Concrete early strength agent and preparation method thereof

An early-strength agent and concrete technology, applied in the field of concrete early-strength agent and its preparation, can solve the problems of insufficient C-S-H gel amount, decrease in system strength, unhelpful stone body strength, etc., and achieve the improvement of overall structural strength and the enhancement of early-stage frost resistance. , the effect of shortening the hardening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

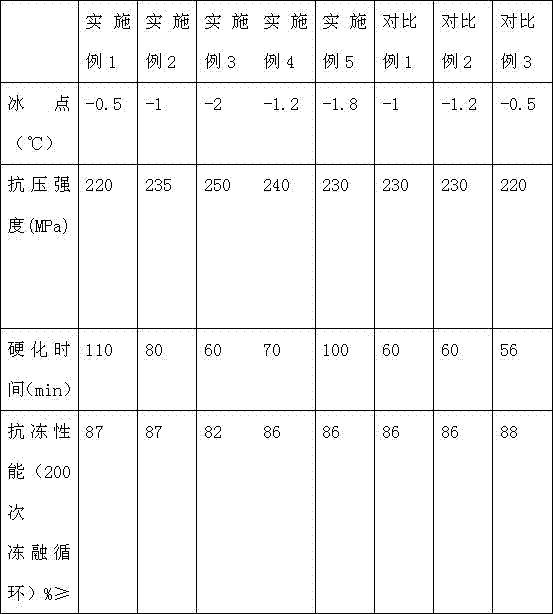

Examples

Embodiment 1

[0026] A concrete early strength agent, comprising 1 part of sodium chloride, 1 part of sodium nitrite, 10 parts of sodium sulfate, 3 parts of calcium chloride, 2 parts of urea, 5 parts of methacrylic acid, 1 part of silane, and 1 part of calcium gluconate , 1 part of triisopropanolamine, 5 parts of fatty acid glycerides, 50 parts of polycarboxylate superplasticizer, 2 parts of finely ground cement stone of 0.3 μm.

[0027] The above-mentioned concrete accelerator is prepared through the following steps:

[0028] Step 1: According to the molar ratio, methallyl polyoxyethylene ether, maleic anhydride and vinyl propionate = 0.05:0.3:0.1 weigh methallyl polyoxyethylene ether, maleic anhydride And vinyl propionate, be placed in the reactor and add the hydrogen peroxide that massfraction is 5% as initiator;

[0029] Step 2: Let the material in the reactor react under the conditions of 80°C and 3MPa to obtain a polycarboxylate water reducer;

[0030] Step 3: Weigh 2 parts of 0.3 μ...

Embodiment 2

[0032] A concrete early strength agent, comprising 1.5 parts of sodium chloride, 1.5 parts of sodium nitrite, 13 parts of sodium sulfate, 4 parts of calcium chloride, 3 parts of urea, 8 parts of methacrylic acid, 1.5 parts of silane, and 2 parts of calcium gluconate , 2 parts of triisopropanolamine, 6 parts of fatty acid glycerides, 60 parts of polycarboxylate superplasticizer, 2.5 parts of finely ground cement stone of 0.3 μm.

[0033] The above-mentioned concrete accelerator is prepared through the following steps:

[0034] Step 1: According to the molar ratio, methallyl polyoxyethylene ether, maleic anhydride and vinyl propionate = 0.05:0.3:0.1 weigh methallyl polyoxyethylene ether, maleic anhydride And vinyl propionate, be placed in the reactor and add the hydrogen peroxide that massfraction is 5% as initiator;

[0035] Step 2: Let the material in the reactor react under the conditions of 80°C and 3MPa to obtain a polycarboxylate water reducer;

[0036]Step 3: Weigh 2.5 ...

Embodiment 3

[0038] A concrete early strength agent, comprising 2 parts of sodium chloride, 2 parts of sodium nitrite, 15 parts of sodium sulfate, 4 parts of calcium chloride, 6 parts of urea, 12 parts of methacrylic acid, 3 parts of silane, and 5 parts of calcium gluconate , 5 parts of triisopropanolamine, 8 parts of fatty acid glycerides, 80 parts of polycarboxylate superplasticizer, 4 parts of finely ground cement stone of 0.3 μm.

[0039] The above-mentioned concrete accelerator is prepared through the following steps:

[0040] Step 1: According to the molar ratio, methallyl polyoxyethylene ether, maleic anhydride and vinyl propionate = 0.05:0.3:0.1 weigh methallyl polyoxyethylene ether, maleic anhydride And vinyl propionate, be placed in the reactor and add the hydrogen peroxide that massfraction is 5% as initiator;

[0041] Step 2: Let the material in the reactor react under the conditions of 80°C and 3MPa to obtain a polycarboxylate water reducer;

[0042] Step 3: Weigh 4 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com