A multi-stage nickel plating process

A multi-stage, multi-stage technology, applied in the field of step-by-step electroplating parameter control, can solve the problems of tip discharge effect, nickel layer burn, poor weldability, etc., and achieve the effect of promoting surface smoothness, short electroplating time and good welding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

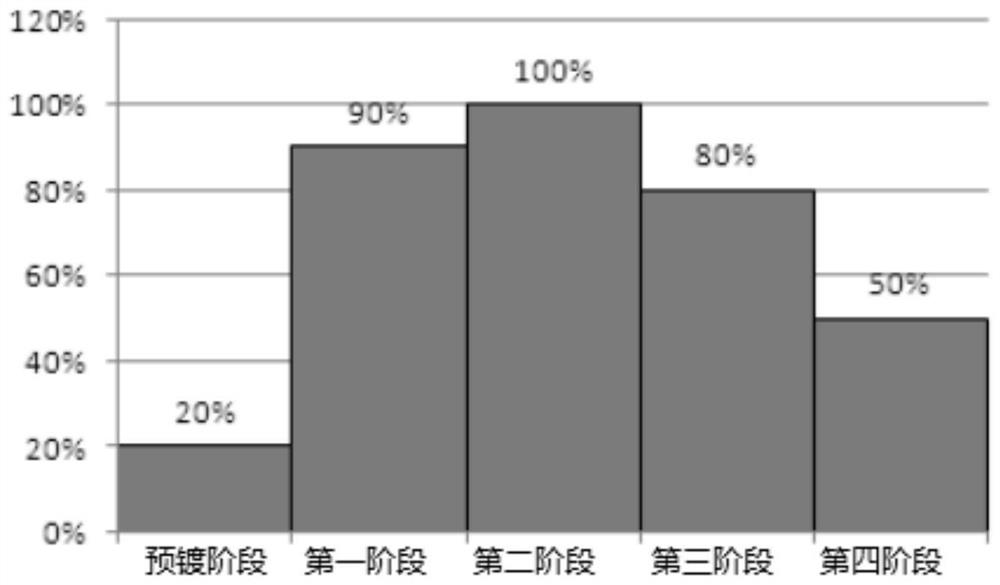

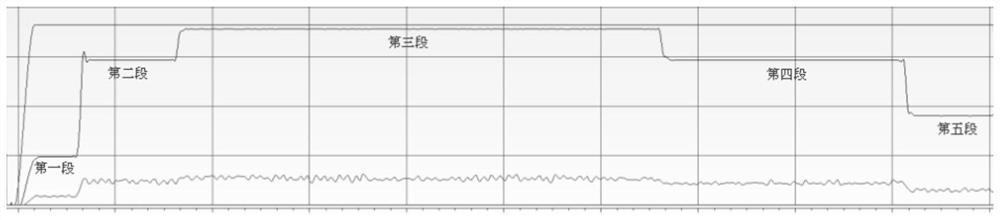

[0040] A kind of multi-stage nickel plating process provided by the present embodiment includes the following stages:

[0041] Pre-plating stage: current density is 0.12ASD, pre-plating is 300s, electroplating solution is nickel sulfamate 80g / L, nickel bromide 16g / L and boric acid 35g / L; pH is 4.2, temperature is 55℃, eccentric drum The speed is 14.5 rpm;

[0042] The first stage: According to the rate of 0.02ASD per second, the current density is increased to 0.54ASD; electroplating for 900s, the electroplating solution is nickel sulfamate 80g / L, nickel bromide 16g / L and boric acid 35g / L; pH is 4.2, The temperature is 55°C, and the rotational speed of the eccentric drum is 16.5 rpm;

[0043] The second stage: According to the rate of 0.01ASD per second, the current density is increased to 0.6ASD, electroplating for 4200s, the electroplating solution is 80g / L of nickel sulfamate, 16g / L of nickel bromide and 35g / L of boric acid; the pH is 4.2, The temperature is 55°C, and the...

Embodiment 2

[0048] A kind of multi-stage nickel plating process provided by the present embodiment includes the following stages:

[0049] Pre-plating stage: current density is 0.12ASD, pre-plating is 300s, electroplating solution is nickel sulfamate 100g / L, nickel bromide 7g / L and boric acid 50g / L; pH is 4.4, temperature is 55℃, eccentric drum The speed is 14.5 rpm;

[0050] The first stage: According to the rate of 0.02ASD per second, the current density is increased to 0.54ASD; electroplating for 900s, the electroplating solution is nickel sulfamate 80g / L, nickel bromide 16g / L and boric acid 35g / L; pH is 4.2, The temperature is 55°C, and the rotational speed of the eccentric drum is 16.5 rpm;

[0051] The second stage: According to the rate of 0.01ASD per second, the current density is increased to 0.6ASD, electroplating for 4200s, the electroplating solution is 80g / L of nickel sulfamate, 16g / L of nickel bromide and 35g / L of boric acid; the pH is 4.2, The temperature is 55°C, and the...

Embodiment 3

[0056] A kind of multi-stage nickel plating process provided by the present embodiment includes the following stages:

[0057] Pre-plating stage: current density is 0.12ASD, pre-plating is 300s, electroplating solution is nickel sulfamate 80g / L, nickel bromide 16g / L and boric acid 35g / L; pH is 4.2, temperature is 55℃, eccentric drum The speed is 16.5 rev / min;

[0058] The first stage: According to the rate of 0.02ASD per second, the current density is increased to 0.54ASD; electroplating for 900s, the electroplating solution is nickel sulfamate 80g / L, nickel bromide 16g / L and boric acid 35g / L; pH is 4.2, The temperature is 55°C, and the rotational speed of the eccentric drum is 16.5 rpm;

[0059] The second stage: According to the rate of 0.01ASD per second, the current density is increased to 0.6ASD, electroplating for 4200s, the electroplating solution is 80g / L of nickel sulfamate, 16g / L of nickel bromide and 35g / L of boric acid; the pH is 4.2, The temperature is 55°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com