High-performance powder concrete for 3D (three-dimensional) printing

A technology of powder concrete and 3D printing, which is applied in the field of concrete, can solve problems such as difficulty in forming high-strength concrete structures, unfavorable structural stability of buildings, and lack of fast-setting performance, so as to save building materials and energy consumption, and has good durability. The effect of short construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

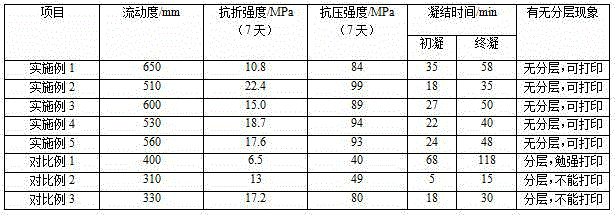

Examples

Embodiment 1

[0055] A high-performance powder concrete for 3D printing is made from raw materials with the following weight components:

[0056] 500 parts of ordinary Portland cement with an average particle size of 20-60 μm and no less than grade 42.5;

[0057] 250 parts of active mineral admixture with an average particle size of 0.1-60 μm and an activity index greater than 120% within 7 days;

[0058] 800 parts of inert fillers with a particle size of less than 2.5mm;

[0059] 10 parts of composite high-efficiency superplasticizer powder with water reducing rate greater than 30%;

[0060] 2 parts of thickener;

[0061] 4 parts of self-curing agent;

[0062] 2 parts of non-alkali fast setting time regulator;

[0063] 145 parts of water;

[0064] 3 parts of organic fiber with a length of 6~12mm;

[0065] 40 pieces of copper-plated fiber with a length of 6~15mm and a diameter of 0.08~0.25mm.

[0066] Wherein, the alkali-free rapid time regulator is prepared by mixing the following r...

Embodiment 2

[0074] Except that the high-performance powder concrete used for 3D printing, alkali-free fast setting time regulator, active mineral admixture, and self-curing agent have different formulations, the others are the same as in Example 1;

[0075] A high-performance powder concrete for 3D printing is made from raw materials with the following weight components:

[0076] 900 parts of ordinary Portland cement with an average particle size of 20-60 μm and no less than grade 42.5;

[0077] 350 parts of active mineral admixture with an average particle size of 0.1-60 μm and an activity index greater than 120% within 7 days;

[0078] 1300 parts of inert fillers with a particle size of less than 2.5mm;

[0079] 20 parts of compound high-efficiency superplasticizer powder with water reducing rate greater than 30%;

[0080] 5 parts of thickener;

[0081] 10 parts of self-curing agent;

[0082] 10 parts of alkali-free fast setting time regulator;

[0083] 230 parts of water;

[0084...

Embodiment 3

[0089] Except that the formula of the high-performance powder concrete used for 3D printing is different, other is the same as embodiment 1;

[0090] A high-performance powder concrete for 3D printing is made from raw materials with the following weight components:

[0091] 700 parts of ordinary Portland cement with an average particle size of 20-60 μm and no less than grade 42.5;

[0092] 270 parts of active mineral admixture with an average particle size of 0.1-60 μm and an activity index greater than 120% within 7 days;

[0093] 900 parts of inert fillers with a particle size of less than 2.5mm;

[0094] 15 parts of composite high-efficiency superplasticizer powder with water reducing rate greater than 30%;

[0095] 3 parts of thickener;

[0096] 6 parts of self-curing agent;

[0097] 5 parts of non-alkali fast setting time regulator;

[0098] 180 parts of water;

[0099] 3 parts of organic fiber with a length of 6~12mm;

[0100] 100 pieces of copper-plated fiber wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com