Method for preparing corrosion-resistant high-performance sintered neodymium iron boron magnets

A NdFeB, high-performance technology, used in inductor/transformer/magnet manufacturing, electrical components, circuits, etc., can solve problems such as difficulties, limiting the application of NdFeB materials, and increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

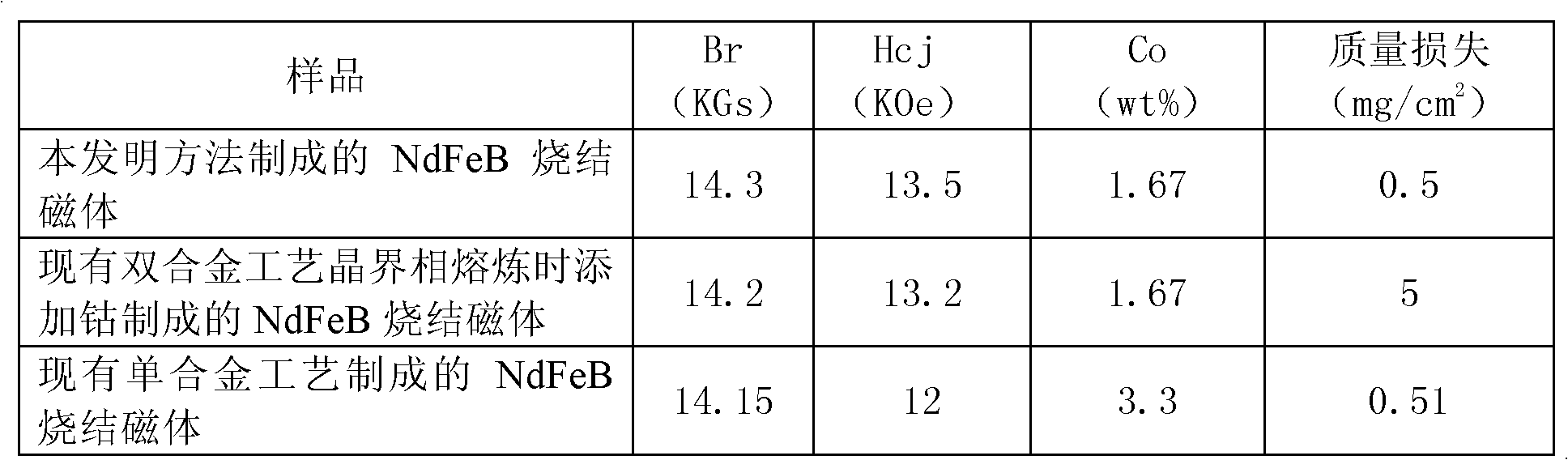

Examples

Embodiment 1

[0020] The method for preparing a corrosion-resistant high-performance sintered NdFeB magnet of the present invention comprises the following steps:

[0021] 1) The main phase alloy material with a purity greater than 99% is prepared according to the weight ratio of Nd23%, Pr6%, Fe69.65%, Cu0.1%, Ga0.1%, Al0.1%, and B1.05%. The 200Kg / time strip billet is melted in the continuous casting furnace, and the main phase alloy sheet is cast at a roll speed of 1.5m / s, and the thickness of the alloy sheet is 0.2-0.3mm.

[0022] 2) The grain boundary phase alloy material with a purity greater than 99% is formulated according to the following weight ratios: Nd18%, Pr8%, Dy20%, Fe50.9%, Cu0.4%, Ga0.2%, Al2%, B0.5% , using a rapid quenching process with a copper roll speed of 20m / s to make a rapidly quenched grain boundary phase alloy strip, and the thickness of the alloy strip is 40-60μm.

[0023] 3) The main phase alloy flakes and the grain boundary phase alloy strips are powdered separ...

Embodiment 2

[0029] The method for preparing a corrosion-resistant high-performance sintered NdFeB magnet of the present invention comprises the following steps:

[0030] 1) The main phase alloy material with a purity greater than 99% is prepared according to the weight ratio of Nd23%, Pr6%, Fe69.65%, Cu0.1%, Ga0.2%, and B1.05%. The slab is melted in a continuous casting furnace, and cast at a roll speed of 1m / s to form a main phase alloy sheet with a thickness of 0.1-0.4mm.

[0031] 2) The grain boundary phase alloy material with a purity greater than 99% is prepared according to the following weight ratios: Nd18%, Pr8%, Dy20%, Fe50.9%, Cu0.6%, Al2%, B0.5%, using 15m / s The rapid quenching process of the red copper roll speed is used to make the rapidly quenched grain boundary phase alloy strip, and the thickness of the alloy strip is 40-60μm.

[0032] 3) The main phase alloy flakes and the grain boundary phase alloy strips are powdered separately: the main phase alloy flakes are crushed ...

Embodiment 3

[0038] The method for preparing a corrosion-resistant high-performance sintered NdFeB magnet of the present invention comprises the following steps:

[0039] 1) The main phase alloy material with a purity greater than 99% is prepared according to the weight ratio of Nd23%, Pr6%, Fe69.65%, Cu0.1%, Al0.2%, and B1.05%. The slab is melted in a continuous casting furnace and cast at a roll speed of 2m / s to form a main phase alloy sheet with a thickness of 0.1-0.4mm.

[0040] 2) The grain boundary phase alloy material with a purity greater than 99% is prepared according to the following weight ratios: Nd18%, Pr8%, Dy20%, Fe50.9%, Ga0.6%, Al2%, B0.5%, using 30m / s The rapid quenching process of the red copper roll speed is used to make the rapidly quenched grain boundary phase alloy strip, and the thickness of the alloy strip is 30-80μm.

[0041] 3) The main phase alloy flakes and the grain boundary phase alloy strips were powdered separately: the main phase alloy flakes were crushed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com