NCM613 single crystal type positive electrode material and preparation method thereof

A positive electrode material and single crystal technology, applied in the field of NCM613 single crystal positive electrode material and its preparation, can solve problems such as high cobalt content and achieve excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

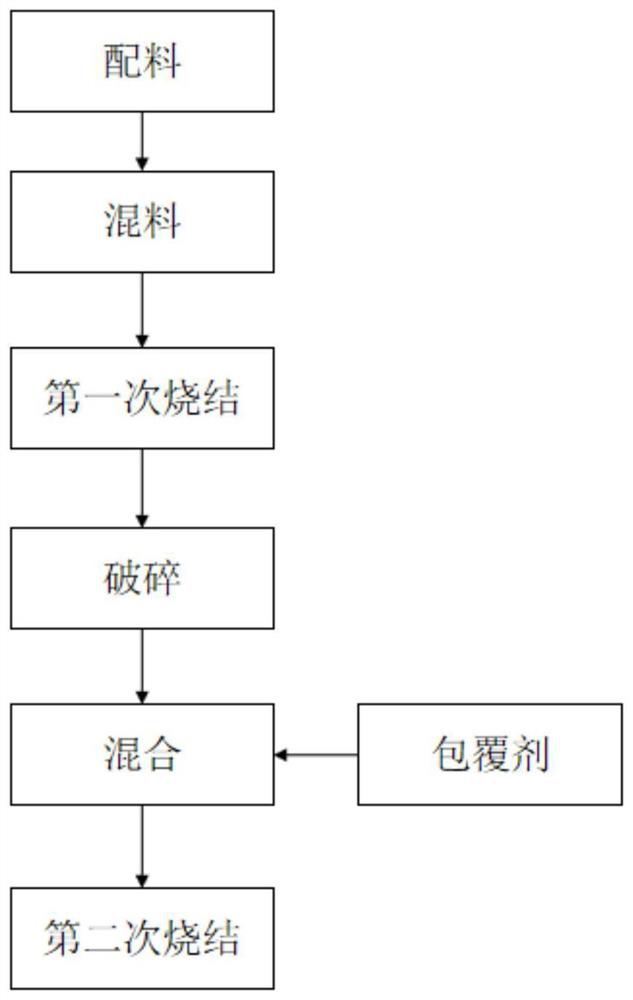

[0031] One aspect of the present invention provides a preparation method of NCM613 single crystal type cathode material, the flow chart is as follows figure 1 As shown, the method includes the following steps:

[0032] (1) Weigh the raw materials according to the ratio, and combine part of the lithium hydroxide and precursor Ni 0.6 Co 0.1 Mn 0.3 (OH) 2 , Add the additives and the remaining lithium hydroxide into the mixer in turn, and then mix the materials to obtain the mixture;

[0033] (2) Put the mixture obtained in step (2) into a sagger, cut into pieces, and then transfer the sagger to a sintering furnace for the first sintering;

[0034] (3) The material obtained by the first sintering in step (2) is crushed, then mixed with the coating agent, and then transferred to the sintering furnace for the second sintering;

[0035] Wherein, the precursor Ni in the raw material 0.6 Co 0.1 Mn 0.3 (OH) 2 The molar ratio to lithium hydroxide is 1: (1.05-1.1).

[0036] In the method of the pre...

Embodiment 1

[0068] (1) Weigh the raw materials according to the ratio, the precursor Ni 0.6 Co 0.1 Mn 0.3 (OH) 2 (Dmin≥1.2μm, S content is 260ppm) and the molar ratio of lithium hydroxide is 1:1.06; half the weight of lithium hydroxide, precursor Ni 0.6 Co 0.1 Mn 0.3 (OH) 2 , 1000ppm of zirconia additive and the other half of the weight of lithium hydroxide were added to the VC mixer in turn, and then mixed (mixing procedure is 150rpm mixing 5min→300rpm mixing 5min→450rpm mixing 5min→600rpm mixing 5min →800rpm mixing for 20min) to obtain a mixture;

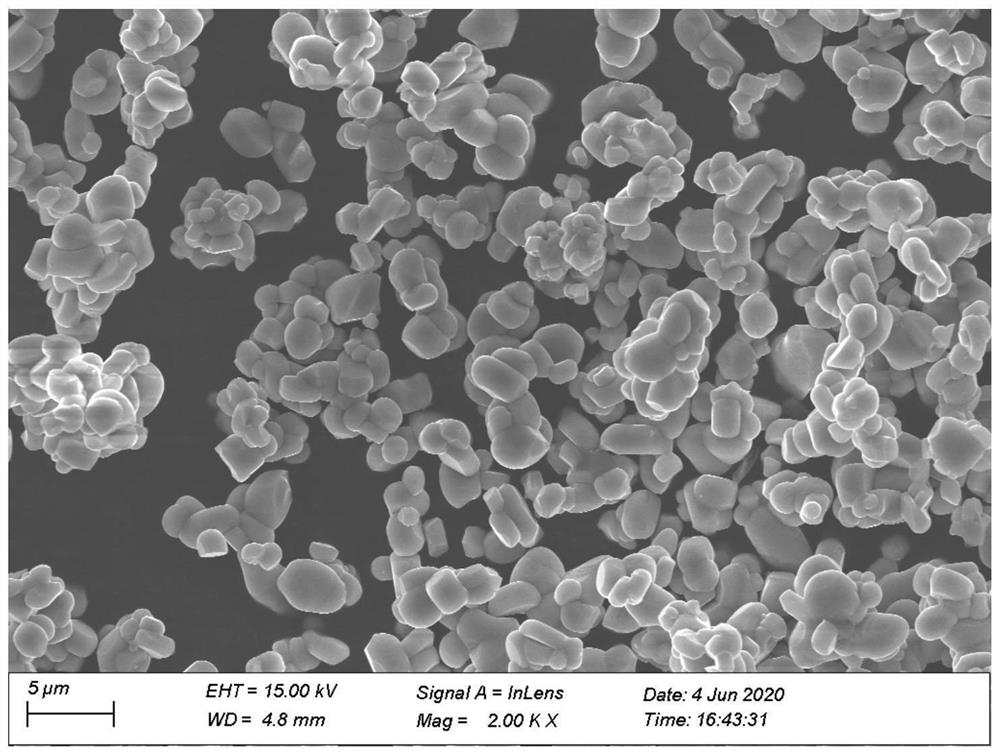

[0069] (2)) Weigh 1.5kg of the mixture obtained in step (2) into the sagger, and cut into pieces (the cutting method is 3*3), and then transfer the sagger to the muffle furnace for the first time Sintering includes three sintering stages. The sintering conditions of the first stage include: heating rate of 3℃ / min, sintering temperature of 500℃, and sintering time of 240min. The sintering conditions of the second stage include: heating rate of 1.5...

Embodiment 2

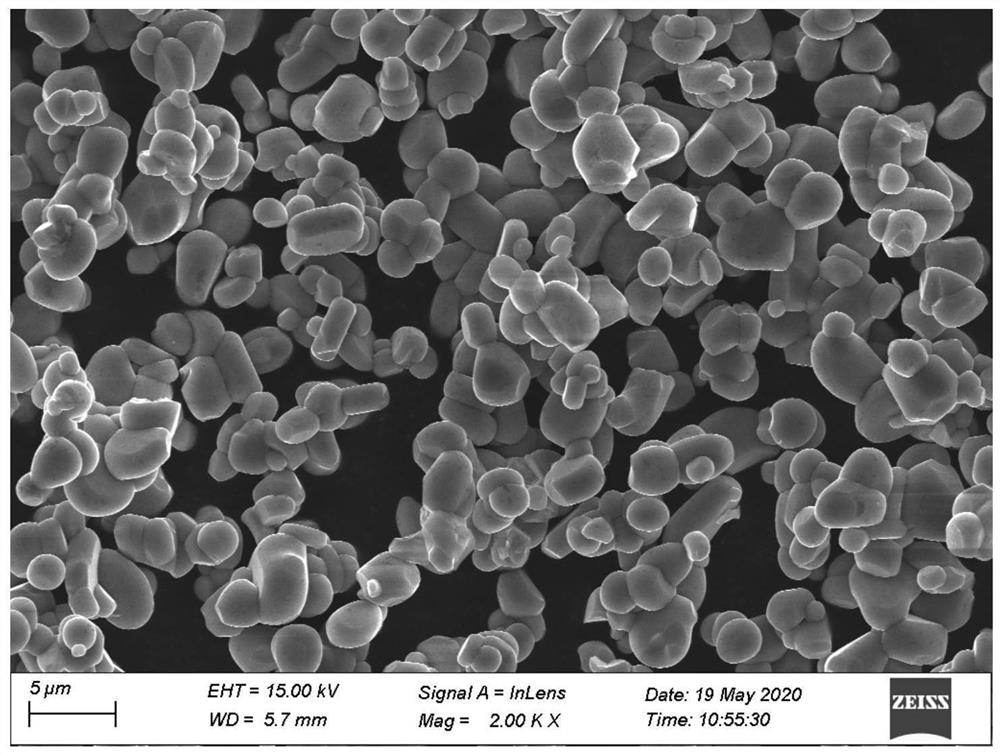

[0072] (1) Weigh the raw materials according to the ratio, the precursor Ni 0.6 Co 0.1 Mn 0.3 (OH) 2 (Dmin≥1.4μm, S content is 250ppm) and the molar ratio of lithium hydroxide is 1:1.09; half the weight of lithium hydroxide, precursor Ni 0.6 Co 0.1 Mn 0.3 (OH) 2 , Additives (1000ppm of zirconia additive, 200ppm of MgO, 200ppm of CaF 2 , 200ppm of H 3 BO 3 , 200ppm SrO and 200ppm Al 2 O 3 ) And the other half of the weight of lithium hydroxide are sequentially added to the VC mixer, and then mixed (mixing procedure is 150rpm mixing 5min→300rpm mixing 5min→450rpm mixing 5min→600rpm mixing 5min→800rpm mixing 20min ) To get the mixture;

[0073] (2) Weigh 1.5kg of the mixture obtained in step (2) into the sagger, and cut into pieces (the cutting method is 3*3), and then transfer the sagger to the muffle furnace for the first sintering It includes three sintering stages. The sintering conditions of the first stage include: heating rate of 2℃ / min, sintering temperature of 550℃, and sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com