Copper element modified carbon fiber reinforced copper-based contact material and preparation method thereof

A fiber-reinforced, contact material technology, applied in the direction of contact materials, metal material coating technology, contacts, etc., can solve the problems of material performance degradation, poor bonding state, etc., and achieve friction coefficient reduction, conductivity improvement, parameter easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Firstly, put the carbon fiber in a muffle furnace for burning and degumming, where the heating temperature is 400°C and the heating time is 30min.

[0048] Put the carbon fiber after degumming into NaOH with a concentration of 20g / L and NaOH with a concentration of 10g / L 2 CO 3 In the alkaline degreasing agent, the temperature of the water bath is 55°C, ultrasonically oscillated for 30 minutes, and washed with distilled water until neutral.

[0049] The degreased carbon fibers were placed in a mixture of concentrated sulfuric acid and concentrated nitric acid (volume ratio 2.5:1) and ultrasonically oscillated for 10 minutes, then placed in a collector-type constant temperature heating magnetic stirrer for 50 minutes, and the temperature of the water bath was 55 ° C. Wash with distilled water until neutral.

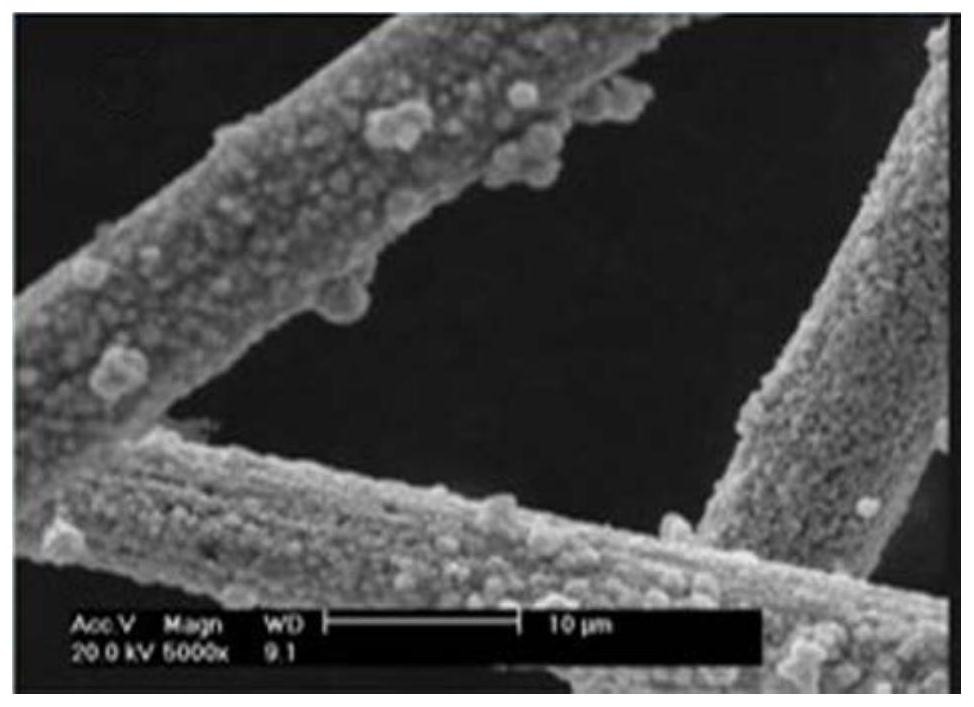

[0050] Place the roughened carbon fiber in 45g / L SnCl 2 and 85ml / L HCl mixed solution (volume ratio 1:1.2), using a collector type constant temperature heating m...

Embodiment 2

[0062] Put the carbon fiber in a muffle furnace for burning and degumming, where the heating temperature is 500°C and the heating time is 45min.

[0063] Put the carbon fiber after degumming into NaOH with a concentration of 30g / L and NaOH with a concentration of 15g / L 2 CO 3 In the alkaline degreasing agent, the temperature of the water bath is 60°C, ultrasonically oscillated for 35 minutes, and washed with distilled water until neutral.

[0064] The degreased carbon fiber was placed in a mixture of concentrated sulfuric acid and concentrated nitric acid (volume ratio 2.5:1) and ultrasonically oscillated for 15 minutes, then placed in a collector type constant temperature heating magnetic stirrer for 55 minutes, and the temperature of the water bath was 60 ° C. Wash with distilled water until neutral.

[0065] Place the roughened carbon fiber in 50g / L SnCl 2 and 90ml / L HCl mixed solution (volume ratio 1:1.2), using a collector type constant temperature heating magnetic sti...

Embodiment 3

[0072] The carbon fiber is placed in a muffle furnace for burning and degumming, where the heating temperature is 600°C and the heating time is 60 minutes.

[0073] Put the carbon fiber after degumming into NaOH with a concentration of 40g / L and NaOH with a concentration of 20g / L 2 CO 3 In the alkaline degreaser, the temperature of the water bath is 65°C, ultrasonically oscillated for 40 minutes, and washed with distilled water until neutral.

[0074] The degreased carbon fiber was placed in a mixture of concentrated sulfuric acid and concentrated nitric acid (volume ratio 2.5:1) and ultrasonically oscillated for 20 minutes, then placed in a collector type constant temperature heating magnetic stirrer for 60 minutes, and the temperature of the water bath was 65 ° C. Wash with distilled water until neutral.

[0075] Place the roughened carbon fiber in 55g / L SnCl 2 and 100ml / L HCl mixed solution (volume ratio 1:1.2), using a collector type constant temperature heating magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com