Method for chemically plating surface of diamond with Ni and P in microwave-ultrasound combined mode

A technology of diamond particles and ultrasonic waves, which is applied in the field of microwave-ultrasonic combined electroless Ni-P plating on the surface of diamonds, can solve the problems of insufficient bonding strength between the coating and the diamond interface, insufficient smoothness of the coating surface, and agglomeration of diamond particles to achieve accelerated plating. Liquid reaction and coating deposition rate, enhanced mass transfer process, coating integrity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

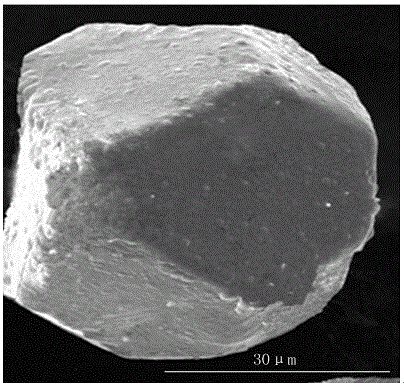

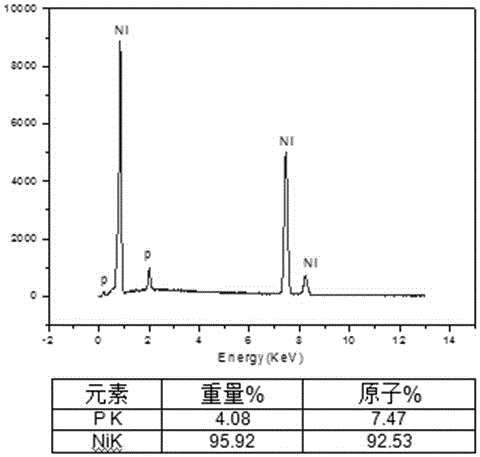

Embodiment 1

[0024] The method for microwave-ultrasonic combined electroless Ni-P plating on the diamond surface, its specific steps are as follows:

[0025] (1) First, boil 5g of diamond particles with a particle size of 120μm in 400ml of 10g / L NaOH solution to remove grease and dirt, rinse with distilled water for 2 to 3 times, and use the mass percentage of diamond particles that have been removed from grease and dirt to be 30% dilute HNO in 400ml 3 Boil in the solution for 30 minutes to roughen the surface of the diamond particles and form tiny concave surfaces on the surface of the diamond particles to facilitate the adsorption of metal ions and provide favorable conditions for the growth of the subsequent electroless metal deposition layer. Wash with distilled water 2 to 3 times;

[0026] (2) Put the roughened diamond particles in step (1) into 300 mL of colloidal palladium salt solution and stir them ultrasonically for 30 minutes, wash with distilled water to obtain diamond particle...

Embodiment 2

[0030] The method for microwave-ultrasonic combined electroless Ni-P plating on the diamond surface, its specific steps are as follows:

[0031] (1) First, boil 5g of diamond particles with a particle size of 20μm in 400ml of 10g / L NaOH solution to remove grease and dirt, rinse with distilled water for 2 to 3 times, and use the mass percentage of the diamond particles that have been removed from grease and dirt to be 30% dilute HNO in 400ml 3 Boil in the solution for 30 minutes to roughen the surface of the diamond particles and form tiny concave surfaces on the surface of the diamond particles to facilitate the adsorption of metal ions and provide favorable conditions for the subsequent growth of the electroless metal deposition layer. Wash with distilled water 2 to 3 times;

[0032] (2) Place the roughened diamond particles in step (1) in 300 mL of colloidal palladium salt solution and stir them ultrasonically for 30 minutes, wash with distilled water to obtain diamond parti...

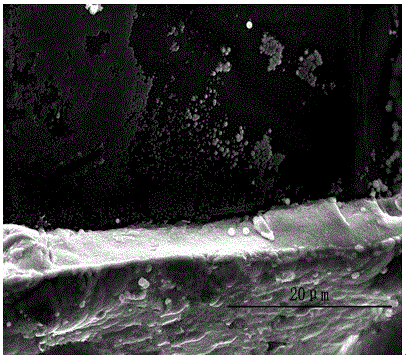

Embodiment 3

[0036] The method for microwave-ultrasonic combined electroless Ni-P plating on the diamond surface, its specific steps are as follows:

[0037] (1) First, boil 5g of diamond particles with a particle size of 10μm in 400ml of 10g / L NaOH solution to remove grease and dirt, rinse with distilled water for 2 to 3 times, and use the mass percentage of the diamond particles that have been removed from grease and dirt to be 30% dilute HNO in 400ml 3 Boil in the solution for 30 minutes to roughen the surface of the diamond particles and form tiny concave surfaces on the surface of the diamond particles to facilitate the adsorption of metal ions and provide favorable conditions for the subsequent growth of the electroless metal deposition layer. Wash with distilled water 2 to 3 times;

[0038] (2) Place the roughened diamond particles in step (1) in 300 mL of colloidal palladium salt solution and stir them ultrasonically for 30 minutes, wash with distilled water to obtain diamond parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com