Large-aperture uniform optical filter and method for preparing same

A filter and uniformity technology, applied in the direction of filters, optics, optical components, etc., can solve the problems of high sensitivity and decreased filter transmittance, achieve uniformity improvement, shorten plating time, effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0032] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] The method can be used to make a double-cavity optical filter with a center wavelength of 532nm, and is also applicable to other optical filter films of any wavelength.

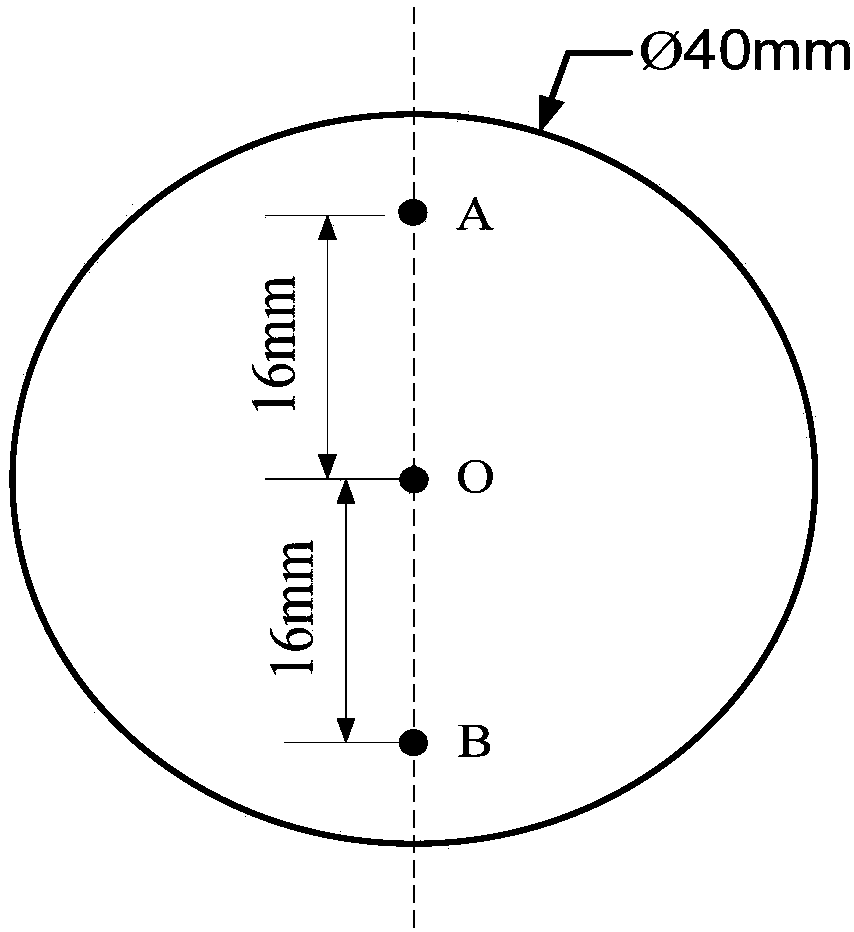

[0034] 1) Using fused silica with a diameter of Φ40mm and a thickness of 1mm as the substrate, the selected film material is mainly high refractive index material tantalum pentoxide (Ta 2 o 5 ) thin film and low refractive index material silicon dioxide (SiO 2 ) film, design reference wavelength λ0=532nm, unit optical thickness is 133nm.

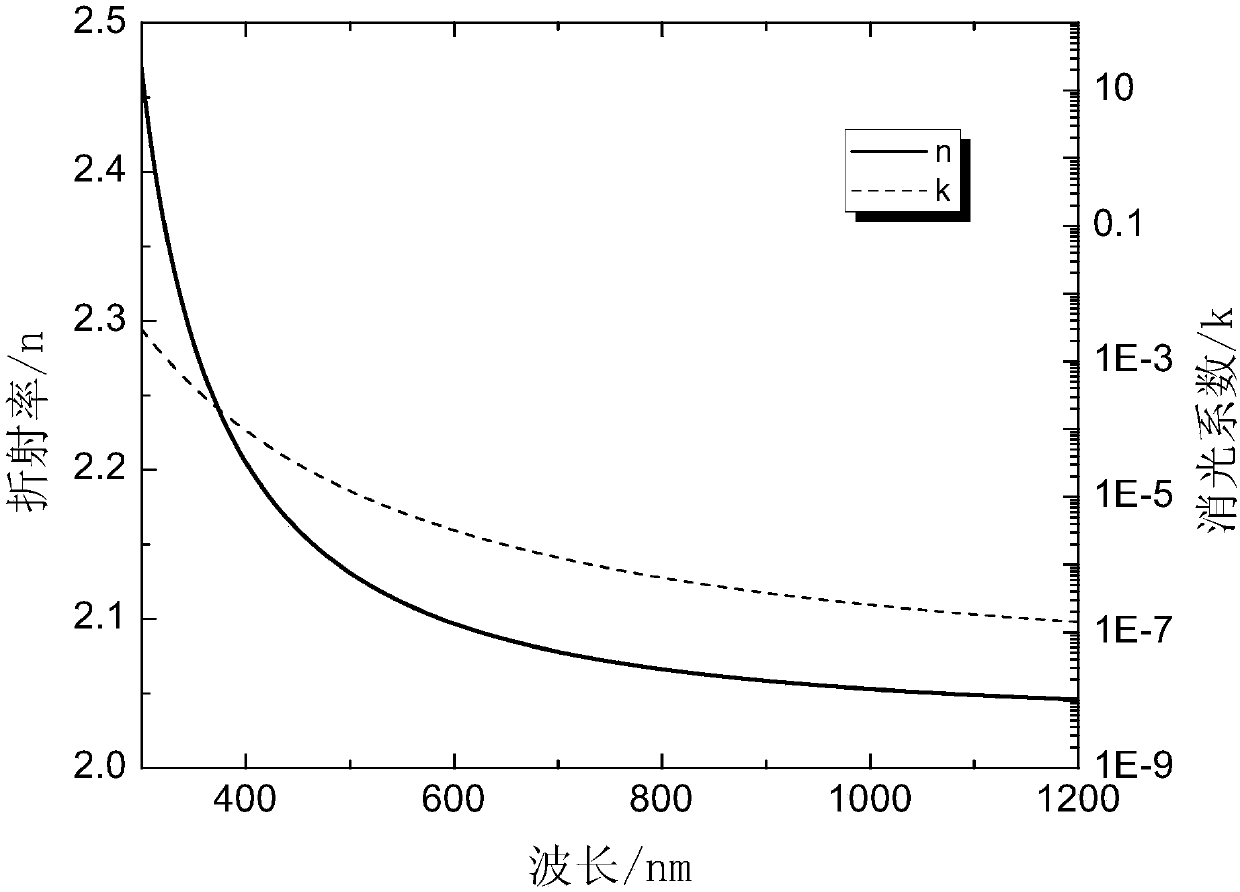

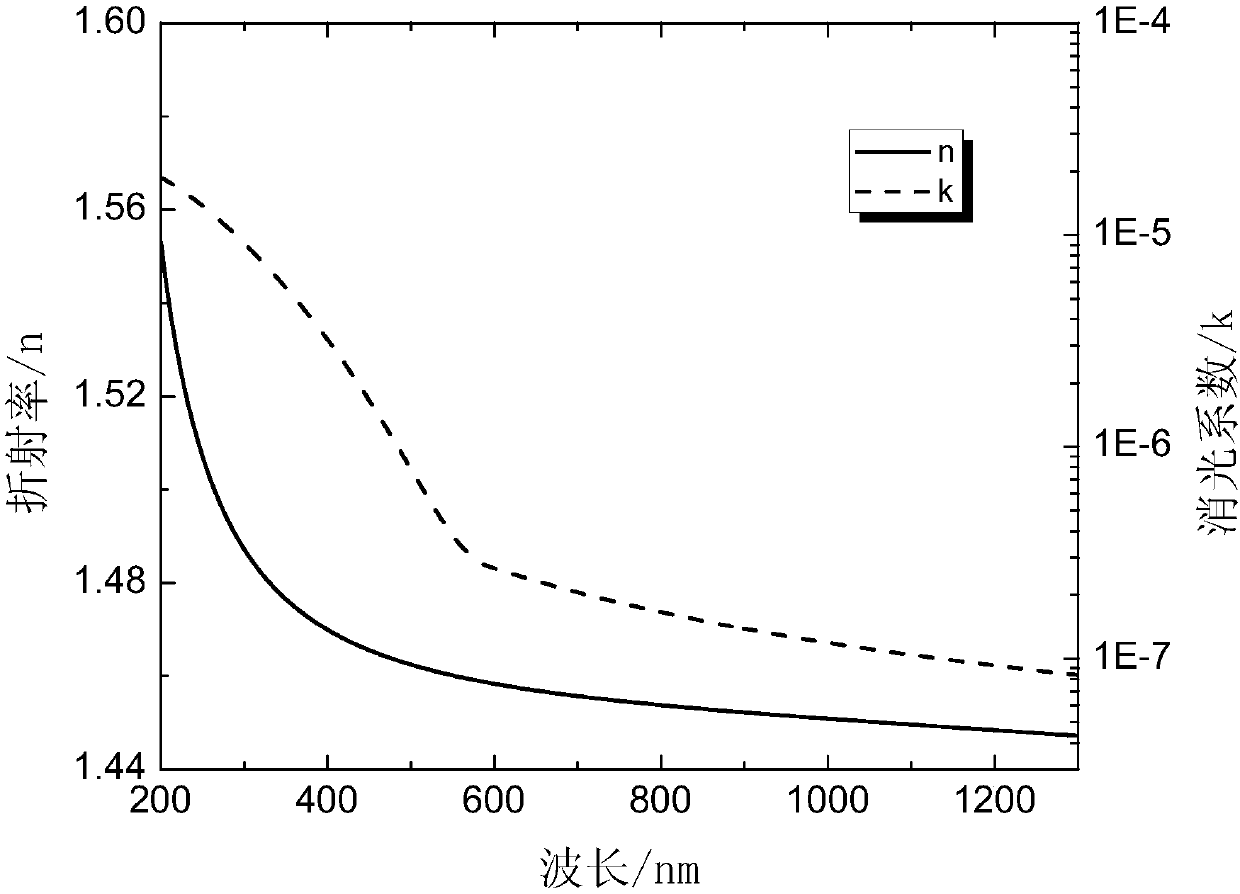

[0035] 2) Through single-layer thin film experiments, Ta 2 o 5 Refractive inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com