A kind of cyanide-free imitation gold electroplating solution and its magnesium alloy electroplating process

An electroplating process and electroplating solution technology, applied in the field of metal surface electroplating, can solve the problems of poor bonding force of electroplating imitation gold coating and high activity of magnesium alloy, and achieve the effects of short electroplating time, wide electrochemical window and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

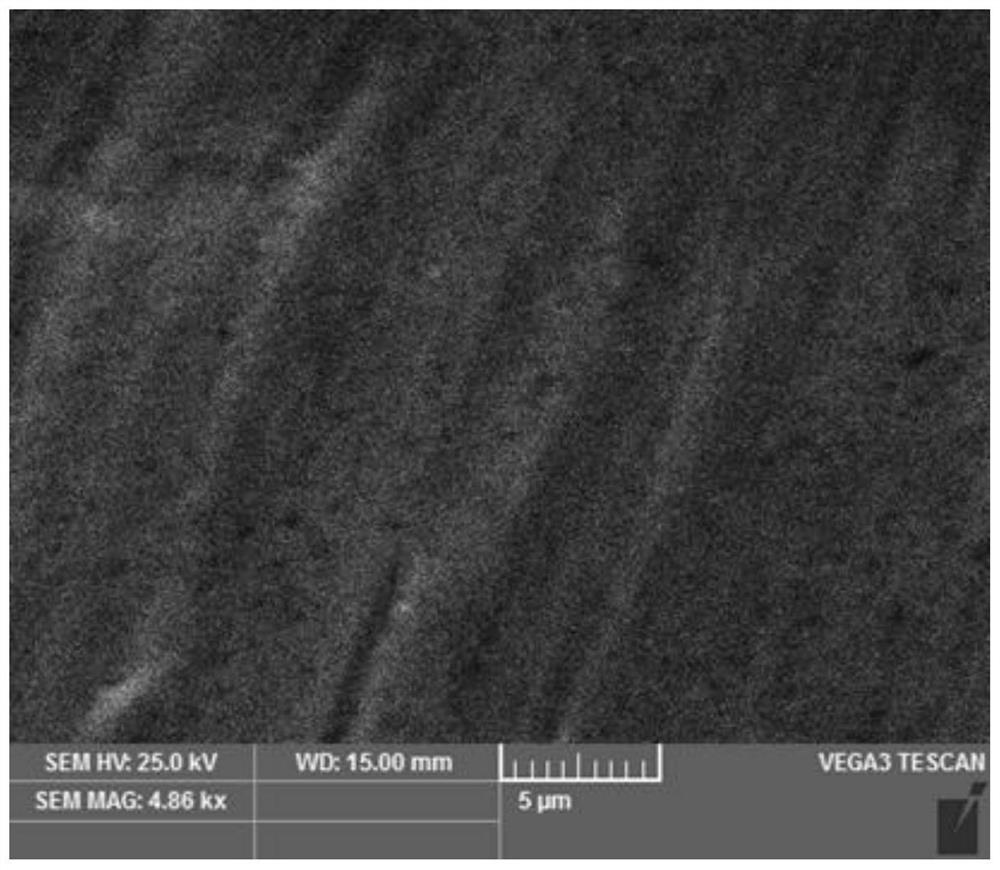

Image

Examples

Embodiment 1

[0033] The cyanide-free imitation gold electroplating solution of the present embodiment comprises the following components in every liter of electroplating solution: potassium pyrophosphate (K 4 P 2 o 7 ·3H 2 O) 240g / L, copper pyrophosphate (Cu 2 P 2 o 7 ) 20g / L, stannous pyrophosphate (Sn 2 P 2 o 7 ) 2.0g / L, zinc sulfate (ZnSO 4 ·7H 2 O) 40g / L, hydroxyethylidene diphosphonic acid (HEDP) 20g / L, AESS (fatty alcohol polyoxyethylene ether sulfosuccinic acid monoester disodium salt) 2mL / L and imidazole ionic liquid ([OMIM]HSO 4 ) 3mol / L, the solvent is water; the pH of the electroplating solution is adjusted to 8.5 by potassium pyrophosphate and potassium hydroxide.

[0034] The process steps of electroplating a cyanide-free imitation gold electroplating coating on the surface of magnesium alloy are as follows:

[0035] (1) Polish it, then undergo ultrasonic degreasing, pickling and activation treatment in sequence, degreasing agent: sodium hydroxide NaOH: 20g / L; sodiu...

Embodiment 2

[0040] The cyanide-free imitation gold electroplating solution of the present embodiment comprises the following components in every liter of electroplating solution: potassium pyrophosphate (K 4 P 2 o 7 ·3H 2 O) 300g / L, copper pyrophosphate (Cu 2 P 2 o 7 ) 24g / L, stannous pyrophosphate (Sn 2 P 2 o 7 ) 1.5g / L, zinc sulfate (ZnSO 4 ·7H 2 O) 50g / L, hydroxyethylidene diphosphonic acid (HEDP) 15g / L, AESS (fatty alcohol polyoxyethylene ether sulfosuccinic acid monoester disodium salt) 3mL / L and imidazole ionic liquid ([OMIM]HSO 4 ) 2mol / L, the solvent is water; the pH of the electroplating solution is adjusted to be 8 by potassium pyrophosphate and potassium hydroxide.

[0041] The process steps of electroplating a cyanide-free imitation gold electroplating coating on the surface of magnesium alloy are as follows:

[0042] (1) Polish it, then undergo ultrasonic degreasing, pickling and activation treatment in sequence, degreasing agent: sodium hydroxide (NaOH): 25g / L; so...

Embodiment 3

[0046] Cyanide-free imitation gold electroplating solution is identical with embodiment 1.

[0047] The process steps of the cyanide-free imitation gold electroplating coating on the magnesium alloy surface are basically the same as in Example 1, and the difference is that: after the galvanizing treatment of step (2), there is an extra step of bright copper plating, according to potassium pyrophosphate ( K 4 P 2 o 7 ) 200g / L, copper pyrophosphate (Cu 2 P 2 o 7 4H 2 (2) 50g / L, ammoniacal liquor 3mg / L, Polyethylene Glycol 10000 1g / L, be mixed with aqueous solution, regulate pH and be 8.5, obtain bright copper plating solution; Stir, room temperature, current density 0.8A / dm 2 Conditions for 6 minutes. The appearance of the imitation gold coating obtained in this embodiment is consistent with that of Example 1, and the appearance quality of the coating is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com