Mesoporous Molecular Sieve Composite Laser Direct Structuring Materials and Its Application

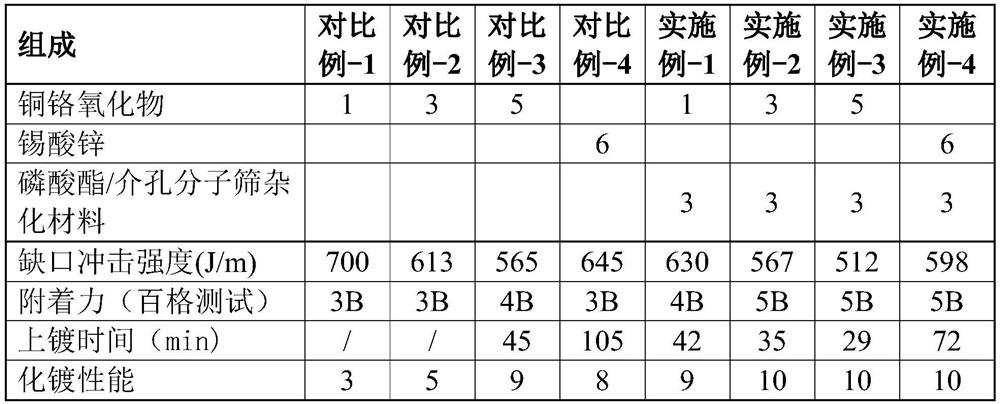

A technology of laser direct structuring and mesoporous molecular sieve, which is applied in the compounding modification of laser direct structuring additives and the preparation of laser direct structuring materials. Achieve the effects of shortening the plating time, improving the bonding strength, and improving the carbon forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

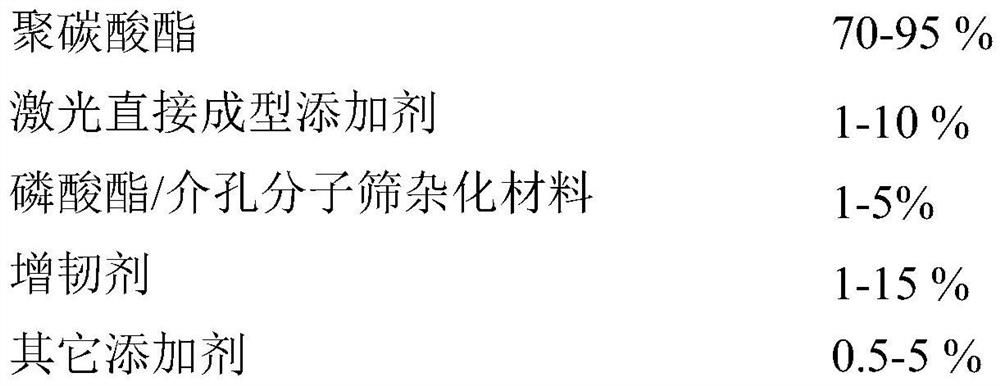

Method used

Image

Examples

Embodiment 1-4

[0051] First, dry the mesoporous molecular sieve MCM-41 (average pore size: 3.4nm; particle size: 200-1000nm) at 200°C and vacuum conditions of <0.1MPa for 2 hours, and at the same time, bisphenol A bis(diphenyl phosphate) 100°C for preheating. Under the vacuum condition of pressure<0.1MPa, mix 100 parts (parts by weight) of mesoporous molecular sieve and 15 parts (parts by weight) of bisphenol-A-diphenyl phosphate, heat up to 120°C and stir for 2 hours, and the obtained phosphoric acid ester / mesoporous molecular sieve hybrid material for use.

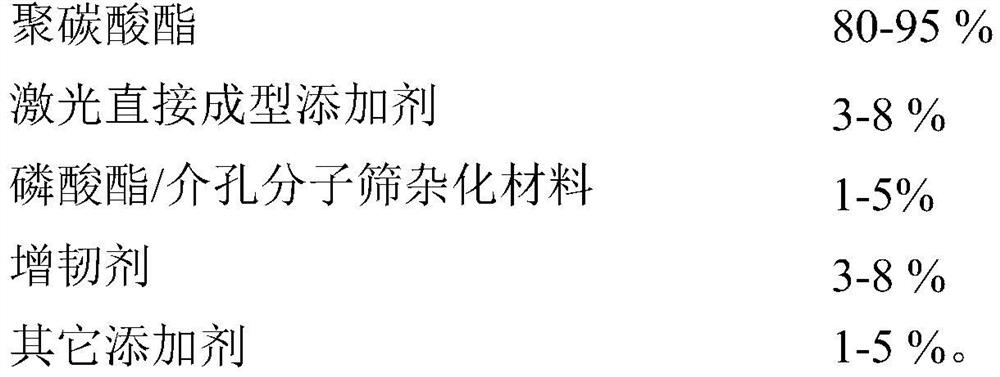

Embodiment 1

[0052] In embodiment 1, raw material total amount is 6kg, and by weight percentage, component is as follows:

[0053] Component weight percentage polycarbonate 90% Laser Direct Structuring Additive A 1% Phosphate ester / mesoporous molecular sieve hybrid materials 3% Toughener 5% other additives 1%

Embodiment 2

[0054] In embodiment 2, raw material total amount is 5.5kg, and by weight percentage, component is as follows:

[0055] Component weight percentage polycarbonate 88% Laser Direct Structuring Additive A 3% Phosphate ester / mesoporous molecular sieve hybrid materials 3% Toughener 5% other additives 1%

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com