Full-automatic intelligent concrete curing detection system and method

A detection system and concrete technology, which is applied in the direction of measuring devices, preparation of test samples, and application of stable tension/pressure to test the strength of materials, etc., can solve problems such as labor-intensive, low efficiency, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

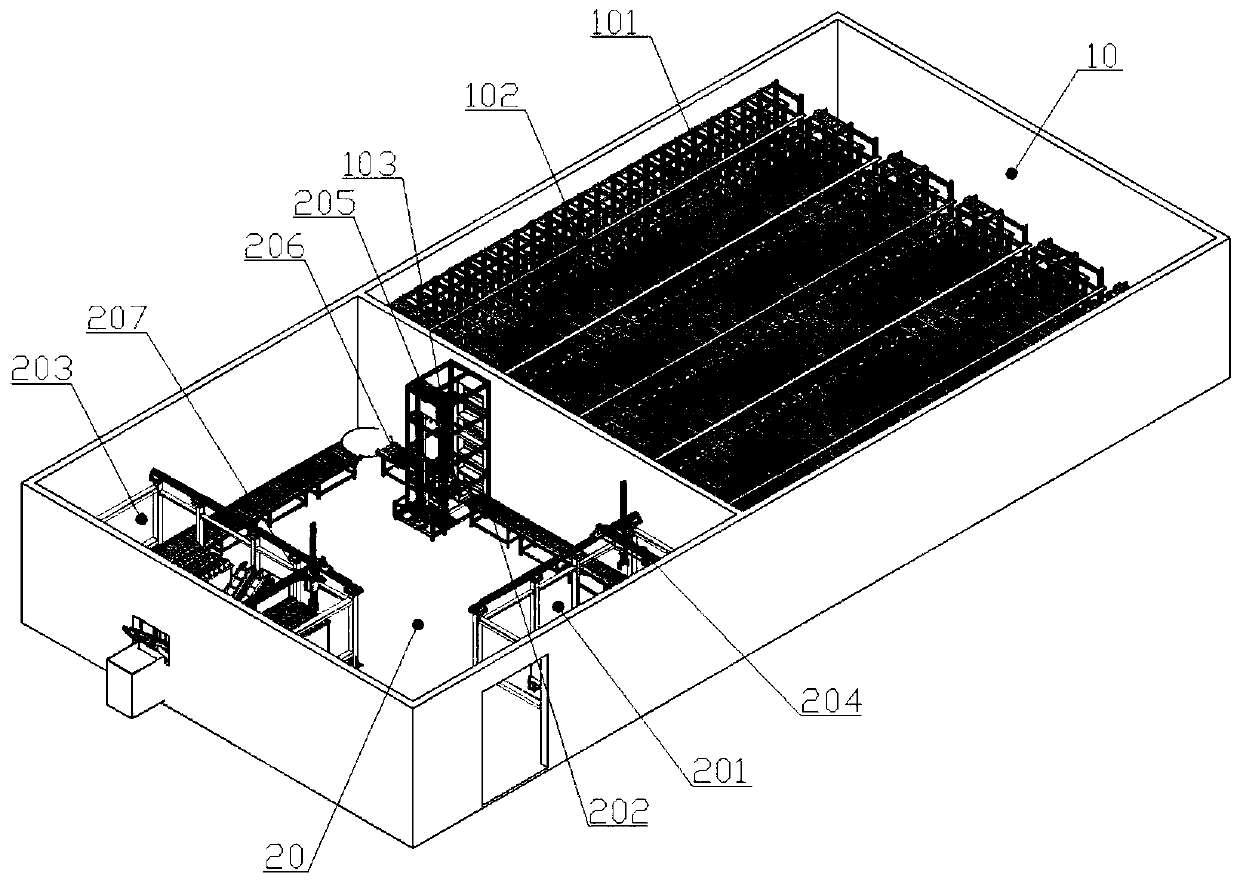

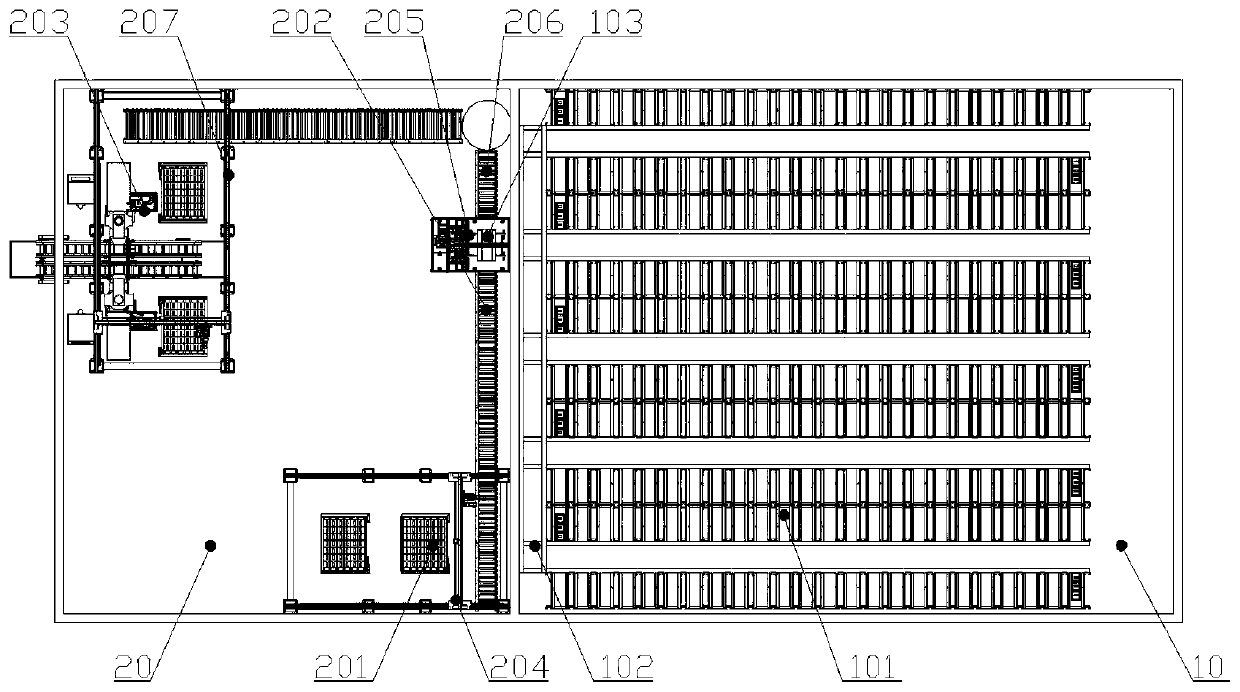

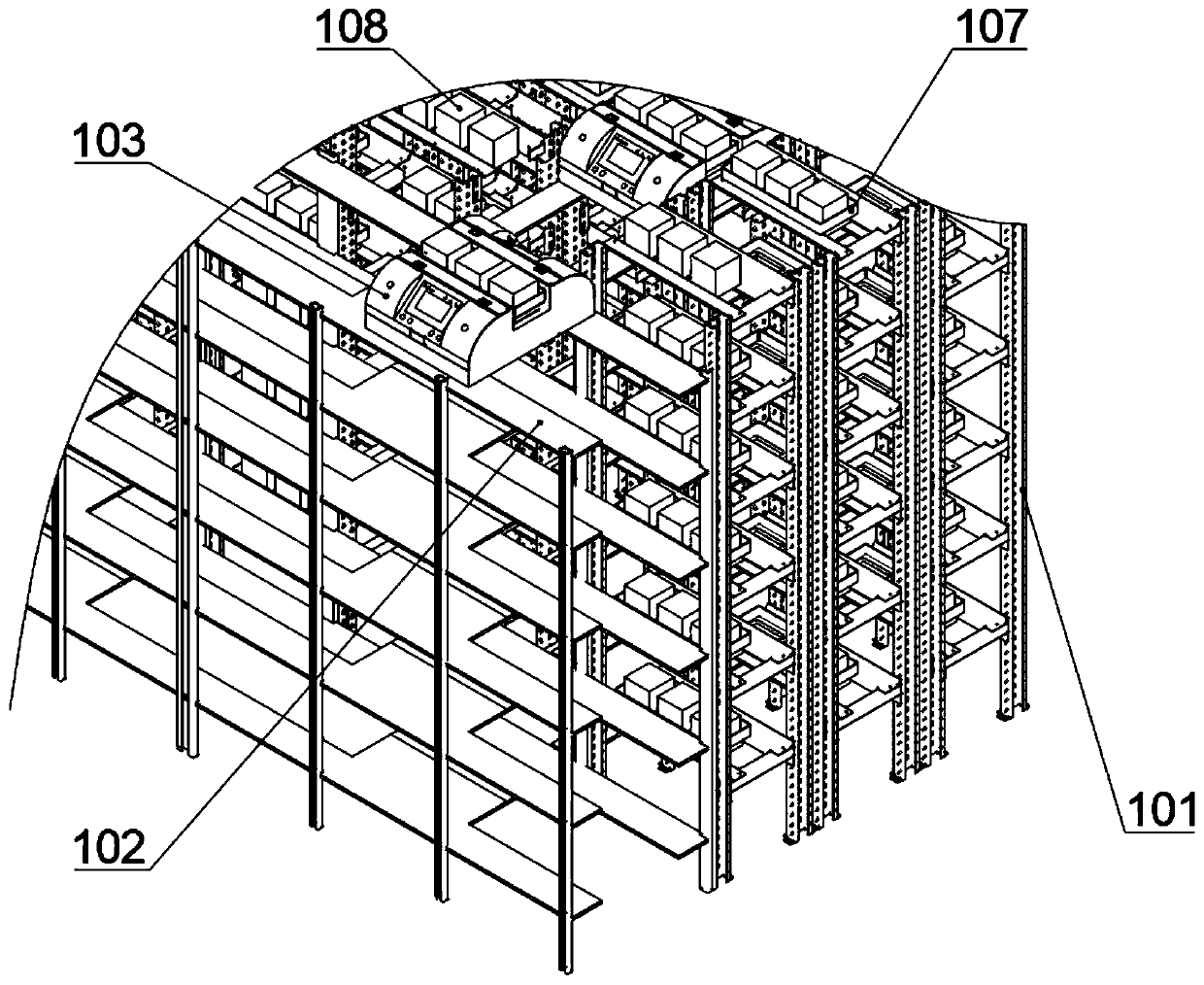

[0037] see figure 1 and figure 2 As shown, the full-automatic intelligent concrete curing detection system of the present invention can be divided into two areas, one of which is a standard curing room 10 with constant temperature and humidity (the temperature is 20 ± 2° C., and the relative humidity is more than 95%), and the second Concrete specimen turnover and testing area 20, turnover and testing area 20 includes warehousing and loading area 201 for specimens to be cured, warehousing delivery device 202, and compressive strength testing area 203, each component in the two areas The control system coordinates the work to realize fully automatic intelligent concrete maintenance and detection.

[0038] The specimen to be cured is manually entered into the dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com