Cemented tungsten carbide alloy material with gradient cobalt content

A technology of cobalt content and tungsten carbide, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of increased manufacturing cost and poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

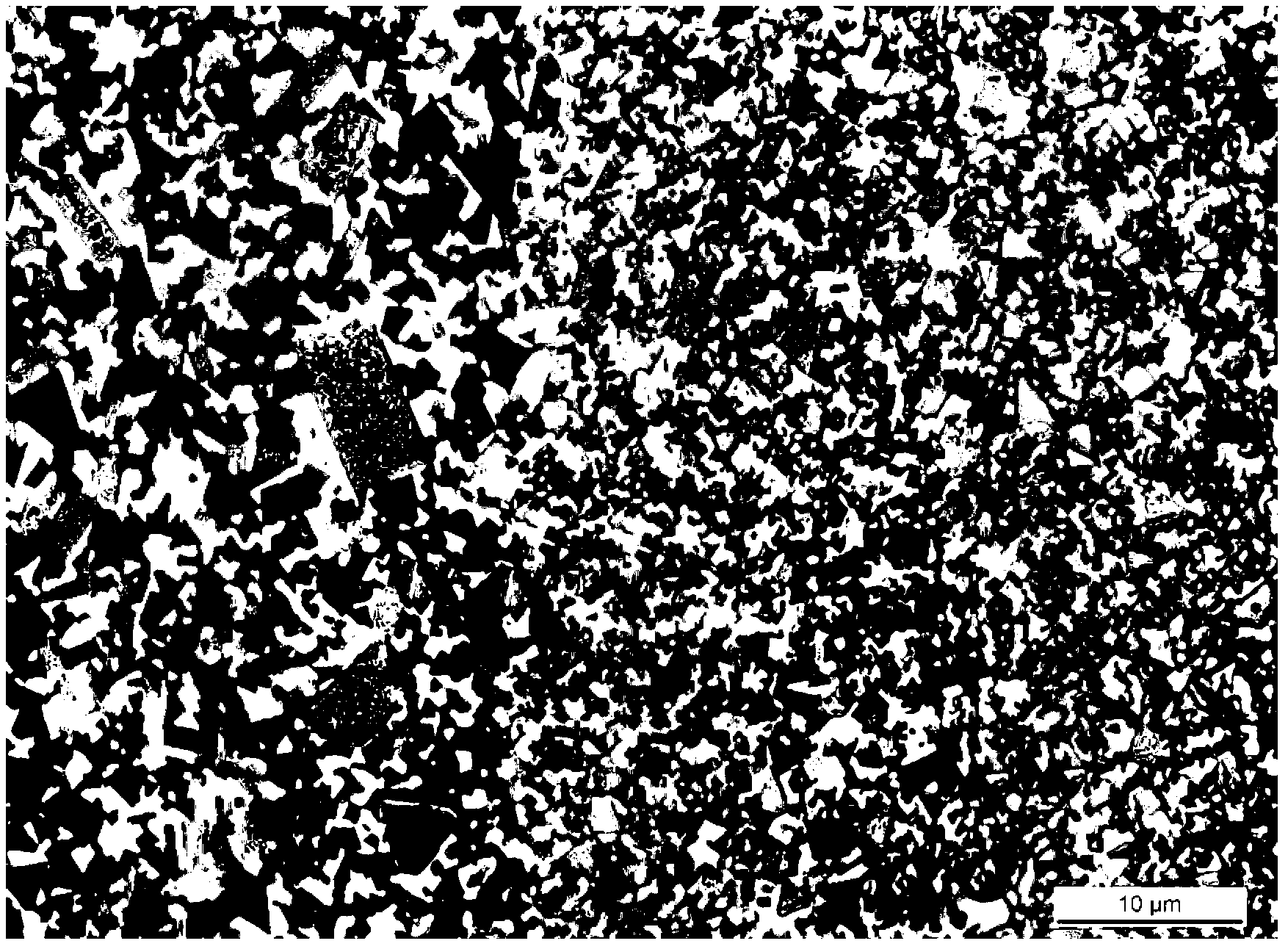

Embodiment 1

[0051] Raw material ratio: the percentage of the total cemented carbide mass.

[0052] WC 90%

[0053] Co 9.7%

[0054] TaC 0.3%,

[0055] 1. To prepare the mixture, mix 35Kg of the above raw materials with a ball ratio of 4:1, wine material 250ml / Kg, and ball mill for 30 hours. The raw materials are graded, with coarse grade: 85%, medium grade: 10%, and fine grade: 5%.

[0056] 2. The size of the sample block is 7X5.5X25mm, and it is pressed by a hydraulic press, and the pressure of the sample block is 5MPa.

[0057] 3. The sintering temperature after pressing is 1450°C, and H is added during sintering. 2 1.0m 3 / h, keep warm at 1400°C for 30 minutes during sintering, keep warm for 30 minutes at 1500°C, and then cool down. Cemented carbide with graded cobalt content is obtained.

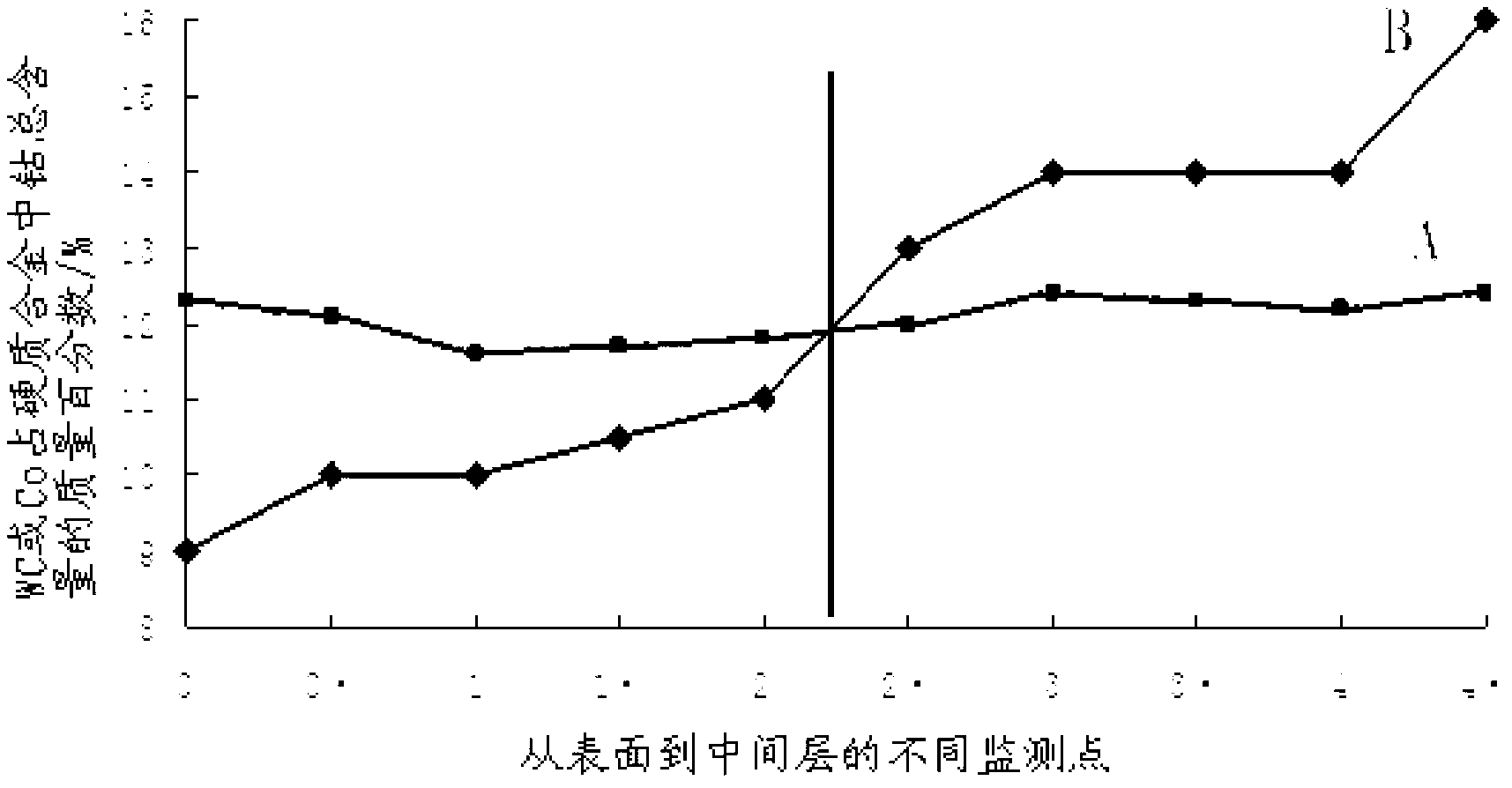

[0058] The change curve of the hard alloy from the surface cobalt content that is WC-Co9% to the middle layer cobalt content that is WC-Co 16% cobalt content accounts for the total cobalt elem...

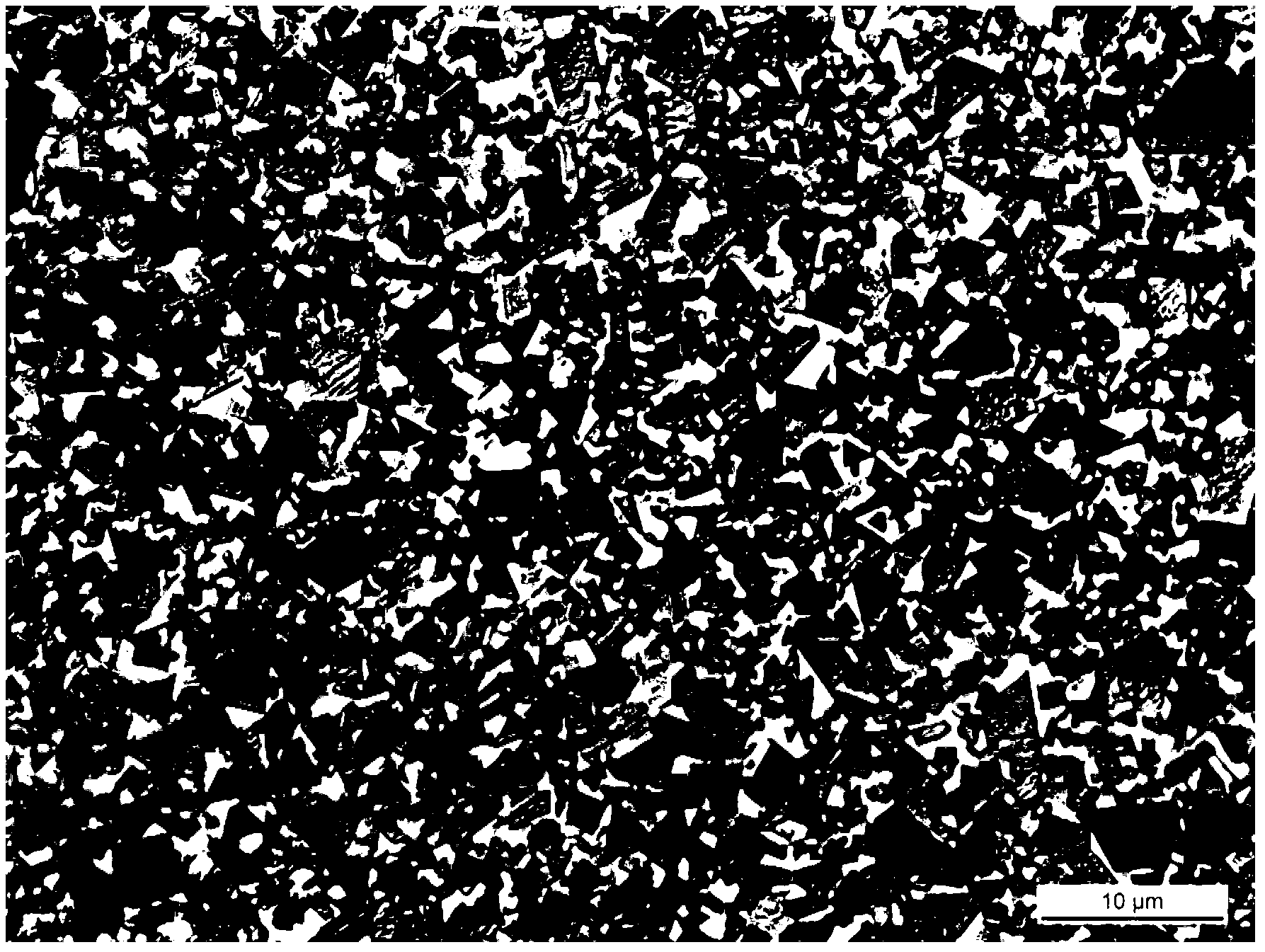

Embodiment 2

[0060] Raw material ratio: the percentage of the total cemented carbide mass.

[0061] WC 90%

[0062] Co 9.9%

[0063] TaC 01%,

[0064] 1. To prepare the mixture, mix 35Kg of the above raw materials with a ball ratio of 4:1, wine material 250ml / Kg, and ball mill for 30 hours. The raw materials are graded, with coarse grade: 75%, medium grade: 15%, and fine grade: 5%.

[0065] 2. The size of the sample block is 7X5.5X25mm, and it is pressed by a hydraulic press, and the pressure of the sample block is 12MPa.

[0066] 3. The sintering temperature after pressing is 1400°C, and H is added during sintering. 2 1.0m 3 / h, keep warm at 1400°C for 30 minutes during sintering, keep warm for 30 minutes at 1500°C, and then cool down. Cemented carbide with graded cobalt content is obtained.

[0067] Some embodiments of the present invention graded cobalt cemented tungsten carbide materials may be used in the manufacture of cutting tools. In particular, tools that may be used for m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com