Ni-Cu-P ternary alloy coating serving as welding spot reaction barrier layer and electroplating preparation technology thereof

A ternary alloy and preparation technology, applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of difficult maintenance of plating solution components, low plating solution life, high operating temperature, etc., to achieve reduced content, plating The effect of stabilizing the liquid composition and reducing the internal stress of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

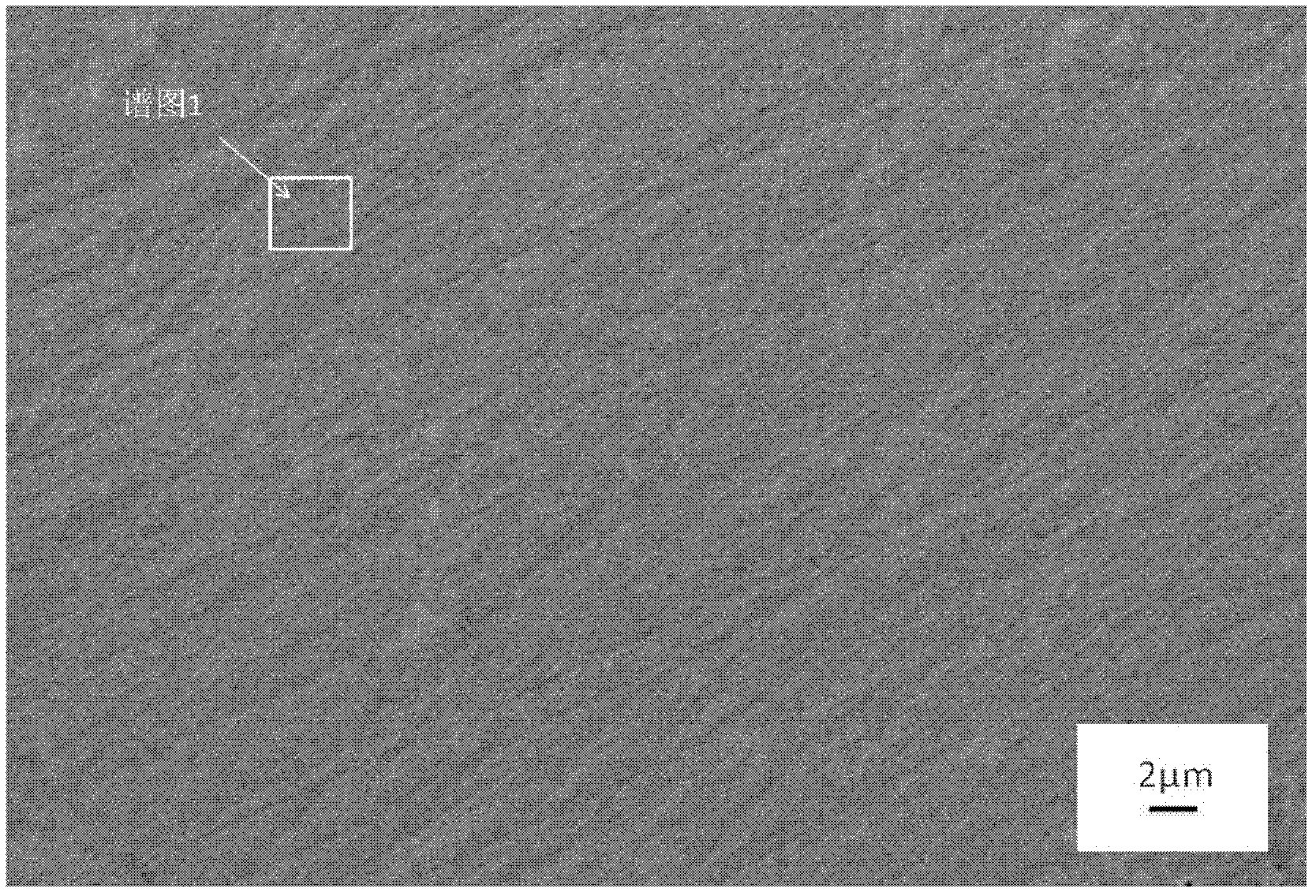

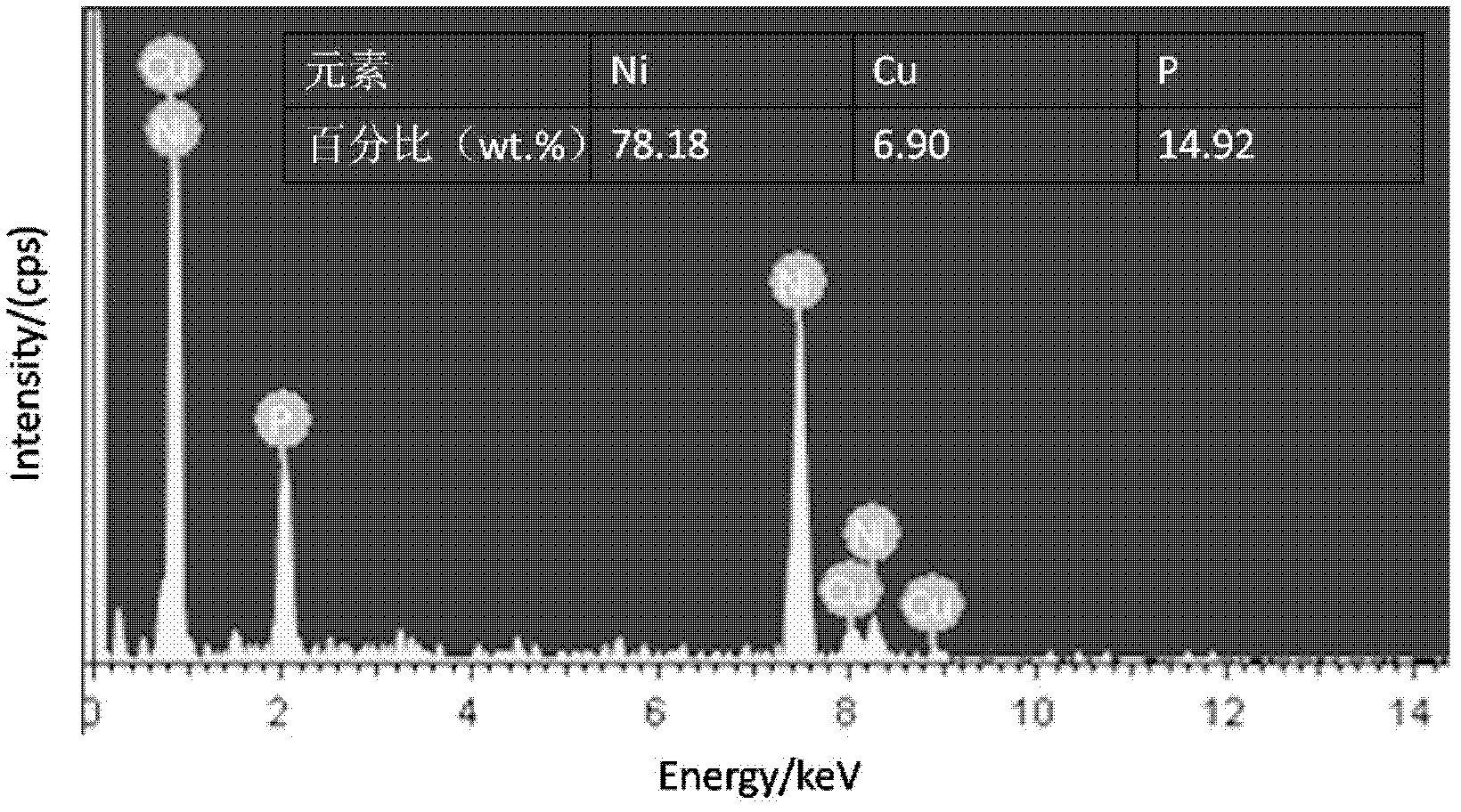

[0024] A double-pulse electroplating process for preparing Ni-Cu-P alloy coatings. The metallized Si chip or Cu sheet is used as the cathode as the deposition substrate of the Ni-Cu-P alloy, while the anode uses a Pt sheet. After the above-mentioned cathode and anode sheets are cleaned with distilled water, alcohol and degreased with acetone, they are placed in the electroplating solution and fed with forward / reverse double pulse current for double pulse electroplating. The electroplating solution is an aqueous solution, and its chemical composition is: citric acid dihydrate Trisodium 0.58mol / L, triammonium citrate 0.08mol / L, nickel sulfate hexahydrate 0.46mol / L, nickel chloride hexahydrate 0.13mol / L, copper sulfate pentahydrate 0.0008mol / L, sodium hypophosphite 0.33mol / L, boric acid 0.65mol / L and saccharin 0.005mol / L, trisodium citrate dihydrate, triammonium citrate, nickel sulfate hexahydrate, nickel chloride hexahydrate, copper sulfate pentahydrate, sodium hypophosphite, bo...

Embodiment 2

[0029] The preparation method of this embodiment is the same as that of Example 1, except that copper sulfate pentahydrate is 0.0002 mol / L, sodium hypophosphite is 0.28 mol / L, and the resulting coating composition is 89.63% Ni, 3.13% Cu, and 7.24% P.

Embodiment 3

[0031]The preparation method of this embodiment is the same as that of Example 1, except that copper sulfate pentahydrate is 0.0015 mol / L, sodium hypophosphite is 0.37 mol / L, and the obtained coating composition is 71.36% Ni, 9.72% Cu, and 18.92% P.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com