a dental implant

An implant and body technology, used in implants, dentistry, prosthetics, etc., can solve the problems of slow and weak osseointegration, and achieve the effect of promoting adhesion, uniform friction and increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

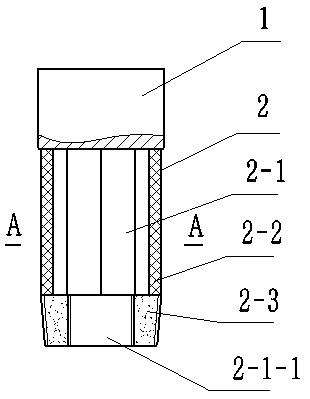

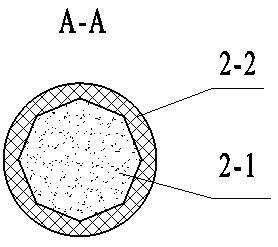

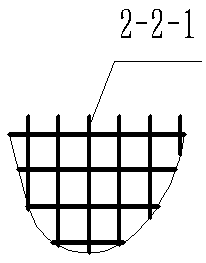

[0025] An artificial dental implant consists of a head 1 and a body 2. The body 2 includes a mandrel 2-1, a sleeve 2-2, and an anchoring part 2-3. The sleeve 2-2 is sleeved on the mandrel 2-2. 1, the inner surface of the sleeve 2-2 is attached to the outer surface of the mandrel 2-1, such as figure 2 As shown, the outer periphery of the cross-section of the mandrel and the inner periphery of the sleeve 2-2 are regular octagons, the anchoring part 2-3 and the end 2-1-1 of the mandrel 2-1 are fixed by threaded connection, and the sleeve 2 -2 is fixed in the axial direction by the head 1 and the anchoring part 2-3, the anchoring part 2-3 has a threaded outer surface, and a wire mesh sleeve body made of cold-drawn titanium wire with a diameter of 0.1mm is selected, which is porous The pore diameter of titanium is 220 μm, and the pores are interpenetrated. Take 10 three-dimensional bodies of the same size with a volume not greater than 1 cubic millimeter on the porous titanium, we...

Embodiment 2

[0028]This embodiment is similar to Embodiment 1, except that the outer periphery of the cross section of the mandrel 2-1 and the inner periphery of the sleeve 2-2 are ellipses, and the ratio of the major axis to the minor axis of the ellipse is 1.2:1. The porous metal material of the sleeve is made of niobium, and the sleeve 2-2 is prepared by an additive manufacturing process. The aperture of the porous niobium is 140±5 μm, and the protruding edge length on the outer surface of the sleeve 2-2 is 60 μm-70 μm (the length of the edge is the aperture 43%-50%), the additive manufacturing process is: use niobium powder with a particle size of 5μm-10μm, use CAD software to shape, make a square shape with an edge of 140μm, a edge diameter of 60μm, and a unit of 12 edges The frame-shaped porous material model, import the porous material model into the laser additive manufacturing system, scan according to the CAD software modeling, the scanning speed is 200mm / min, the laser power is 9...

Embodiment 3

[0031] This embodiment is similar to Embodiment 1, except that the outer periphery of the cross section of the mandrel 2-1 and the inner periphery of the sleeve 2-2 are regular 12-sided, and the porous metal material of the sleeve is made of tantalum. Sleeve 2-2 was prepared by material manufacturing process, the pore diameter of porous tantalum was 150±5μm, and the protruding edge length on the outer surface of sleeve 2-2 was 57μm-63μm (the length of the edge was 38%-42% of the pore diameter), additive manufacturing The process is: use tantalum powder with a particle size of 5 μm-10 μm and a purity of 99.99%, use CAD software to model, and make a square frame-shaped porous material model with an edge of 150 μm, a edge diameter of 50 μm, and a unit of 12 edges. , import the porous material model into the laser additive manufacturing system, scan according to the CAD software modeling, the scanning speed is 260mm / min, the laser power is 1500W, and the laser beam completes the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com