Engine crankcase oil and gas pre-filter

An oil-gas pre-filter and pre-filter technology, which is applied in the direction of engine components, crankcase ventilation, machines/engines, etc., can solve the problems of large oil-gas flow resistance, increased crankcase pressure, and low separation efficiency, so as to avoid oil-gas short circuit, The effect of accelerating the airflow velocity and avoiding the dead angle of oil return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

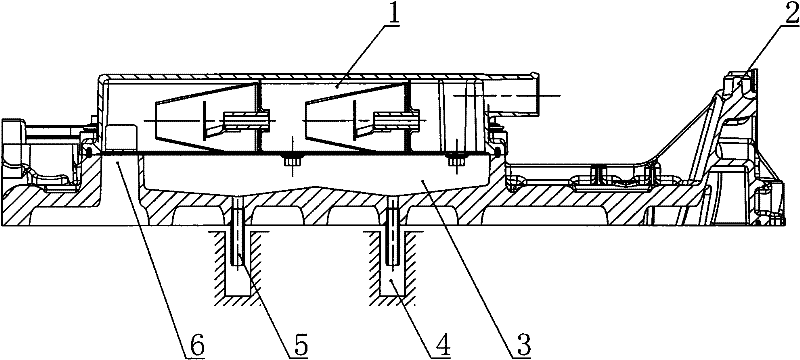

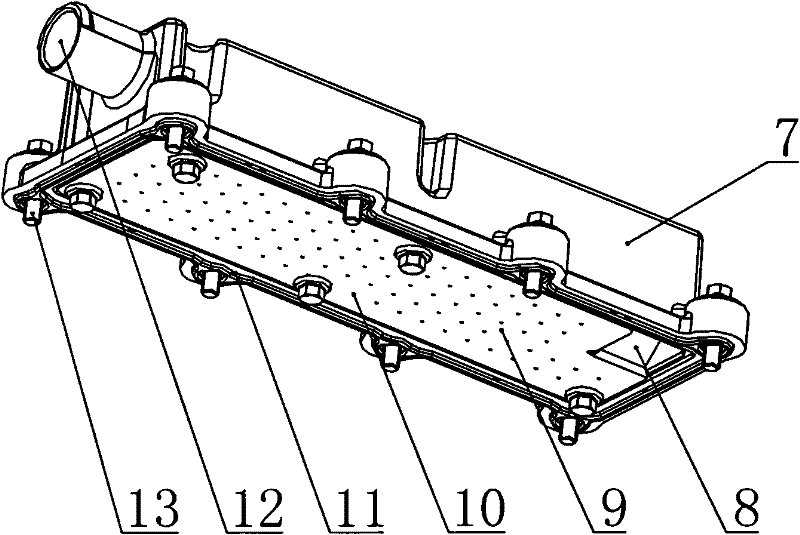

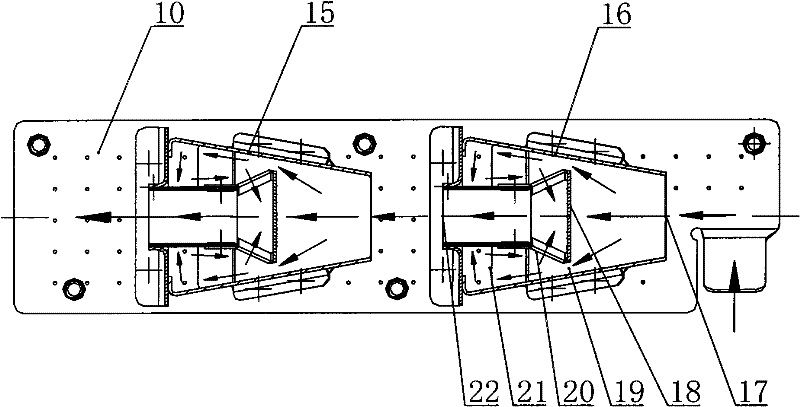

[0024] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

[0025] The filtering principle of the oil-gas pre-filter of the present invention is to use the principle that the airflow will accelerate when the airflow channel is narrowed from the width, that is, the flow velocity in the narrowed section will increase. as attached image 3 As shown, the oil-gas channel inside the labyrinth assembly of the present invention is narrowed from the width. At this time, the oil-gas flow accelerates, and the large-particle oil droplets have a large inertia due to their large mass. , so as to adhere to the inner wall of the pre-filter; the pre-filtration of small particles of oil droplets passing through the secondary labyrinth component will also be reduced to a certain extent.

[0026] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com