Electroplate liquid for jointly plating through hole and blind hole and electroplating method

A technology of electroplating solution and plating solution, which is applied in the direction of electrical components, printed circuits, and printed circuit manufacturing, can solve the problems of increasing the labor load of workers analyzing potions, reducing reliability, and increasing process complexity, so as to improve the reliability of electroplating. high durability, short plating time, high ductility and thermal shock reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

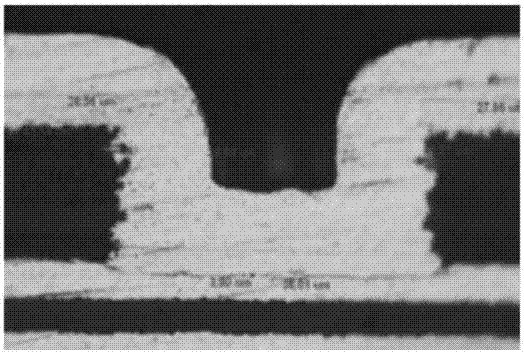

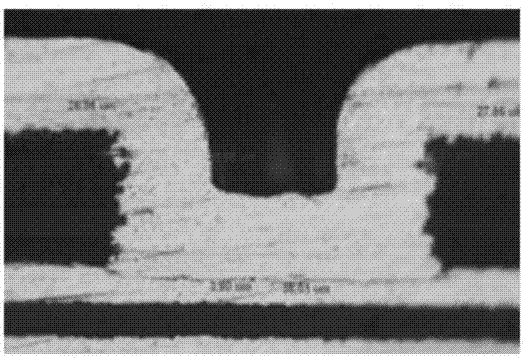

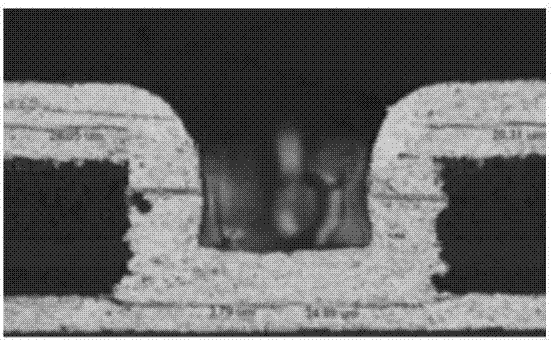

Image

Examples

Embodiment 1

[0040] This example uses a vertical plating process. The composition of the through-blind hole co-plating electroplating solution of the present embodiment is as follows:

[0041] The A component is anhydrous copper sulfate whose mass concentration is 100g / L;

[0042] Described B component is the sulfuric acid that mass concentration is 200g / L;

[0043] Described C component is the chloride that mass concentration is 150mg / L;

[0044] The D component is a mixture of sodium polydithiodipropanesulfonate, sodium 3-mercaptopropanesulfonate, and sodium N,N-dimethyldithiocarbonylpropanesulfonate.

[0045] The mass ratio of the A component:B component:C component:D component is 100:200:0.15:0.003.

[0046] Metallize the substrate with through holes and blind holes, and immerse the metallized substrate in the co-plating electroplating solution for the above-mentioned through and blind holes for electroplating. The ductility and thermal shock reliability of the substrate after copp...

Embodiment 2

[0048] This example uses a vertical plating process. The composition of the through-blind hole co-plating electroplating solution of the present embodiment is as follows:

[0049] The A component is anhydrous copper sulfate whose mass concentration is 100g / L;

[0050] Described B component is the sulfuric acid that mass concentration is 200g / L;

[0051] Described C component is the chloride that mass concentration is 150mg / L;

[0052] The D component is a mixture of sodium polydithiodipropane sulfonate, sodium 3-mercaptopropane sulfonate, inner salt of isothiourea propane sulfonate and 3-(benzothiazole-2-mercapto)-propane sulfonate ;

[0053] The E component is a mixture of polyethylene glycol, polypropylene alcohol and fatty amine polyoxyethylene ether.

[0054] The mass ratio of component A: component B: component C: component D: component E is 100:200:0.15:0.003:10.

[0055] The electroplating method to the substrate is the same as in Example 1. The ductility and ther...

Embodiment 3

[0057] This example uses a vertical plating process. The composition of the through-blind hole co-plating electroplating solution of the present embodiment is as follows:

[0058] The A component is anhydrous copper sulfate whose mass concentration is 100g / L;

[0059] Described B component is the sulfuric acid that mass concentration is 200g / L;

[0060] Described C component is the chloride that mass concentration is 150mg / L;

[0061] The D component is a mixture of sodium polydithiodipropanesulfonate and 3-mercaptopropanesulfonate;

[0062] The E component is fatty amine polyoxyethylene ether;

[0063] The F component is a mixture of polyethyleneimine, basic yellow and polyamine salt.

[0064] The mass ratio of component A: component B: component C: component D: component E: component F is 100:200:0.15:0.003:10:0.002.

[0065] The electroplating method to the substrate is the same as in Example 1. The ductility and thermal shock reliability of the substrate after copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com