A Multilayer Nickel Electroplating Additive with Improved Stability

An electroplating additive and multi-layer nickel technology, which is applied in the field of electroplating industry, can solve problems such as cumbersome process and insufficient stability of electroplating solution, and achieve the effects of good brightness, low current density, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

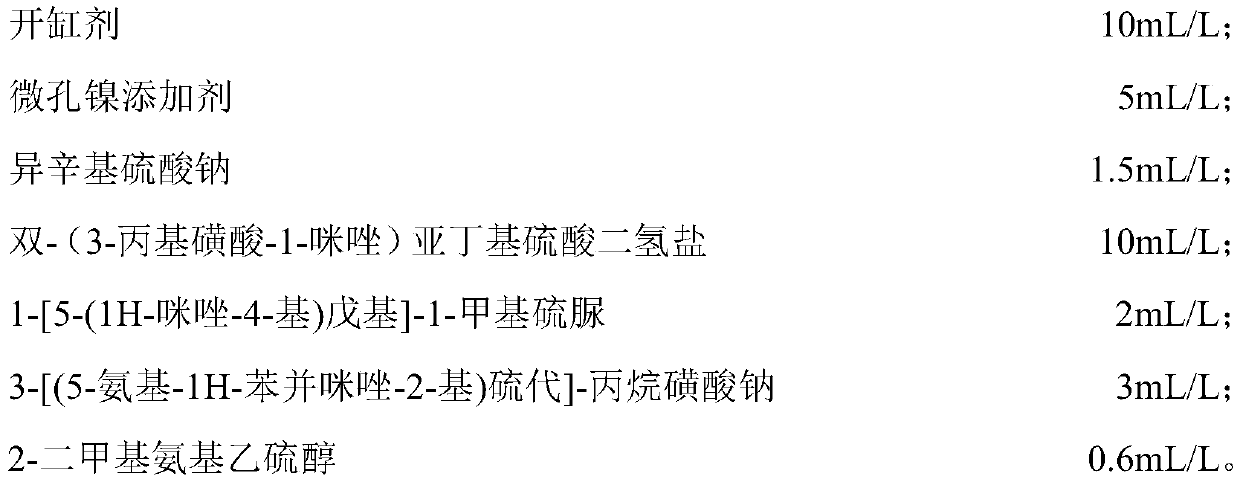

[0041]Embodiment 1 provides a kind of multilayer nickel electroplating additive that improves stability, in terms of the concentration in the plating solution, its preparation raw material comprises:

[0042]

[0043] The raw materials for the preparation of the vat opener include: 30 g / L of sulfosalicylic acid, 40 g / L of 1,4-butynediol, 50 g / L of chloral hydrate, and the solvent is deionized water.

[0044] The raw materials for the preparation of the microporous nickel additive include: polyetheramine T403 4g / L, polyetheramine T5000 2g / L, and the solvent is deionized water.

[0045] This example also provides a nickel plating process containing the above multilayer nickel plating additives:

[0046] Add the above-mentioned multi-layer nickel electroplating additive to the electroplating bath in an amount of 1.2mL / L. During nickel plating, the bath temperature is 58°C and the current density is 17mA / cm 2 , The plating time is 23 minutes.

Embodiment 2

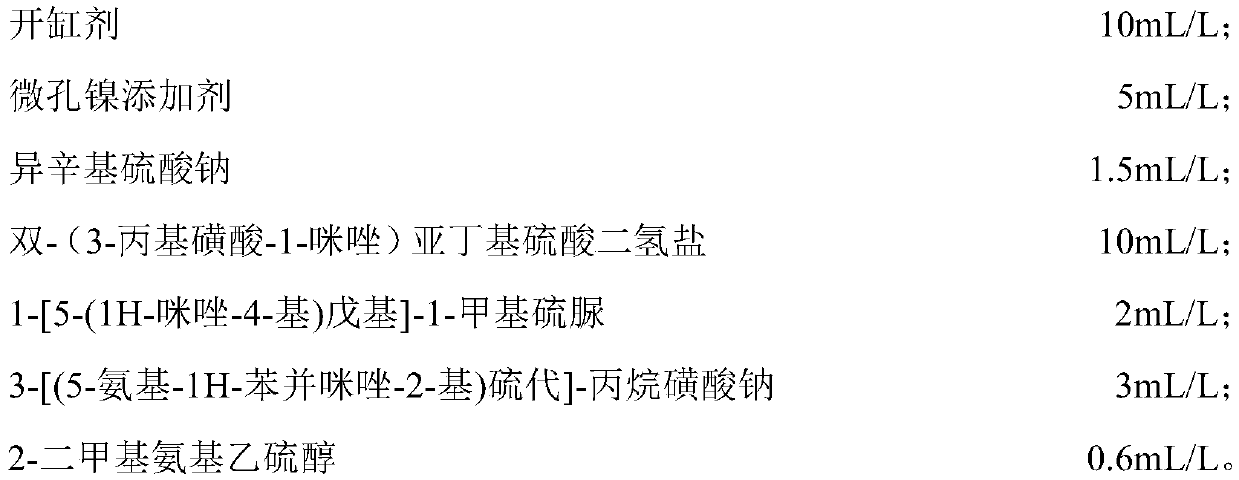

[0048] Embodiment 2 provides a kind of multilayer nickel electroplating additive that improves stability, in terms of the concentration in the plating solution, its preparation raw material comprises:

[0049]

[0050] The raw materials for the preparation of the vat opener include: 30 g / L of sulfosalicylic acid, 40 g / L of 1,4-butynediol, 50 g / L of chloral hydrate, and the solvent is deionized water.

[0051] The raw materials for the preparation of the microporous nickel additive include: polyetheramine T403 4g / L, polyetheramine T5000 2g / L, and the solvent is deionized water.

[0052] This example also provides a nickel plating process containing the above multilayer nickel plating additives:

[0053] Add the above-mentioned multi-layer nickel electroplating additive to the electroplating bath in an amount of 1.2mL / L. During nickel plating, the bath temperature is 56°C and the current density is 16mA / cm 2 , plating time is 20 minutes.

Embodiment 3

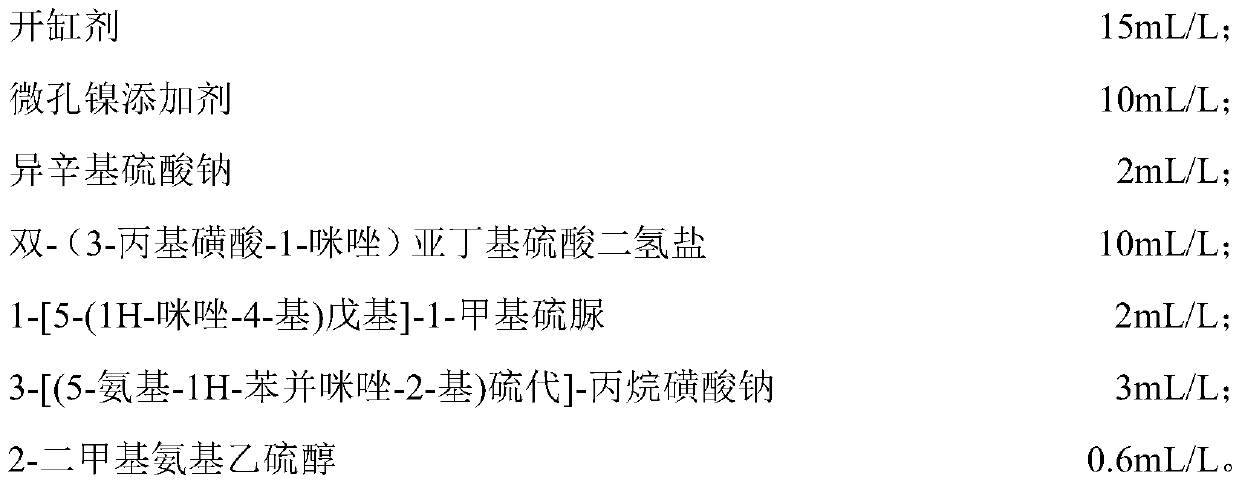

[0055] Embodiment 3 provides a kind of multilayer nickel electroplating additive that improves stability, in terms of the concentration in the plating solution, its preparation raw material comprises:

[0056]

[0057] The raw materials for the preparation of the vat opener include: 30 g / L of sulfosalicylic acid, 40 g / L of 1,4-butynediol, 50 g / L of chloral hydrate, and the solvent is deionized water.

[0058] The raw materials for the preparation of the microporous nickel additive include: polyetheramine T403 4g / L, polyetheramine T5000 2g / L, and the solvent is deionized water.

[0059] This example also provides a nickel plating process containing the above multilayer nickel plating additives:

[0060] Add the above-mentioned multi-layer nickel electroplating additive to the electroplating bath in an amount of 1.2mL / L. During nickel plating, the bath temperature is 58°C and the current density is 17mA / cm 2 , The plating time is 23 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com