Multi-stage nickel plating process

A multi-stage, multi-stage technology, applied in the field of step-by-step electroplating parameter control, can solve problems such as high current, nickel layer burns, poor weldability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

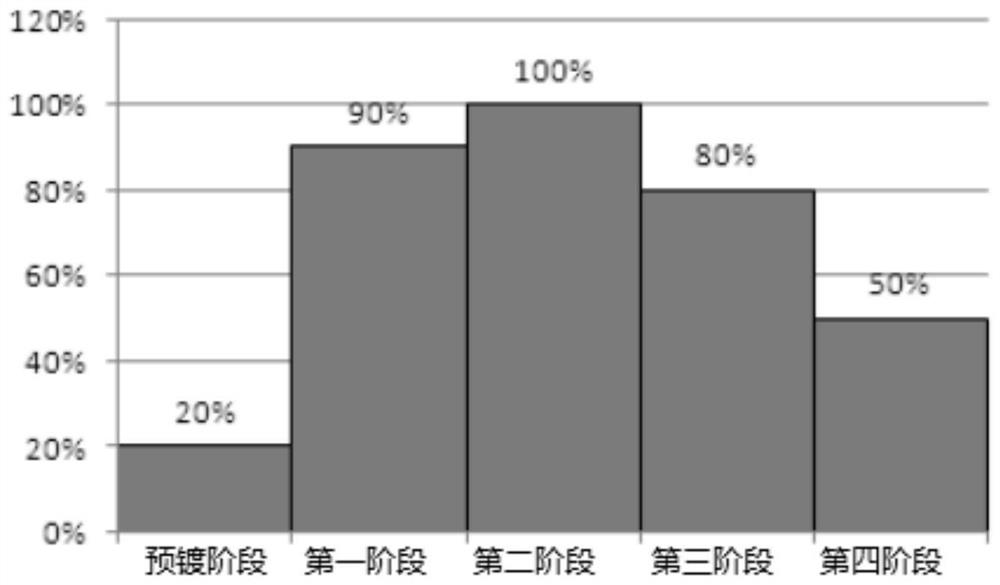

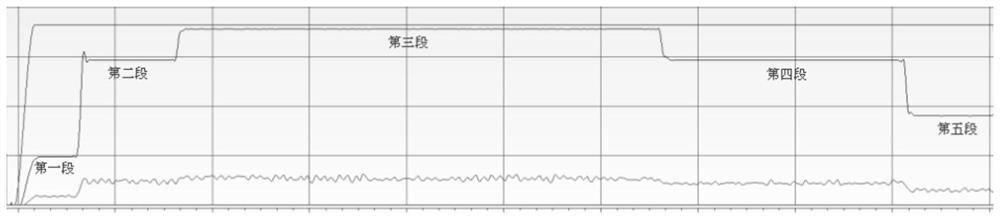

[0040] A kind of multi-stage nickel plating process provided by the present embodiment includes the following stages:

[0041] Pre-plating stage: current density is 0.12ASD, pre-plating is 300s, electroplating solution is nickel sulfamate 80g / L, nickel bromide 16g / L and boric acid 35g / L; pH is 4.2, temperature is 55℃, eccentric drum The speed is 14.5 rpm;

[0042] The first stage: According to the rate of 0.02ASD per second, the current density is increased to 0.54ASD; electroplating for 900s, the electroplating solution is nickel sulfamate 80g / L, nickel bromide 16g / L and boric acid 35g / L; pH is 4.2, The temperature is 55°C, and the rotational speed of the eccentric drum is 16.5 rpm;

[0043] The second stage: According to the rate of 0.01ASD per second, the current density is increased to 0.6ASD, electroplating for 4200s, the electroplating solution is 80g / L of nickel sulfamate, 16g / L of nickel bromide and 35g / L of boric acid; the pH is 4.2, The temperature is 55°C, and the...

Embodiment 2

[0048] A kind of multi-stage nickel plating process provided by the present embodiment includes the following stages:

[0049] Pre-plating stage: current density is 0.12ASD, pre-plating is 300s, electroplating solution is nickel sulfamate 100g / L, nickel bromide 7g / L and boric acid 50g / L; pH is 4.4, temperature is 55℃, eccentric drum The speed is 14.5 rpm;

[0050] The first stage: According to the rate of 0.02ASD per second, the current density is increased to 0.54ASD; electroplating for 900s, the electroplating solution is nickel sulfamate 80g / L, nickel bromide 16g / L and boric acid 35g / L; pH is 4.2, The temperature is 55°C, and the rotational speed of the eccentric drum is 16.5 rpm;

[0051] The second stage: According to the rate of 0.01ASD per second, the current density is increased to 0.6ASD, electroplating for 4200s, the electroplating solution is 80g / L of nickel sulfamate, 16g / L of nickel bromide and 35g / L of boric acid; the pH is 4.2, The temperature is 55°C, and the...

Embodiment 3

[0056] A kind of multi-stage nickel plating process provided by the present embodiment includes the following stages:

[0057] Pre-plating stage: current density is 0.12ASD, pre-plating is 300s, electroplating solution is nickel sulfamate 80g / L, nickel bromide 16g / L and boric acid 35g / L; pH is 4.2, temperature is 55℃, eccentric drum The speed is 16.5 rev / min;

[0058] The first stage: According to the rate of 0.02ASD per second, the current density is increased to 0.54ASD; electroplating for 900s, the electroplating solution is nickel sulfamate 80g / L, nickel bromide 16g / L and boric acid 35g / L; pH is 4.2, The temperature is 55°C, and the rotational speed of the eccentric drum is 16.5 rpm;

[0059] The second stage: According to the rate of 0.01ASD per second, the current density is increased to 0.6ASD, electroplating for 4200s, the electroplating solution is 80g / L of nickel sulfamate, 16g / L of nickel bromide and 35g / L of boric acid; the pH is 4.2, The temperature is 55°C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com