Method for estimating compressive strength of concrete in early stage

A technology of compressive strength and concrete, which is applied in the direction of applying stable tension/compression to test the strength of materials, etc. It can solve the problems of how to know how the strength of concrete develops with age, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

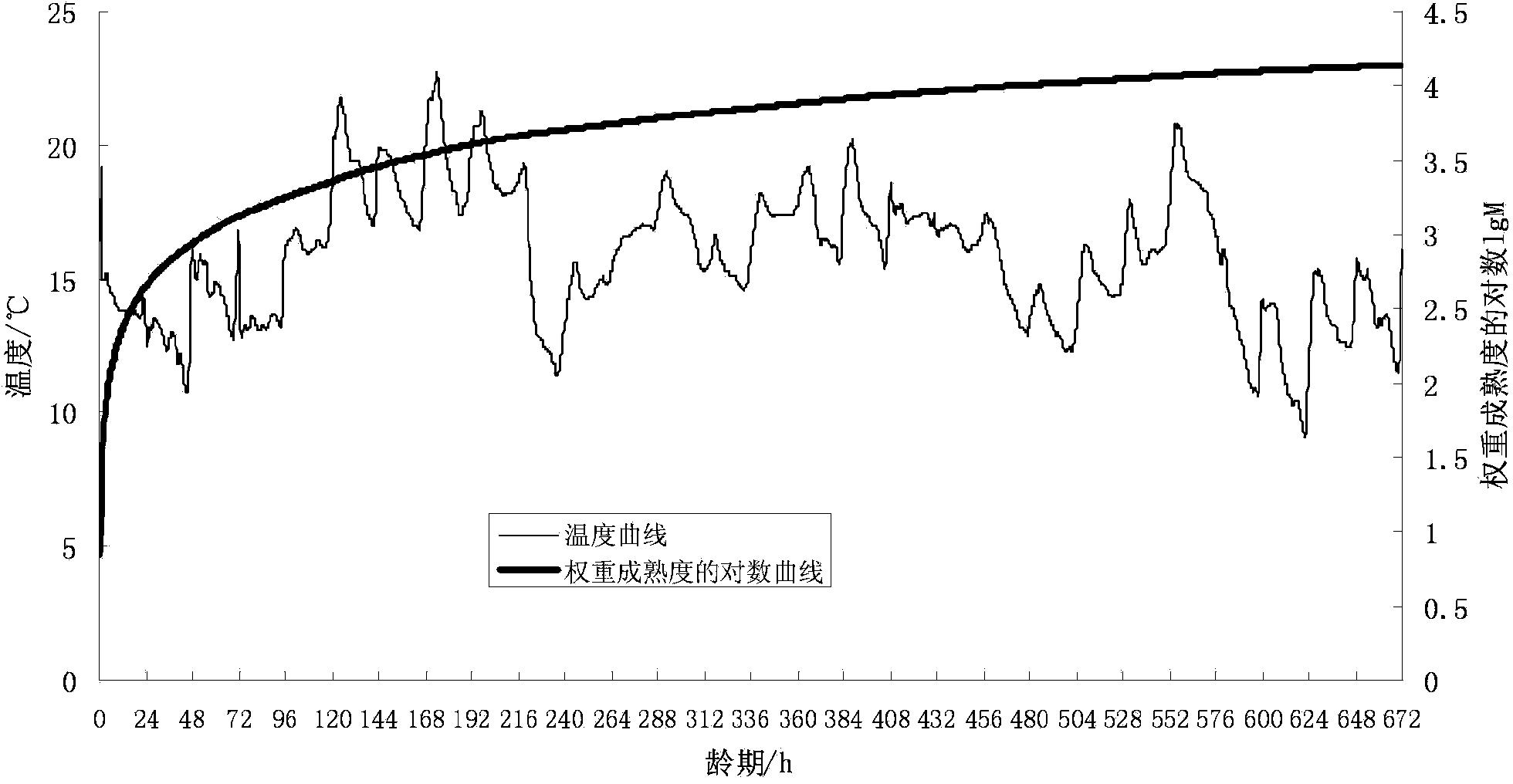

Examples

Embodiment 1

[0048] Embodiment 1: A certain 1# concrete mix ratio

[0049] Table 1, a 1# concrete mix ratio

[0050] water

cement

the sand

stone

Admixture

162

360

40

815

992

6.8

[0051] The mix ratio adopts a certain brand of P.Ⅱ42.5R cement, check the provisions of "General Portland Cement" GB175-2007, as shown in Table 2 below:

[0052] Table 2. Portland cement P.I content of general-purpose Portland cement

[0053]

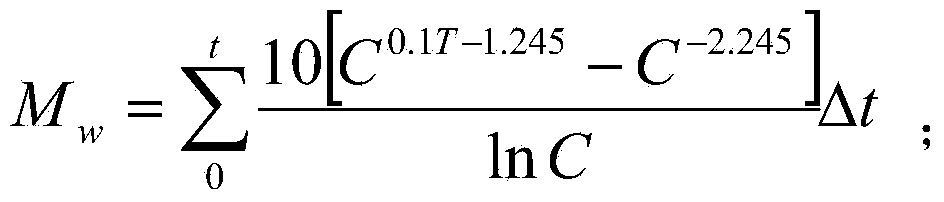

[0054] It can be seen from Table 2 that the Portland cement accounts for ≥95% of the total mass of the cement. According to the amount of cement and fly ash, the Portland cement accounts for ≥85.5% of the total mass of the cementitious material, and then according to the following table Take the value of C as shown in 3:

[0055] Table 3. C value in weight maturity method

[0056]

[0057]

[0058] As can be seen from Table 3, it is determined that the C value is 1.3 here.

[0059] When...

Embodiment 2

[0078] Embodiment 2: Certain 2# concrete mix ratio

[0079] Table 6, a 2# concrete mix ratio

[0080] water

cement

the sand

stone

Admixture

162

360

80

793

970

9.68

[0081] The mix ratio uses a certain brand of P.Ⅱ42.5R cement, check "General Portland Cement" GB175-2007, as shown in Table 2 in Example 1 above, it can be seen that the percentage of Portland cement in the total mass of cement is ≥95% , calculated according to the amount of cement and fly ash, Portland cement accounted for ≥ 77.7% of the total mass percentage of cementitious materials, and then according to the C value reference data, as shown in Table 3 in the above embodiment 1, determine the C value 1.3.

[0082] When placed in the humid heat curing box, the temperature is 20°C, and the results of calculating the weight maturity and strength are shown in Table 7 below:

[0083] Table 7. Test results of a 2# concrete mix ratio weight m...

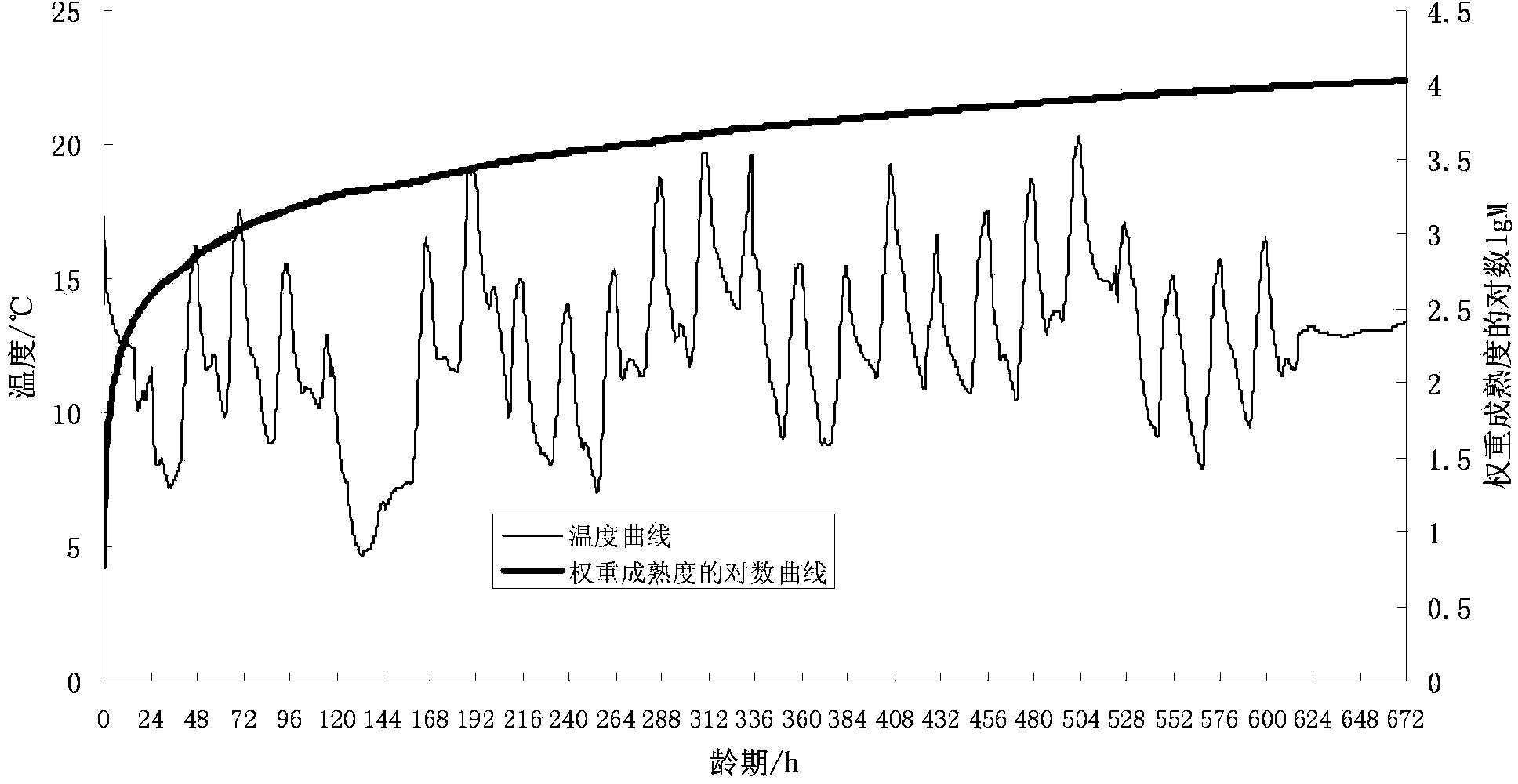

Embodiment 3

[0089] Embodiment 3: certain 3# concrete mix ratio

[0090] Table 8, a 2# concrete mix ratio

[0091]

[0092]

[0093] The mix ratio uses a certain brand of P.Ⅱ42.5R cement. Check its factory report, it can be seen that the Portland cement accounts for 95% of the total mass of cement. It is calculated according to the amount of cement, fly ash and slag powder. The cement accounts for 61.9% of the total mass of the cementitious material, and then according to the C value reference data (when the C value is greater than 65%, the C value is 1.3, when the C value is 50% to 64%, the C value is 1.4, and when the C value is 35% to 49%, the C value is 1.5, When 35% to 49%, the C value is 1.5), and the C value is determined to be 1.4.

[0094] When placed in the humid heat curing box, the temperature is 20°C, and the results of calculating the weight maturity and strength are as follows:

[0095] Age 24h:

[0096] Among them, 1.5h is from 20°C to 55°C, this part is calculated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com