Preparation method of metal base nanometer composite powder material for added material manufacturing

A nanocomposite powder and additive manufacturing technology, applied in metal processing equipment, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as unfavorable large-scale preparation, increased melt viscosity, and complex processes , to achieve the effect of controlling harmful interface reactions, good fluidity, and fast combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

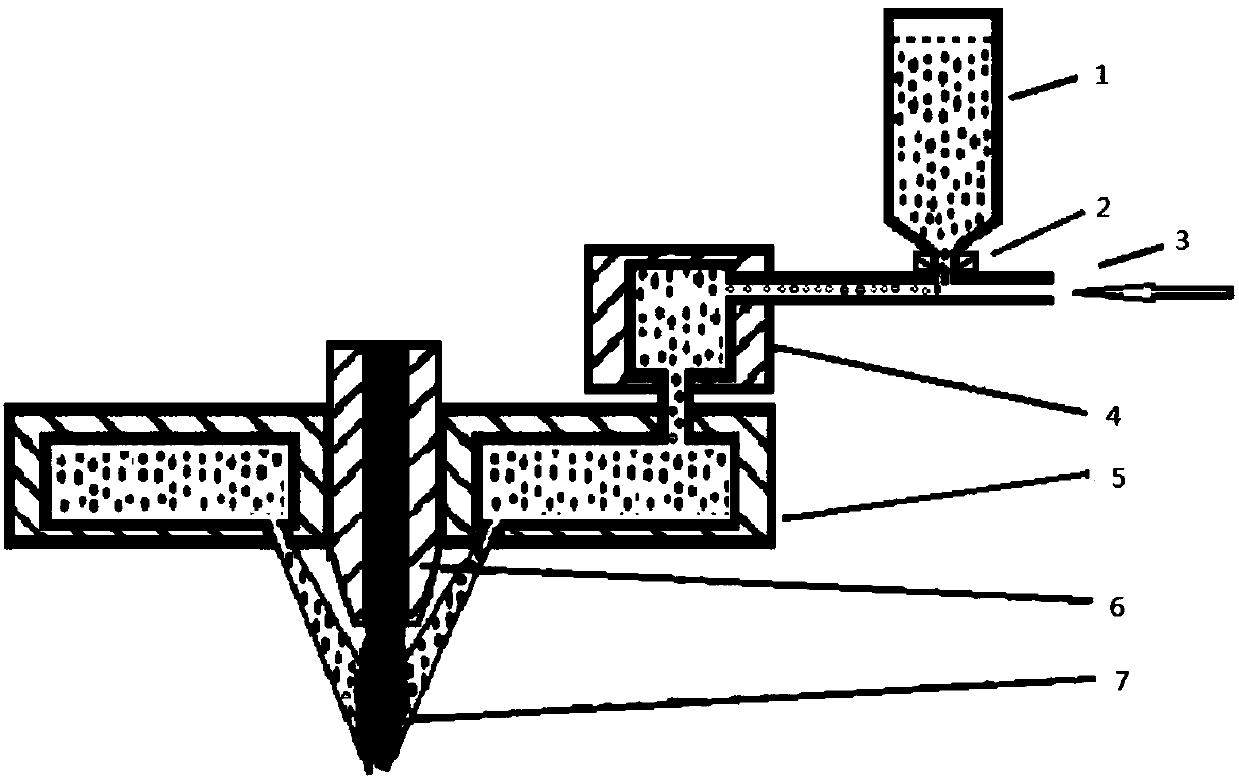

[0036] Adopt the following steps to prepare TiB2 / A356 aluminum-based composite powder:

[0037] Step 1: Take the metal material and put it into an intermediate frequency induction furnace for alloy melting;

[0038] Step 2: Put the nano-reinforced particles into the powder storage tank, the powder storage tank is connected with the high-pressure intake pipe, and the nano-reinforced particles are sent into the intake pipe through the delivery device;

[0039] Step 3: Turn on the high-pressure gas, and the air flow passes through the powder storage tank to carry nano-enhanced particles to form a solid-gas two-phase flow. Ultrasonic vibration is applied to the intake pipe to promote the uniform dispersion of nano-reinforced particles;

[0040] Step 4: After the high-pressure gas-solid two-phase flow passes through the atomizer, the molten metal flow is broken to form fine droplets carrying nano-reinforced particles, which are then spheroidized and solidified into powder.

[0041]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com