TBM-carried rock slag online compressive strength testing system and method

A compressive strength and testing system technology, which is applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc. problem, to achieve the effect of strong timeliness and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

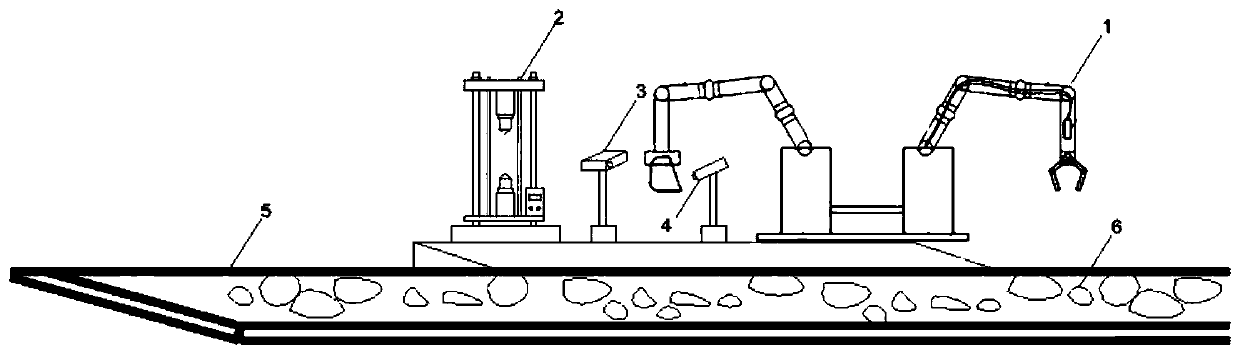

[0046] In one or more embodiments, a rock slag online compressive strength testing system carried by a TBM is disclosed, referring to figure 1 , including an industrial robot 1, a structured light projector 3, a CCD camera 4 and a compressive strength testing platform 2.

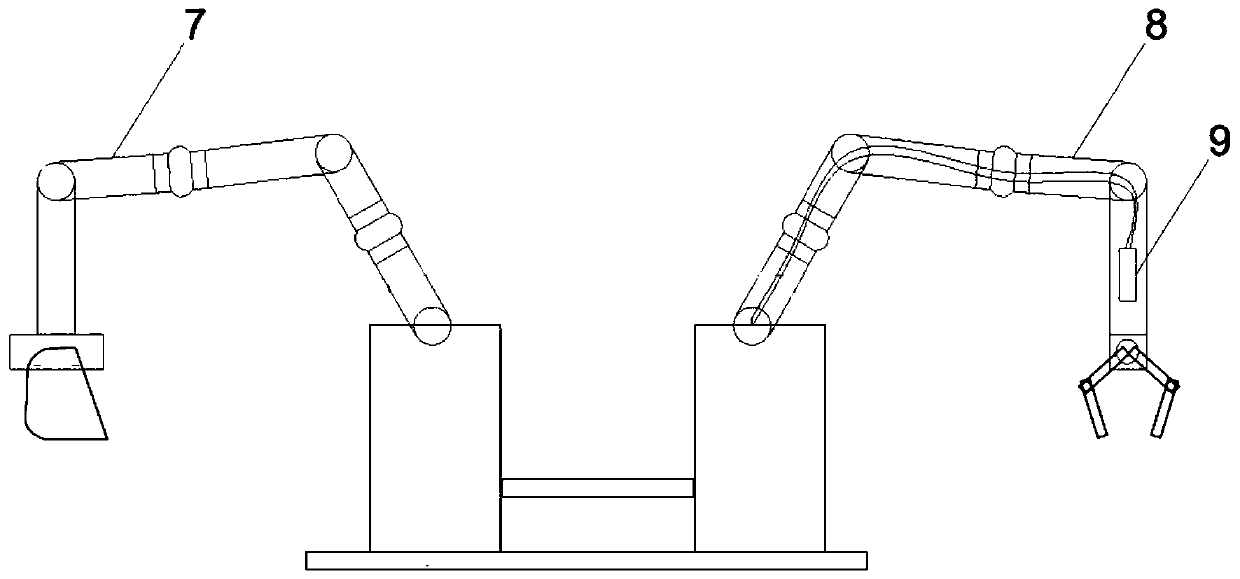

[0047] During the TBM construction process, the rock slag 6 produced by the excavation of the TBM cutter head is transported out of the tunnel by the belt conveyor. An industrial robot 1 is installed on one side of the belt conveyor conveying direction. The industrial robot 1 has a bucket mechanical arm 7 and a gripper mechanical arm 8 respectively. Rock slag obtained. Both the bucket mechanical arm 7 and the gripper mechanical arm 8 are six-degree-of-freedom mechanical arms, which make the operation of the mechanical arm more flexible for rock slag, and the rock slag can be adjusted to any position within the range of movement of the mechanical arm and any posture. Refer to the relative position relations...

Embodiment 2

[0078] In one or more embodiments, a method for testing the online compressive strength of rock slag carried by a TBM is disclosed, comprising the following steps:

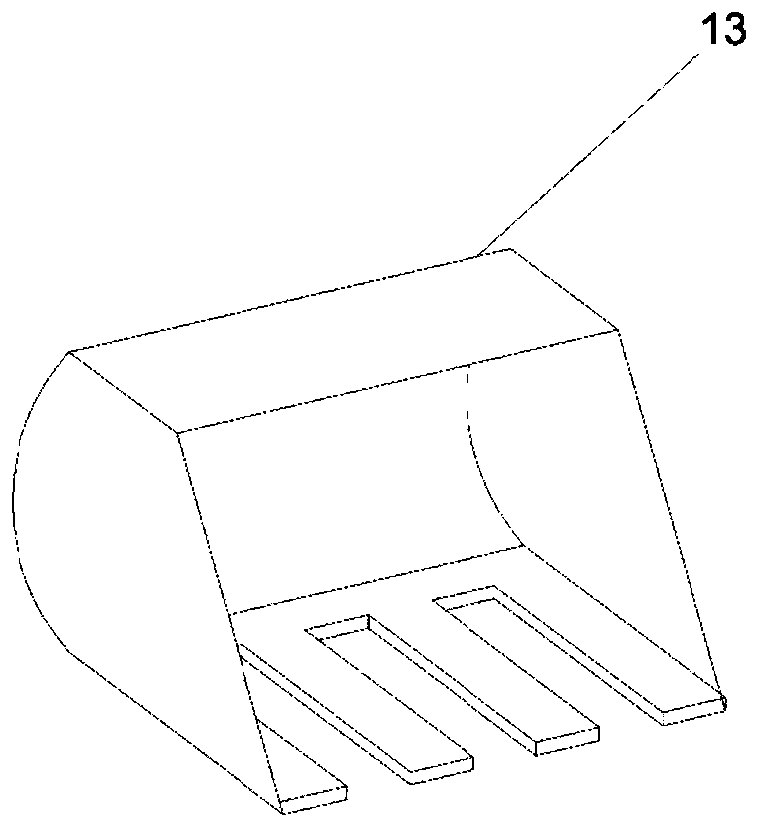

[0079] (1) The bucket mechanical arm 7 of the industrial robot 1 moves down close to the TBM belt conveyor and stays for one second to collect the rock slag on the belt conveyor. Since the distance between the two buckets 13 is 30mm, the particle size in the fast movement is less than 30mm Rock slag is screened out from the gap on the bottom surface of the bucket 13 and the gap between the two buckets 13.

[0080] (2) After the bucket mechanical arm 7 scoops up rock slag, the clamp arm moves immediately, and stretches in from the gap of the bucket 13 to clamp any rock slag in the bucket 13 .

[0081](3) After the tongs pick up the rock slag, the high-pressure nozzle 9 carried on the tongs mechanical arm 8 starts to clean off the dust on the rock slag.

[0082] (4) The gripper arm 8 hovers the rock residue at a de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com