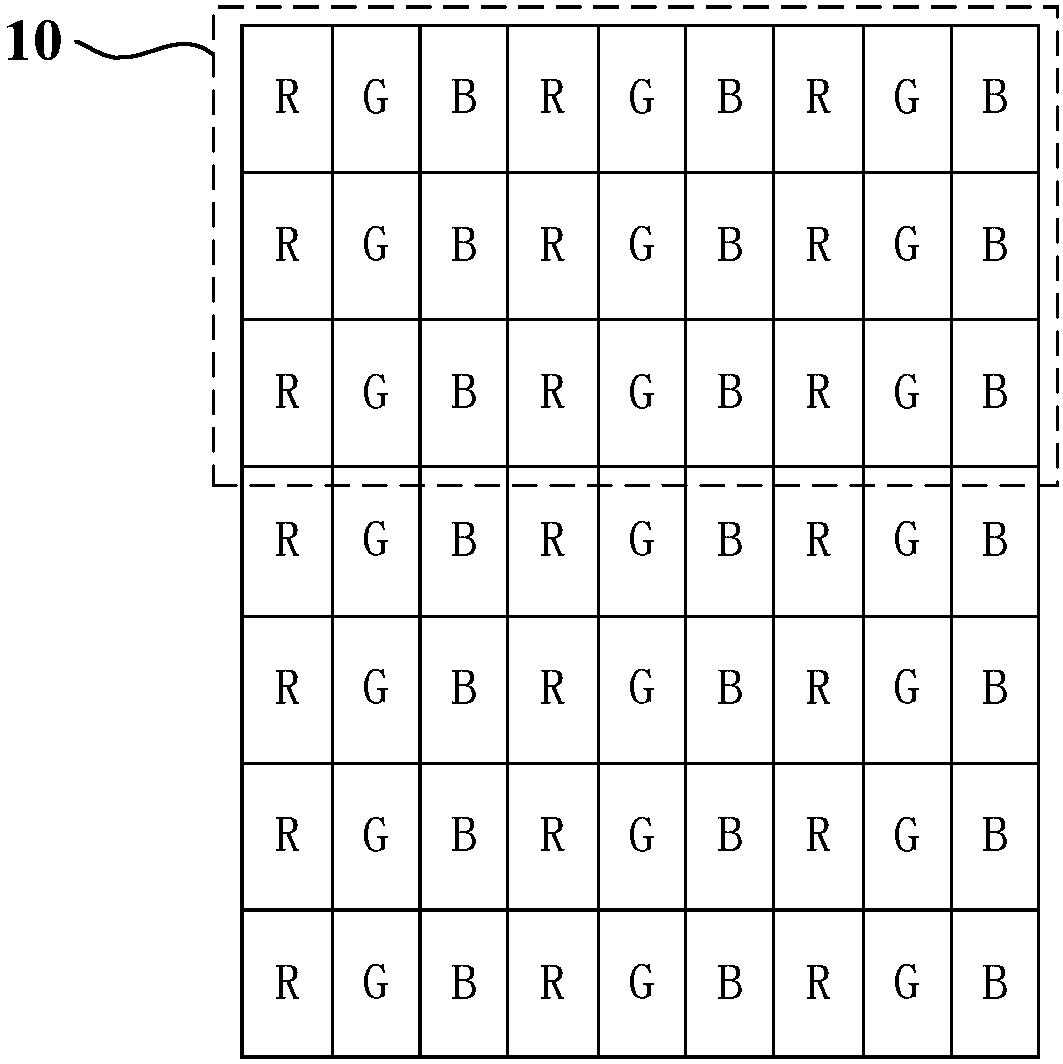

Grayscale compensation method, device and system for organic light-emitting display panel

PendingCN109559682AImprove computing efficiencyImprove brightness uniformityStatic indicating devicesLightnessGrayscale

The embodiment of the invention discloses a grayscale compensation method, device and system for an organic light-emitting display panel. The grayscale compensation method comprises the steps of determining a brightness-grayscale formula of each combined pixel unit according to the combined brightness of each combined pixel unit of the organic light-emitting display panel under at least three grayscales; and calculating a target grayscale value and a grayscale compensation value of each combined pixel unit according to the brightness-grayscale formula defined in the description and the targetcombined brightness of the combined pixel unit under the first grayscale. In the embodiment of the invention, grayscale compensation data calculation and grayscale compensation are carried out by taking the combined pixel unit as the minimum unit, the compensated picture is excellent in brightness uniformity, the number of taken pictures and the picture taking time are greatly reduced, the calculation process is simple, the calculated data is small in amount and facilitated to be stored, and the calculation efficiency of the grayscale compensation data is improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Cross-domain authentication and key agreement method based on block chain in Internet of Things environment

PendingCN114710275AAvoid failureSolve authentication problemsKey distribution for secure communicationPublic key for secure communicationEdge serverKey-agreement protocol

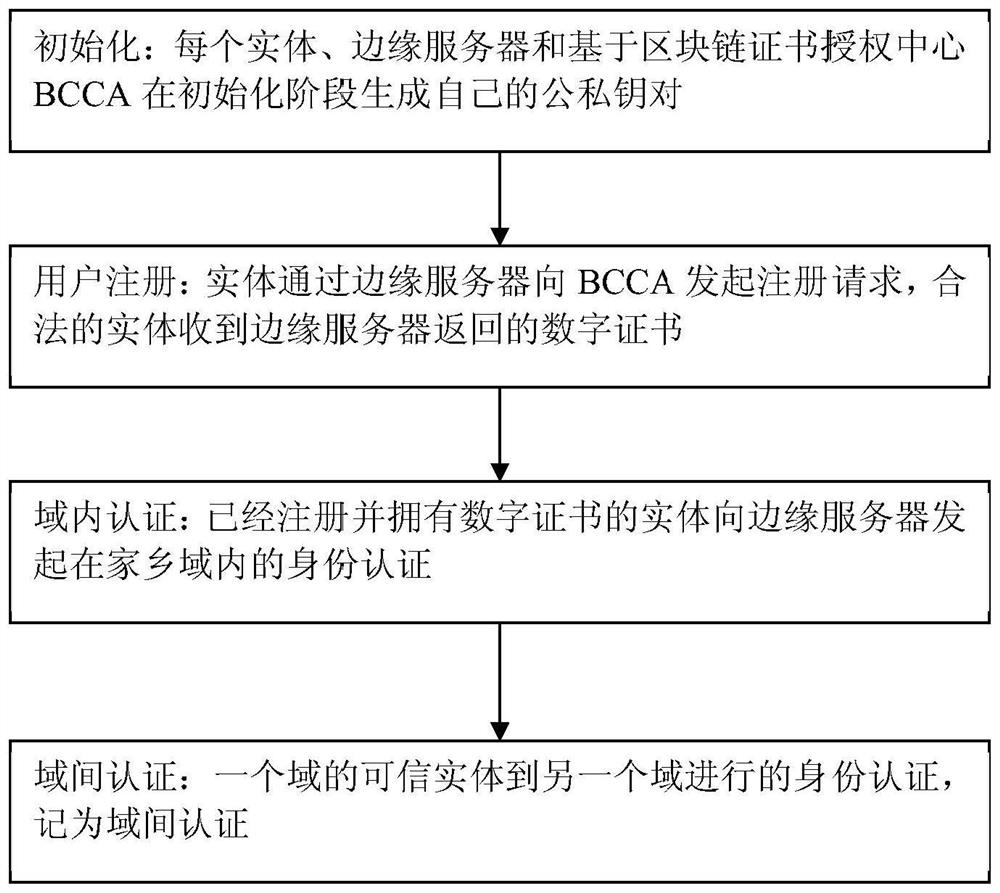

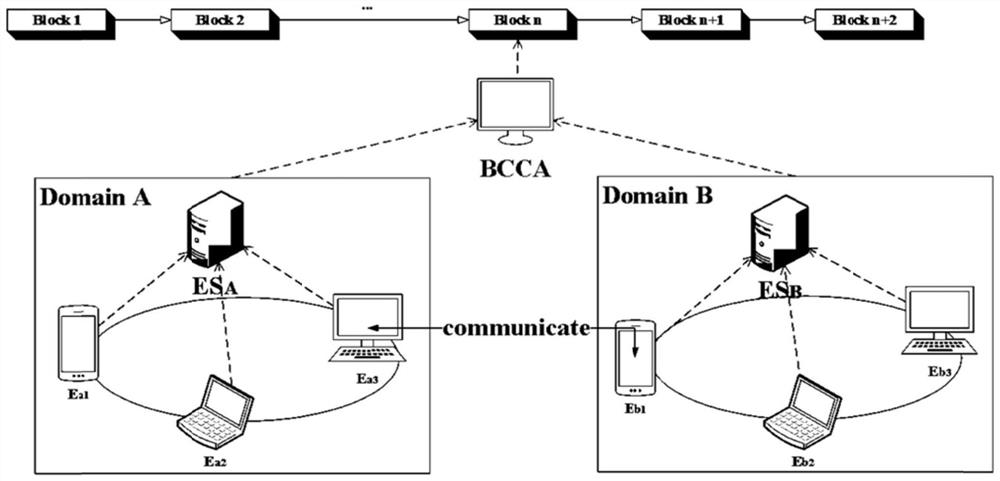

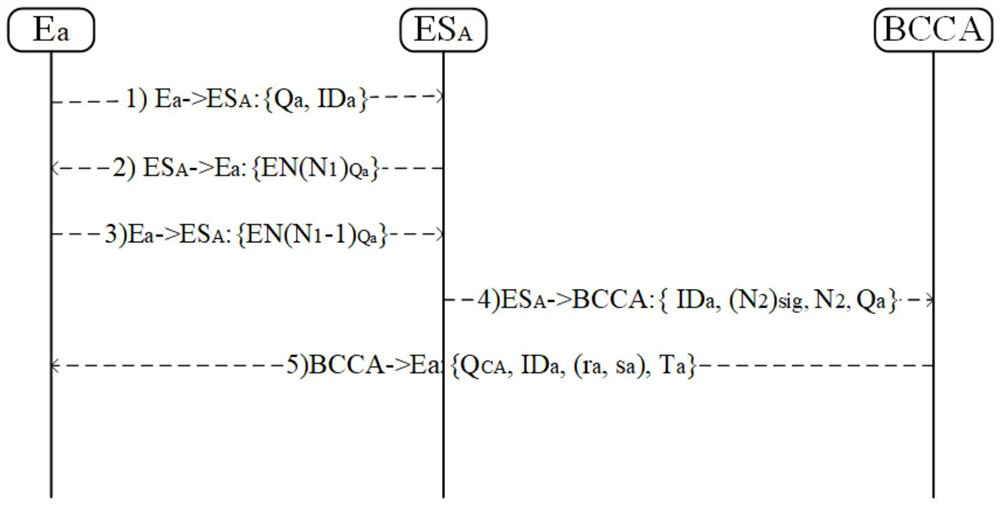

The invention discloses a cross-domain authentication and key negotiation method based on a block chain in an Internet of Things environment. The method comprises the following steps: (1) initialization: each entity, an edge server and a block chain-based certificate authority center BCCA generate own public and private key pairs in an initialization stage; (2) user registration: the entity initiates a registration request to the BCCA through the edge server, and the legal entity receives a digital certificate returned by the edge server; (3) intra-domain authentication: initiating identity authentication in the home domain to the edge server by the entity which has been registered and has the digital certificate; and (4) inter-domain authentication: identity authentication performed by the trusted entity of one domain to another domain is recorded as inter-domain authentication. According to the invention, an Internet of Things entity identity authentication and key agreement protocol based on an elliptic curve is designed, high-efficiency communication of low-performance terminal equipment is ensured, higher security performance can be provided, and the method is more suitable for Internet of Things edge equipment with lower performance.

Owner:HUNAN UNIV OF SCI & TECH

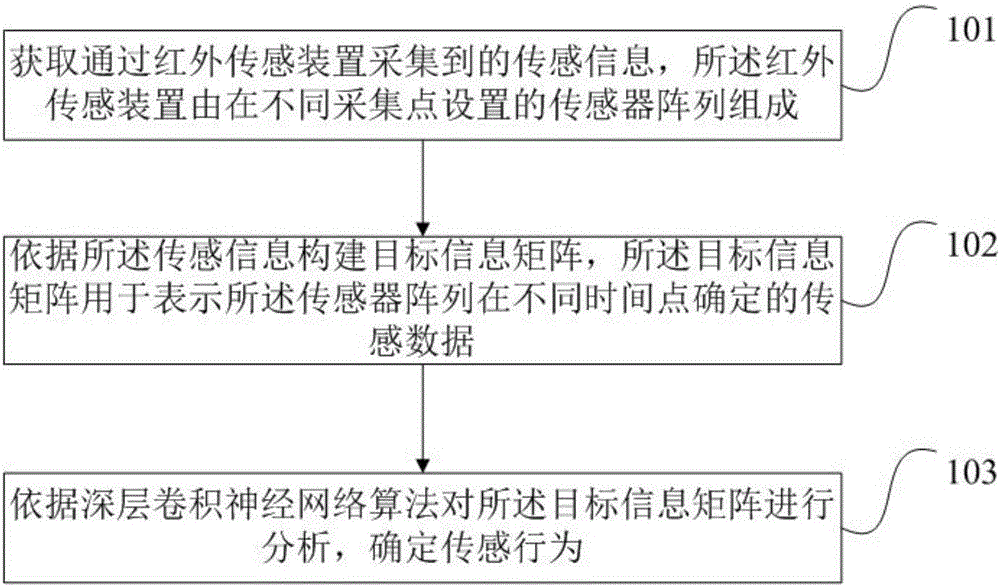

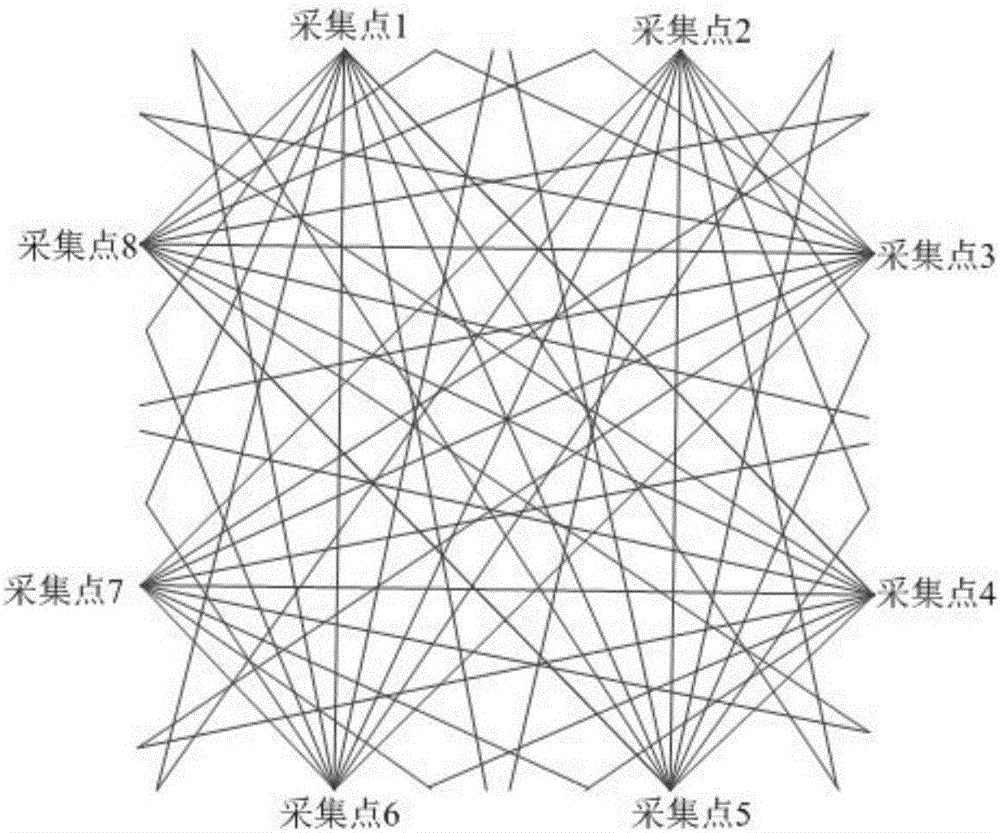

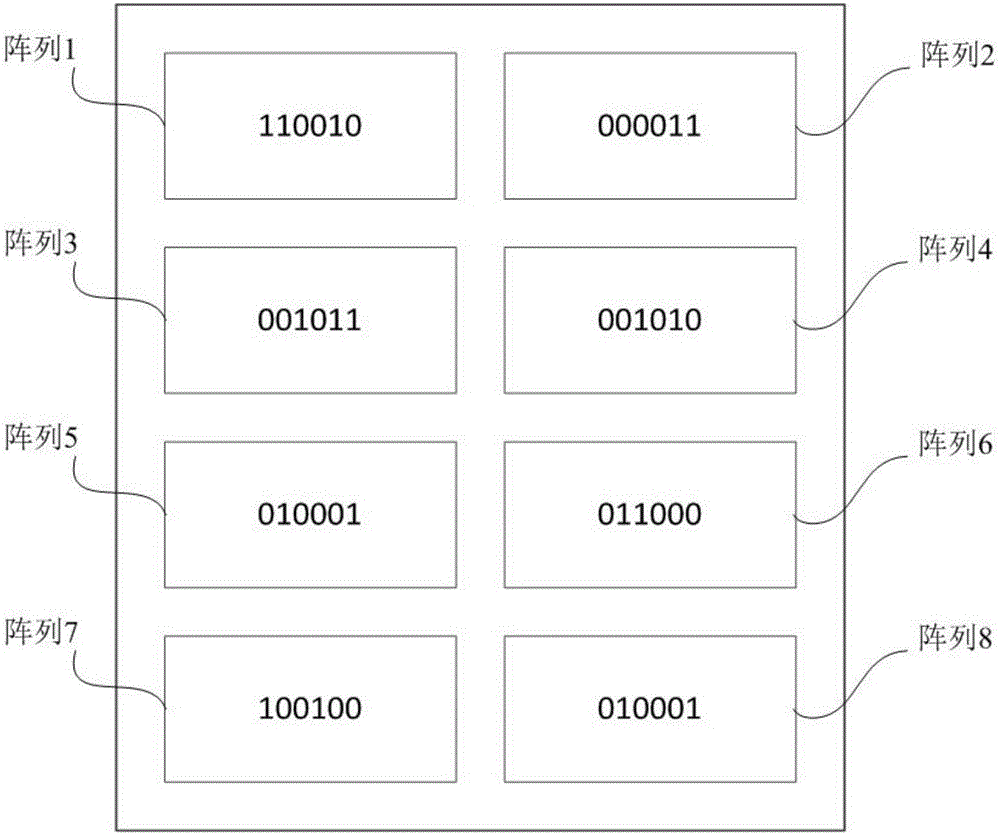

Sensing behavior recognition method and device

The invention discloses a sensing behavior recognition method and a sensing behavior recognition device. The sensing behavior recognition method comprises the following steps: acquiring sensing information acquired by an infrared sensing device, wherein the infrared sensing device consists of sensor arrays arranged at different acquisition points; according to the sensing information, establishing a target information matrix, wherein the target information matrix is used for showing sensing data determined by the sensor arrays at different time points; according to a deep convolution neural network algorithm, analyzing the target information matrix to determine a sensing behavior. Through the sensing behavior recognition method and the sensing behavior recognition device, small-calculation data amount, non-invasive, low-cost and small-volume body behavior recognition is achieved and the recognition accuracy rate is improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com