Electroplating process of high-abrasion resistance corrosion-resistance Pd-Co gradient alloy for stainless steel surface

A gradient alloy and electroplating technology, which is applied in the field of alloy electroplating to achieve stable performance, no pinholes, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, industrial 316L (GB00Cr17Ni14Mo2) stainless steel plate electroplating Pd--Co gradient alloy:

[0029] (1) Pre-treatment: including grinding off the burrs on the rough surface, chemical degreasing, electrochemical activation, and deionized water rinsing.

[0030] (2) Immediately followed by electroplating Pd–Co gradient alloy, the composition of the plating solution is:

[0031] Palladium salt Pd(NH 3 ) 4 Cl 2 : The measurement is 5g / L based on the mass of Pd

[0032] NH 4 Cl: 50g / L

[0033] The mass percent concentration is 28% NH 3 ·H 2 O: 50ml / L

[0034] CoCl 2 ·6H 2 O: 16g / L

[0035] C 2 h 5 o 2 N: 50g / L

[0036] Saccharin: 1g / L

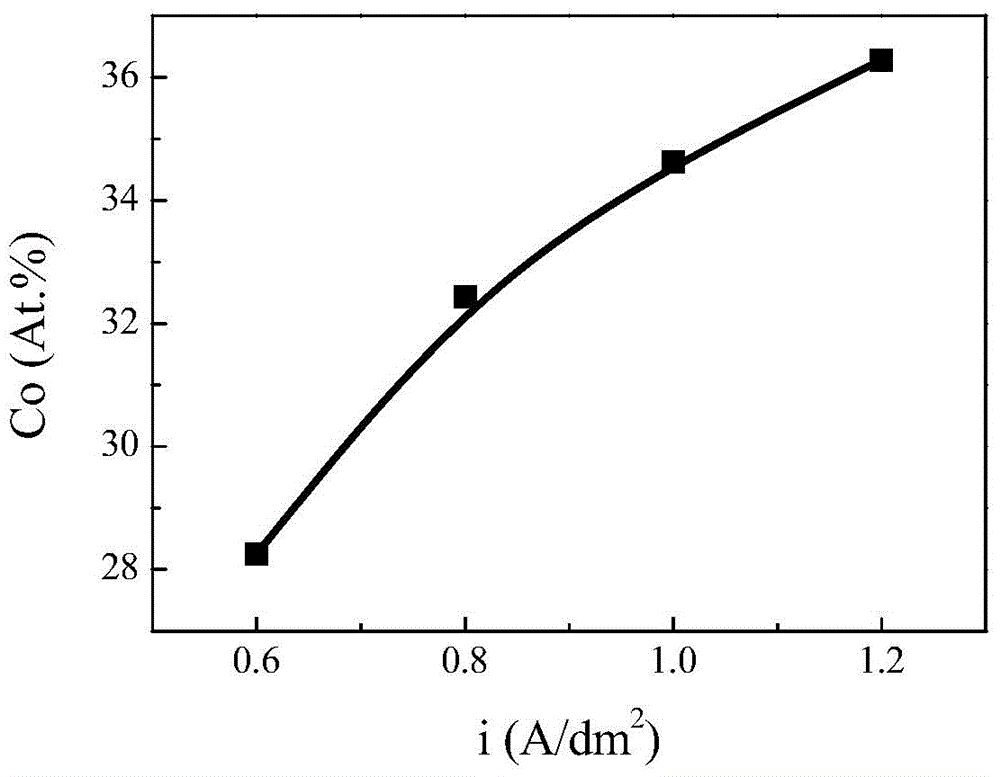

[0037] The electroplating method is: adjust the pH value of the plating solution to 8, and then use 0.6, 0.8, 1.0, 1.2A / dm 2 Electroplating at the current density for 2min.

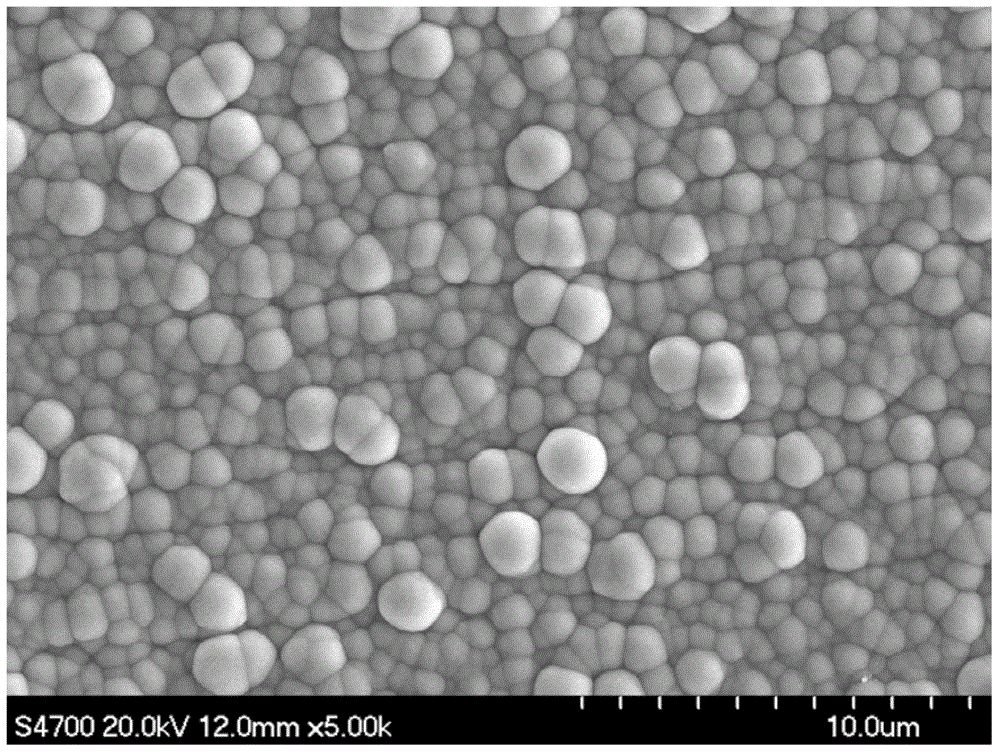

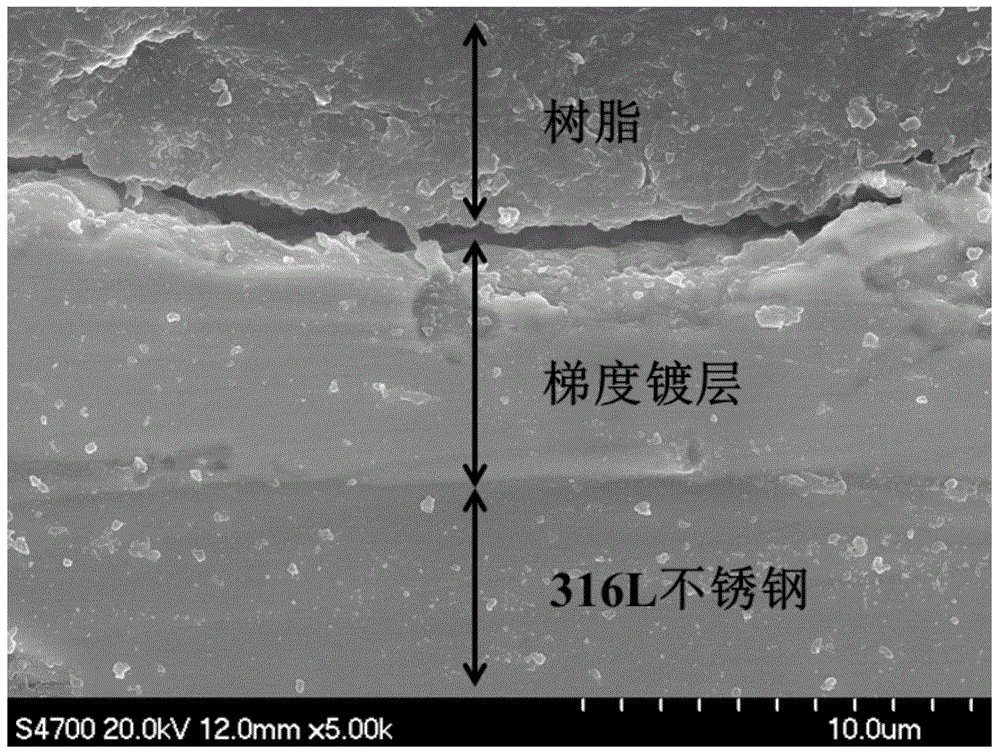

[0038] After the plating is completed, a coating with good bonding force, uniformity and excellent erosion and corrosion resistance is...

Embodiment 2

[0043] Embodiment 2, industrial 316L (GB00Cr17Ni14Mo2) stainless steel plate electroplating Pd--Co gradient alloy:

[0044] (1) Pre-treatment: including grinding off the burrs on the rough surface, chemical degreasing, electrochemical activation, and deionized water rinsing.

[0045](2) Immediately followed by electroplating Pd–Co gradient alloy, the composition of the plating solution is:

[0046] Palladium salt Pd(NH 3 ) 4 Cl 2 : Measured by the mass of Pd 10g / L

[0047] NH 4 Cl: 70g / L

[0048] The mass percent concentration is 28% NH 3 ·H 2 O: 80ml / L

[0049] CoCl 2 ·6H 2 O: 16g / L

[0050] C 2 h 5 o 2 N: 50g / L

[0051] Saccharin: 1g / L

[0052] The electroplating method is: adjust the pH value of the plating solution to 8, and then use 0.6, 0.8, 1.0, 1.2A / dm 2 Electroplating at the current density for 2min.

[0053] After the plating is completed, a coating with good bonding force, uniformity and excellent erosion and corrosion resistance is obtained. Vari...

Embodiment 3

[0058] Embodiment 3, industrial 316L (GB00Cr17Ni14Mo2) stainless steel plate electroplating Pd--Co gradient alloy:

[0059] (1) Pre-treatment: including grinding off the burrs on the rough surface, chemical degreasing, electrochemical activation, and deionized water rinsing.

[0060] (2) Immediately followed by electroplating Pd–Co gradient alloy, the composition of the plating solution is:

[0061] Palladium salt Pd(NH 3 ) 4 Cl 2 : The measurement is 5g / L based on the mass of Pd

[0062] NH 4 Cl: 50g / L

[0063] The mass percent concentration is 28% NH 3 ·H 2 O: 50ml / L

[0064] CoCl 2 ·6H 2 O: 16g / L

[0065] C 2 h 5 o 2 N: 50g / L

[0066] Saccharin: 1g / L

[0067] The electroplating method is: adjust the pH value of the plating solution to 8, and then use 0.5, 0.8, 1.1, 1.4A / dm 2 Electroplating at the current density for 3min.

[0068] After the plating is completed, a coating with good bonding force, uniformity and excellent erosion and corrosion resistance is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com