Calibration measurement method and system for single-frequency steady-state sine machinery vibrating amplitude phase characteristic

A technology for mechanical vibration and calibration measurement, which is applied to measurement devices, testing/calibration of velocity/acceleration/shock measurement equipment, and velocity/acceleration/shock measurement, etc. It can solve the problems of expensive calibration system, slow calculation speed, and limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0166] The present invention is further described below in conjunction with embodiment. The scope of the present invention is not limited by these examples, and the scope of the present invention is set forth in the claims.

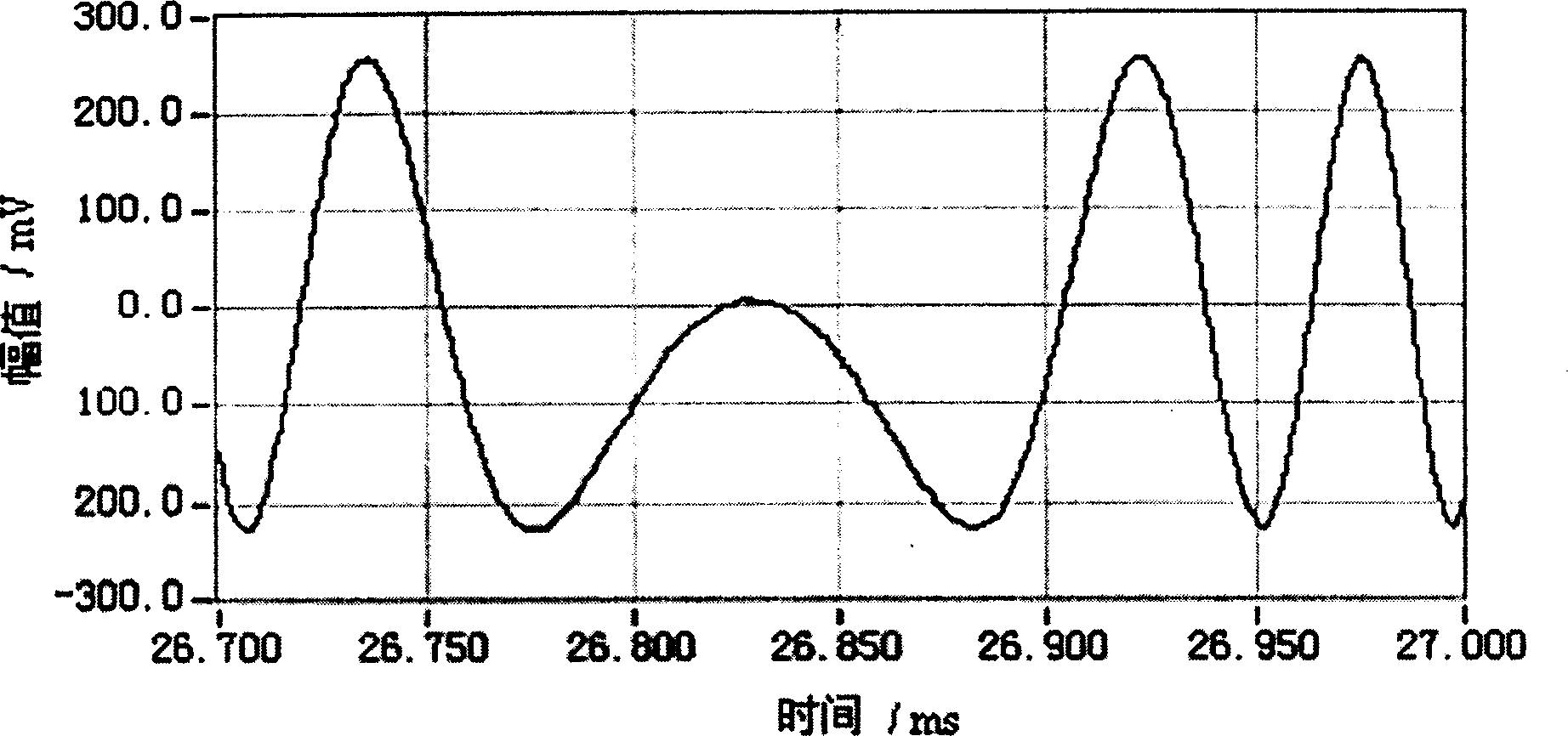

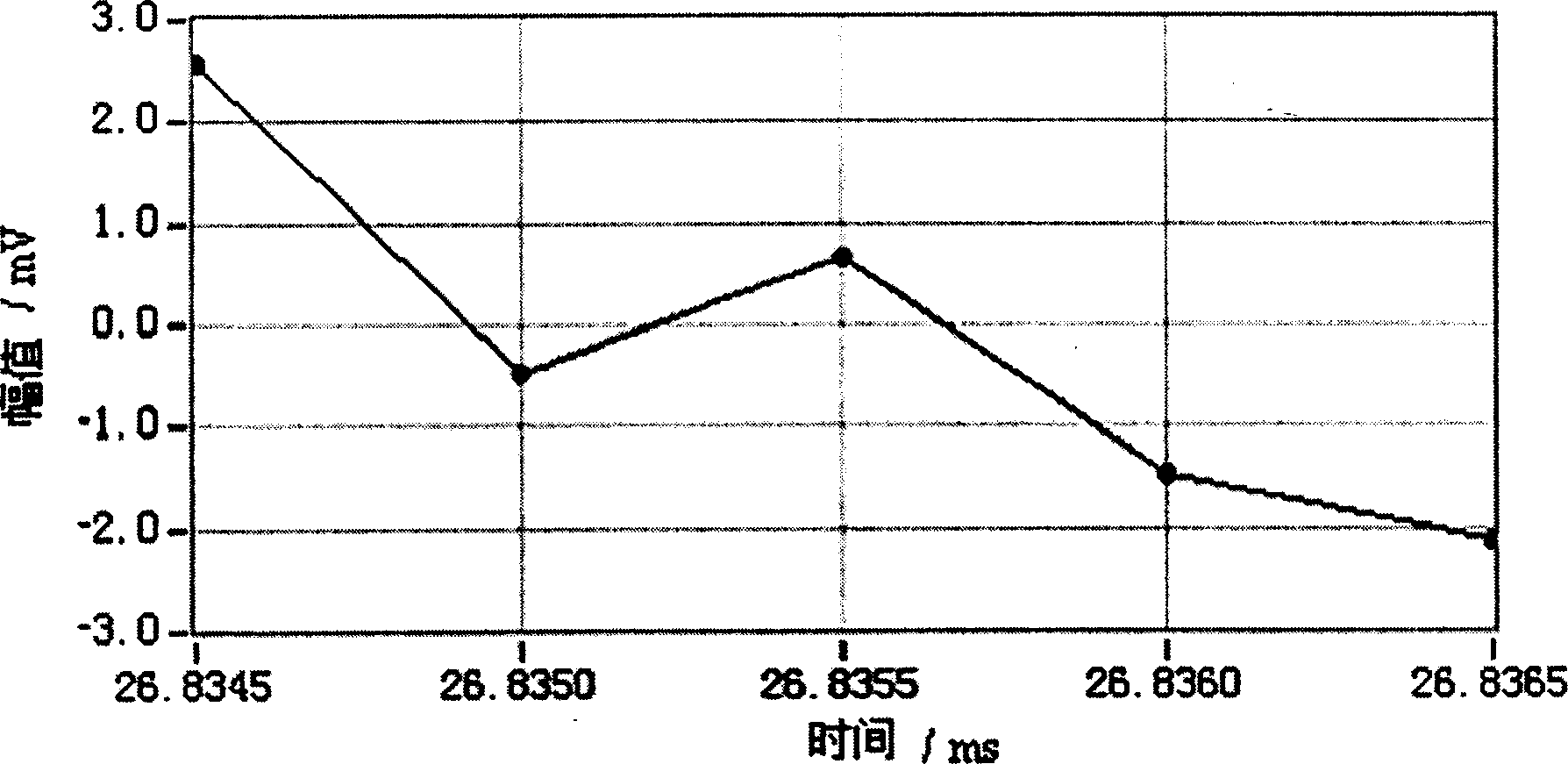

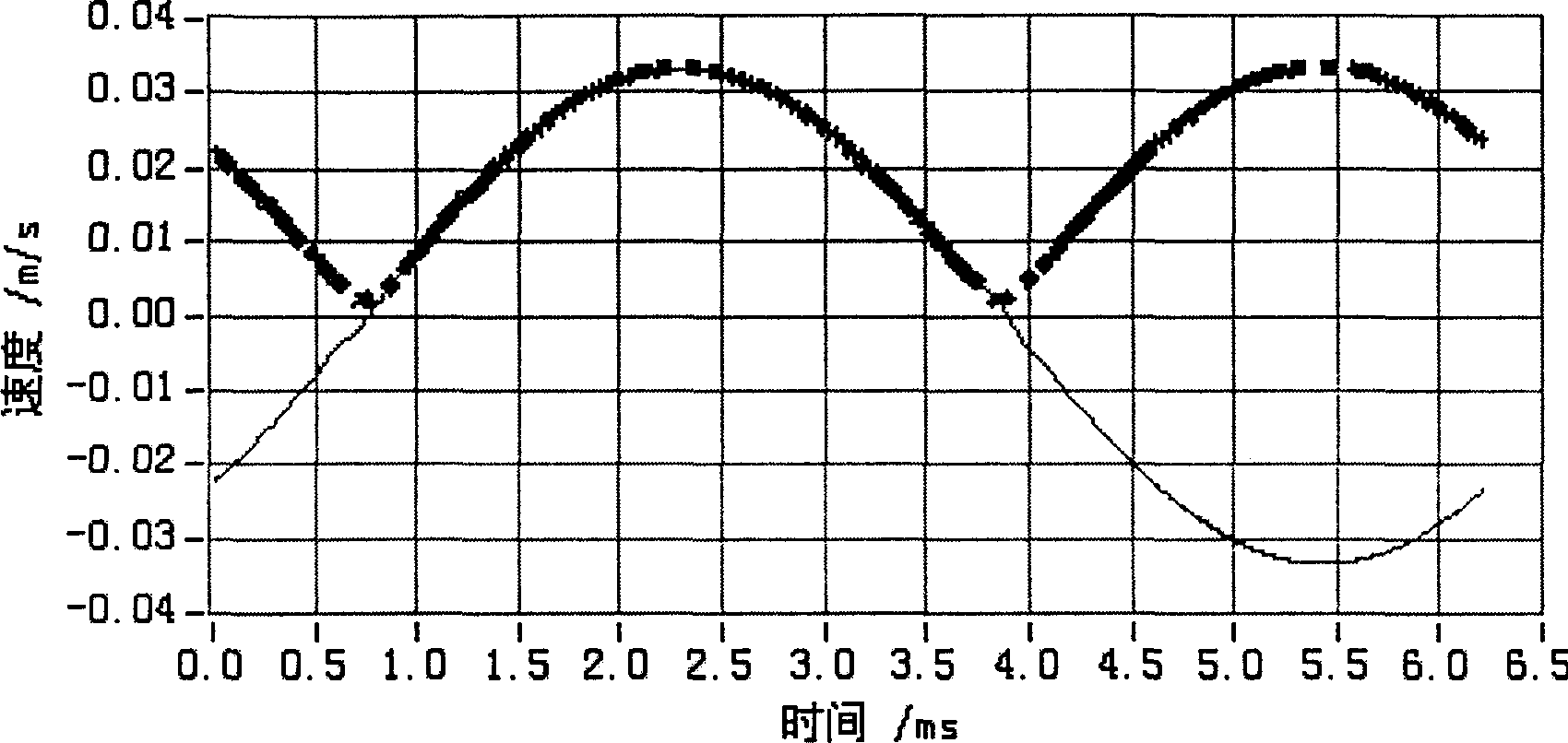

[0167] A calibration measurement method for the amplitude and phase characteristics of single-frequency steady-state sinusoidal mechanical vibration, the first reference vibration frequency point recommended by the international standard ISO 16063-11 is 160Hz and the calibration target acceleration is 100m / s 2 , Calibrate the acceleration sensor (including the supporting charge amplifier) of the model B&K8305. The measurement time is 100ms; the time interval is 500ns. The sampling rate of the data acquisition card is set to 2Msa / s; the coupling mode is DC coupling.

[0168] Calculate the sensitivity amplitude of the calibrated acceleration sensor according to the 16 steps 12.543mV / (m.s -2 ); the phase shift Δ is 0.25°.

[0169] The sensitivity am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com