Processing method and corresponding processing system for chemical nickel plating waste liquid containing nitric acids

The technology of chemical nickel plating and treatment method is applied in the treatment of chemical nickel plating waste liquid and the treatment system field of chemical nickel plating waste liquid, which can solve the problems of resource waste, waste water failing to meet the national first-class discharge standard, environmental pollution, etc. To achieve the effect of small environmental pollution, reduced production and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

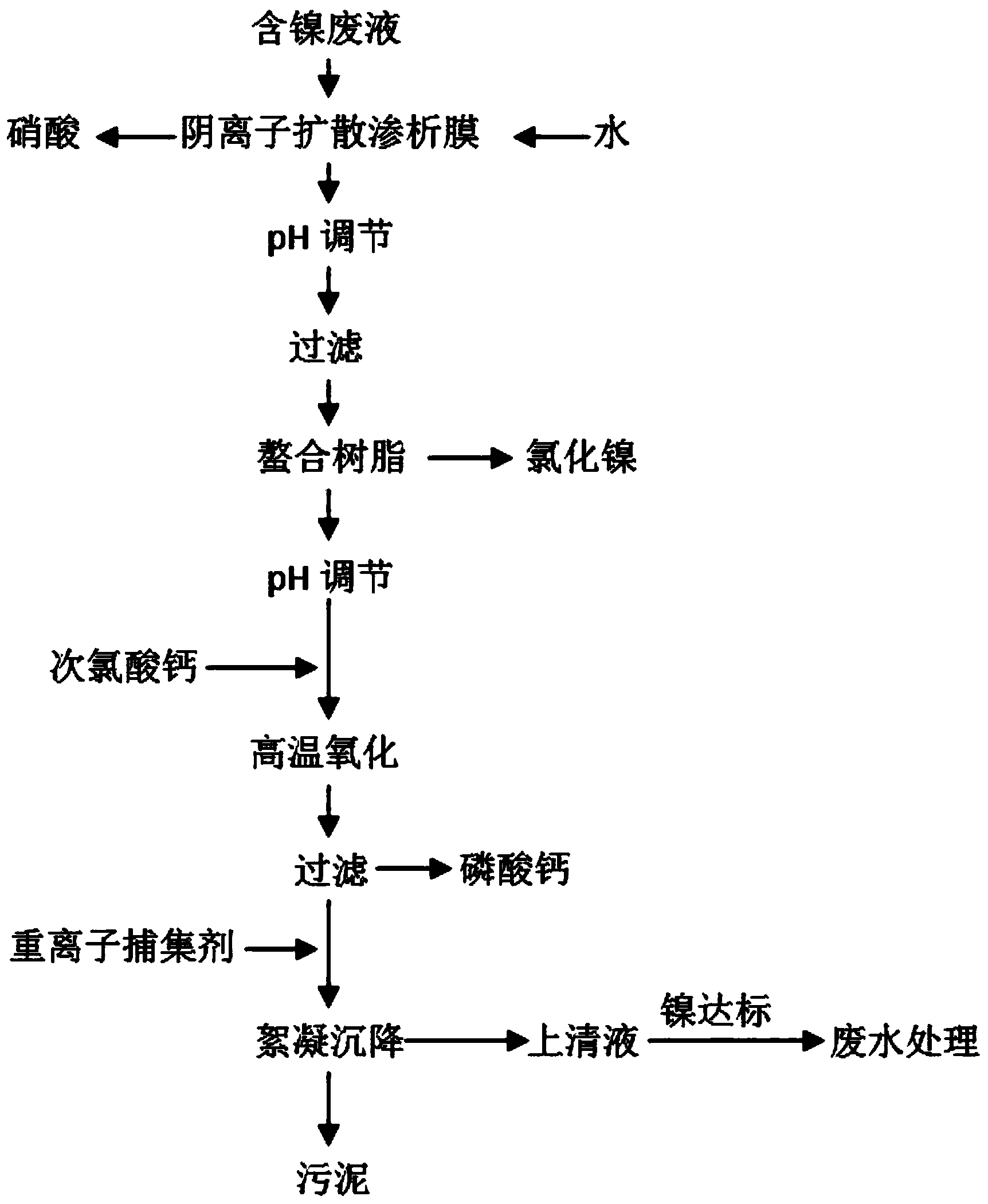

[0034] A treatment method for electroless nickel plating waste liquid containing nitric acid, aimed at the comprehensive treatment of electroless nickel plating waste liquid containing high concentration nitric acid, can realize the resource recovery and utilization of nitric acid, reduce the generation of nitrogen-containing waste water, and Ni in the waste water after treatment Content figure 1 :

[0035] (1) Filtrate the nickel-containing waste liquid containing the nitric acid of mass fraction 10%~30%, remove mechanical impurity;

[0036] (2) The nickel-containing waste liquid treated in step (1) is separated from nitric acid through the anion diffusion dialysis membrane, and the nickel-containing waste liquid and water are passed through the diffusion dialysis membrane at the same time, and the volume ratio of the nickel-containing waste liquid to water is 1:1 , the speed is 8~10L / min;

[0037] (3) Use 10%-50% sodium hydroxide solution to adjust the pH of the nickel-cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com