Blasting damaged rock sample preparation and micro-macro combined damage degree determination method

A technology of damage degree and measurement method, which is applied in the field of blasting damaged rock sample preparation and damage degree measurement combined with macro and mesoscopic, can solve the problems of rock dynamic damage, inability to accurately quantify blasting, etc., and achieve simple operation and comprehensive and reliable test data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

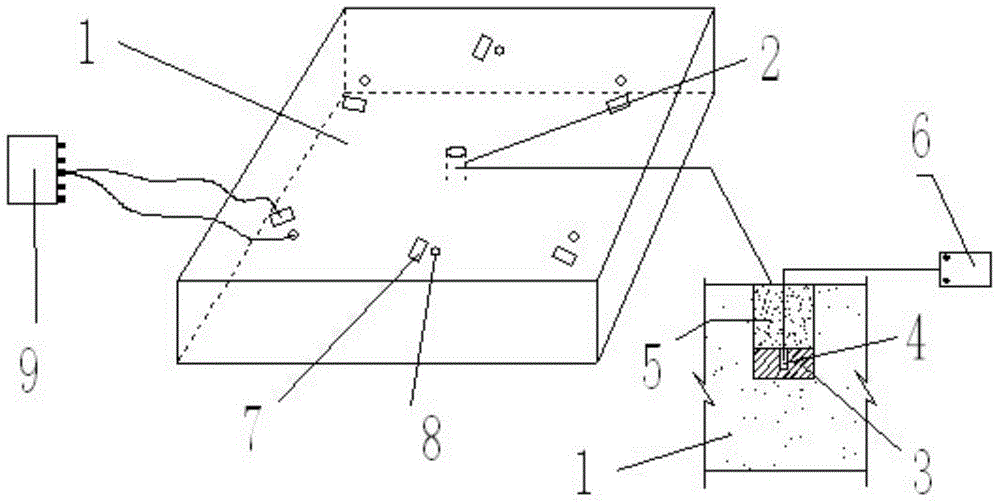

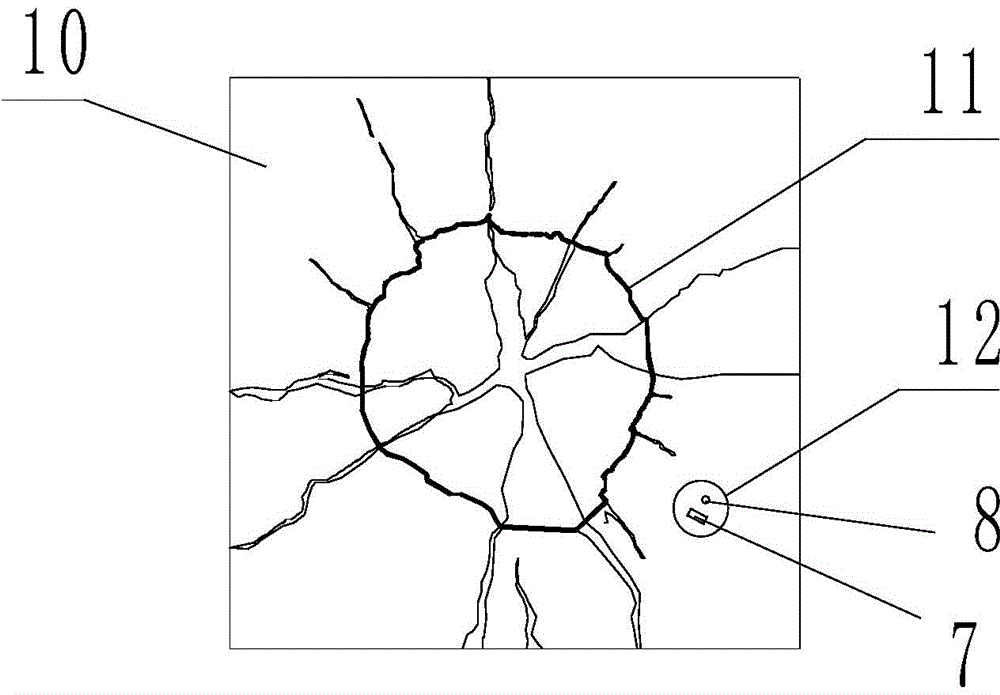

[0032] Embodiment 1: the method for determining the degree of damage includes: preparation of blasting damaged rock samples, mesoscopic test for blasting damaged rock samples and macroscopic test for blasting damaged rock samples;

[0033] 1. The preparation of blasting damaged rock samples includes the following steps:

[0034] a. Make a rock specimen of length × width × thickness = 500mm × 500mm × 105mm, wherein the length and width are not limited to 500mm, which is equivalent to this, and a blast hole is drilled along the thickness direction at the center of the upper surface, and the aperture is ≤ 10mm. Hole depth 53mm;

[0035] b. Paste resistance strain gauges and acceleration sensors at key points on the upper surface, and connect them to the ultra-dynamic signal test analyzer through data lines;

[0036] c. Place quantitative explosives and detonators in the central borehole, seal the hole with gun mud, and use the detonator to blast;

[0037] d. Use the ultra-dynam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com