Method for treating lithium nickel manganese cobalt oxide ternary waste

A technology of nickel cobalt lithium manganate and a treatment method, which is applied to cobalt sulfate, nickel halide, electrical components, etc., can solve the problems of solid waste pollution, large amount of waste water, health hazards, etc. The effect of low cost and low waste water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

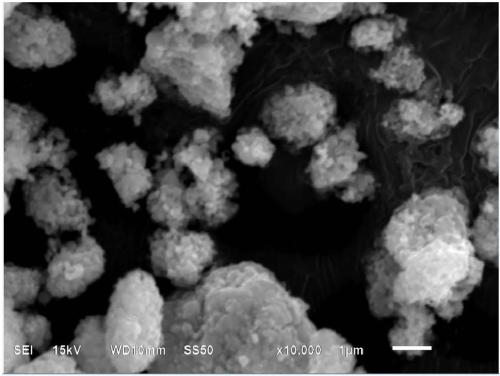

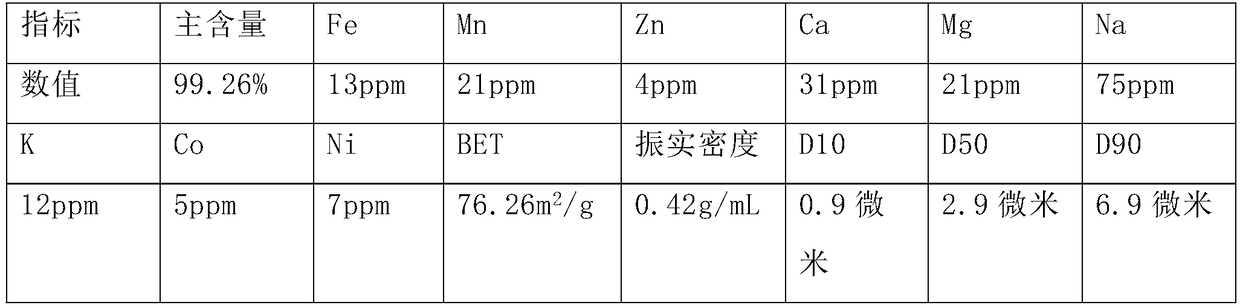

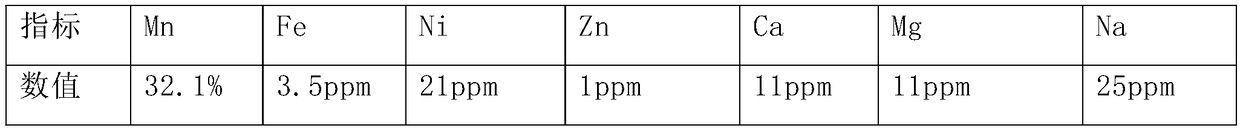

Image

Examples

Embodiment 1

[0051] A kind of processing method of nickel-cobalt lithium manganate ternary waste material, it is the following steps:

[0052] (1) Add nickel-cobalt lithium manganate ternary waste to alkaline solution, soak for 5 hours, soak at 59°C, filter to obtain aluminum-containing solution and filter residue, dry and sieve the filter residue after washing, and put the underscreen into Carry out reduction in the reduction furnace, the reduction temperature is 420°C, the reduction time is 8 hours, and then the cooling material is discharged after cooling to obtain the cooling material;

[0053] (2) Add the cooling material to hot pure water and stir, maintain the temperature of the stirring process at 93°C, and stir for 3.5 hours to separate the solid and liquid to obtain the lithium-containing filtrate and filter residue. After the filter residue is washed, the washing liquid and the lithium-containing filtrate mix;

[0054] (3) adding sulfuric acid solution to slurry the washed filt...

Embodiment 2

[0077] A kind of processing method of nickel-cobalt lithium manganate ternary waste material, it is the following steps:

[0078] (1) Add nickel-cobalt lithium manganate ternary waste to alkaline solution, soak for 4.5 hours, soak at 58°C, filter to obtain aluminum-containing solution and filter residue, dry and sieve the filter residue after washing, and put the undersieve into Carry out reduction in the reduction furnace, the reduction temperature is 415°C, the reduction time is 8 hours, and then the cooling material is discharged after cooling to obtain the cooling material;

[0079] (2) Add the cooling material to hot pure water and stir, maintain the temperature of the stirring process at 93°C, and stir for 3.5 hours to separate the solid and liquid to obtain the lithium-containing filtrate and filter residue. After the filter residue is washed, the washing liquid and the lithium-containing filtrate mix;

[0080] (3) adding sulfuric acid solution to slurry the washed fil...

Embodiment 3

[0102] A kind of processing method of nickel-cobalt lithium manganate ternary waste material, it is the following steps:

[0103] (1) Add nickel-cobalt lithium manganate ternary waste to alkaline solution, soak for 4.8 hours, soak at 63°C, filter to obtain aluminum-containing solution and filter residue, dry and sieve the filter residue after washing, and put the undersize into Carry out reduction in the reduction furnace, the reduction temperature is 425°C, the reduction time is 8 hours, and then the cooling material is discharged after cooling to obtain the cooling material;

[0104] (2) Add the cooling material to hot pure water and stir, maintain the temperature of the stirring process at 93°C, and stir for 3.5 hours to separate the solid and liquid to obtain the lithium-containing filtrate and filter residue. After the filter residue is washed, the washing liquid and the lithium-containing filtrate mix;

[0105] (3) adding sulfuric acid solution to slurry the washed filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com