A kind of nickel plating solution applied to printed circuit board and electroplating nickel method thereof

A printed circuit board, electroplating nickel technology, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of electroplating cannot be carried out normally, the plating layer has no bonding force with the substrate, and the stability of the electroplating nickel solution is poor, so as to achieve good Colloidal properties and dispersing effects, accelerating the activation reaction speed, and avoiding the effect of metal ion deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

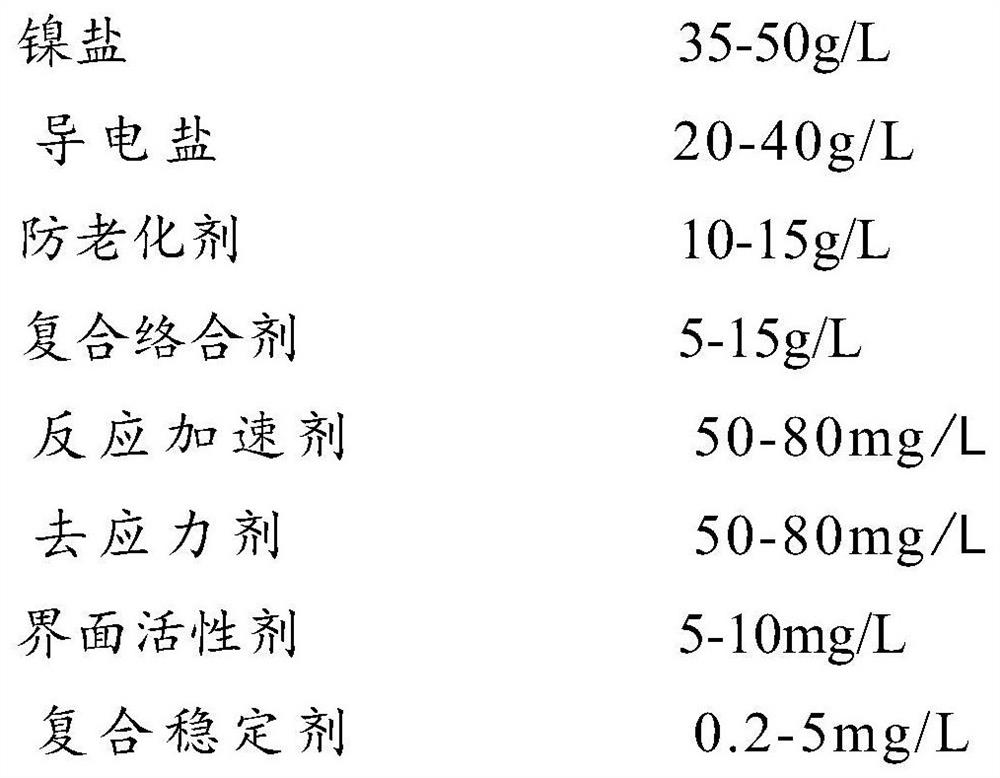

[0062] A kind of nickel plating solution that is applied to printed circuit board, comprises the component of following mass concentration:

[0063]

[0064]The composite complexing agent includes A component and B component, and the A component and the B component are 3:1 according to the mass concentration ratio; the A component includes citric acid whose mass concentration is 2g / L, 1g / L of ammonium acetate, 2.25g / L of malic acid; component B is a mixture of polyacrylamide, aminocarboxylic acid resin, hyperbranched polyurethane sulfonate, β-nicotinamide adenine dinucleotide, mass concentration It is 1.75g / L. The nickel plating solution can be formed by adjusting the pH value of the solution to 4.5 and buffering with a pH buffer agent with a mass concentration of 25%.

[0065] Using the nickel plating solution prepared by this component, the printed circuit board is electroplated by this nickel electroplating method, the temperature of the first stage is 70°C, and the de...

Embodiment 2

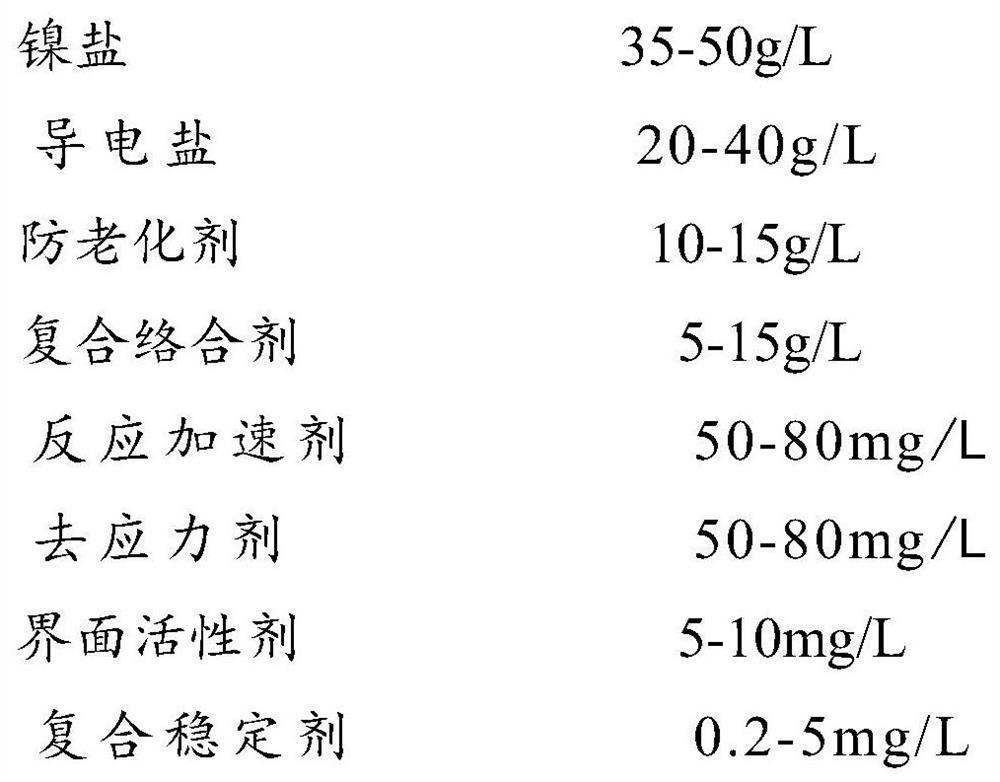

[0070] A kind of nickel plating solution that is applied to printed circuit board, comprises the component of following mass concentration:

[0071]

[0072] The composite complexing agent includes A component and B component, and the A component and the B component are in a mass concentration ratio of 3:2; the A component includes citric acid with a mass concentration of 1g / L, 1g / L of ammonium acetate, 1g / L of malic acid; the mass concentration of component B is 2g / L. The nickel plating solution can be formed after the pH value of the solution is adjusted to 4.6 with a pH buffer agent with a mass concentration of 25%.

[0073] Using the nickel plating solution prepared by this component, the printed circuit board is electroplated by this nickel electroplating method. The first stage temperature is 60°C, the time is 10 minutes, and the density is 2A / dm 2 , the thickness of the nickel layer obtained in the first stage is 4 microns, and the entire electroplating process tak...

Embodiment 3

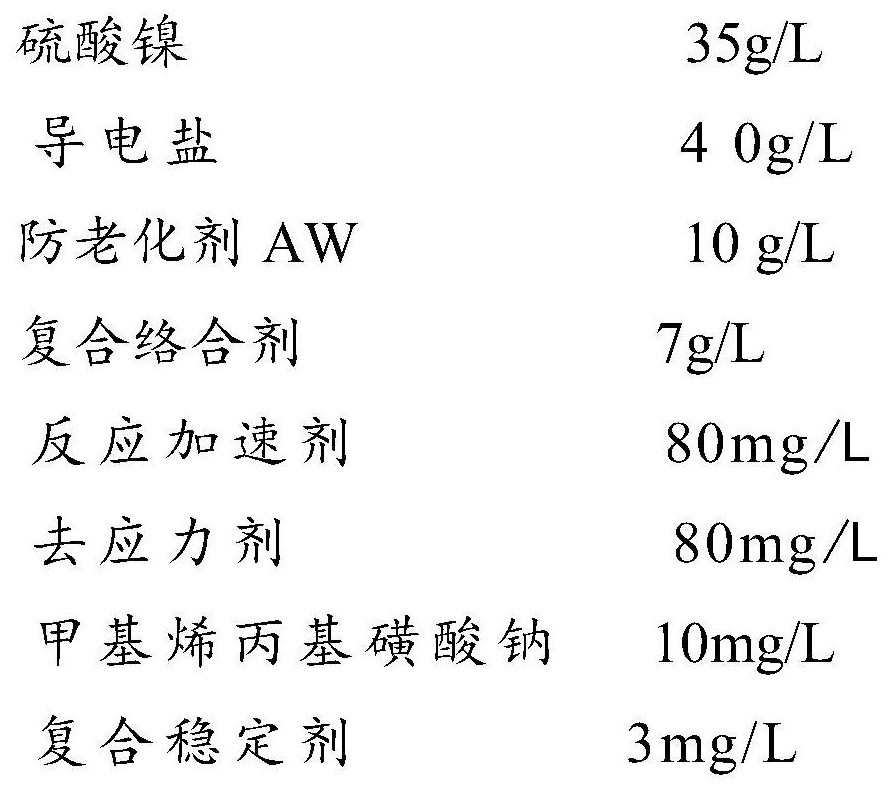

[0078] A kind of nickel plating solution that is applied to printed circuit board, comprises the component of following mass concentration:

[0079]

[0080] The composite complexing agent includes A component and B component, and the A component and the B component are 3:2 according to the mass concentration ratio; the A component includes citric acid whose mass concentration is 4g / L, 2g / L of ammonium acetate, 3g / L of malic acid; the mass concentration of component B is 6g / L. The nickel plating solution can be formed after the pH value of the solution is adjusted to 4.6 with a pH buffer agent with a mass concentration of 25%.

[0081] Using the nickel plating solution prepared by this component, the printed circuit board is electroplated by this nickel electroplating method. The temperature of the first stage is 65 ° C, the time is 5 minutes, and the density is 2A / dm 2 , the thickness of the nickel layer obtained in the first stage is 4 microns; the temperature of the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com